Not only the old buildings, but the new buildings create problems for their owners. This is due primarily to the uneven floor surfaces. Such a base may not be used for packing any type of floor covering. Consequently, have to find a way to level the floor well. An excellent material for this is a mixture for floor leveling. They have a sufficient amount of benefits due to members of the components, increase the quality of the final solution.

Features

Screed in new homes is not always characterized by flatness. But it is very important for high-quality flooring flooring, as well as the appearance of any room. Even the decoration of such a surface does not make sense to do. All defects, which are hollows and bumps, It will be much later at the finish coating.

If the composition of the solution used to perform the screed was prepared directly on site, the currently used dry mixtures for floor leveling, in which it is enough to add a certain amount of water. They have all the necessary ingredients to produce quality results. Besides proportions fully observed their ratio to one another.

Floor leveling compounds - bystrotverdeyushchie compositions, having plasticity, excellent fluidity. Usually they are in the form of dry mixes or concentrates, which contain appropriate additives. It only remains to add the required amount of water and pour over the entire area of the premises. Any unevenness of the subfloor will be hidden, the surface is perfectly smooth.

Advantages premixed

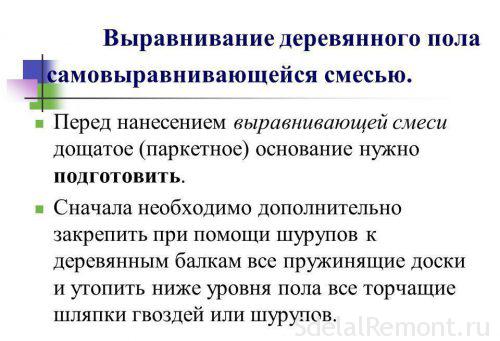

The binder and the main component of dry mixture is usually a cement or gypsum. In addition, they contain aggregates - sand. finished compositions, than and different, contain further additives, imparting certain properties and characteristics of the final solution. They are constantly being improved, whereby the range of application expands with each passing day. Leveling can be not only a concrete base, but also of wood, arrange Floor, on the street, on the terrace and at industrial sites.

You can pick up the dry mixture floor leveling, which will not require finishing on total. I.e, will topcoat. But in most cases, used as the base layer, a kind of layer. This is not due to a special appeal, imbibition of moisture and fat.

Several attention should be paid to the advantages, which has self-leveling floor mix:

- Durability of the result.

- Longer lifetime.

- Good adhesion layer, followed by.

- Power solution obtained even with a minimum layer, allowing not affect the height of the room.

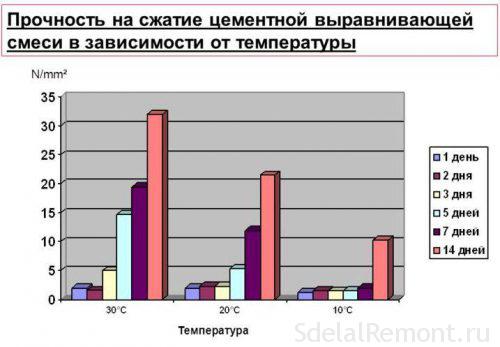

- Instant dates solution hardening.

- No drawdowns after curing.

- There is no need to closely monitor the "maturation" process, spray and increase the level of humidity.

- Any substrate can be aligned due to the huge range of pre-mixes for the self-leveling floor.

- The uniformity of distribution of ready-made solution for the entire area of the room.

Alternative

Factory mixes may be replaced by a cheaper option. Enough to take part cement, add the three parts of sand, with a fraction not exceeding 5 mm. Initially, the mixing of these two components, and then you can add water. As a result, the solution can be used for surface leveling screeds and. It is important to monitor the proportions of the component and select only the best of them to obtain the desired result. But even in this case, the result will not always please. It should be added, that the drying of the solution is almost a month, it may crack, prosest and show all its other negative qualities.

If no other options are "homemade" blend, for its better ductility can be added into the PVA glue. This will cause rapid hardening solution for screed, and subsequently will have to work hard when cleaning the base.

All this suggests that, it is best not to fooling with the proportions and expert advice to improve the quality of sand and cement mortar surface, and buy mixtures for floor leveling finish.

Composition of dry mixes

There are two large groups of dry building mixes self-leveling floor:

- On the basis of cement. A more extensive range of applications due to the fear of lack of moisture.

- On the basis of plaster. Due to the instantaneous water absorption, such solutions are best done in dry conditions (living rooms).

gypsum popularity is not going anywhere because of its environmental friendliness, included in the composition of the natural components. Gypsum products for floor leveling possess excellent level of thermal insulation, that allows them to use the system underfloor heating. They are able to take in the moisture, if it is too in the room and give with insufficient. It is perfect for such a floor covering, as the parquet, laminate. Cracks of them will not happen.

When leveling mixture is used, self-leveling floor turns out very thin and durable. In this specific additive can be included in its composition, adds certain properties and characteristics to the finished solution. Supplements and will change the composition of the self-leveling floor. Cracks almost never will be formed on the dried basis. The exception is only the failure to comply with self-leveling floor device technology.

Varieties self-leveling compositions

Dry leveling compounds for floors are divided into two broad categories depending on the way to work with them:

- Self-aligning mixtures. They are able to independently distributed on the floor surface without any extra effort. Ready solution after pouring is horizontal and provides a result of a perfectly flat surface. For large areas use a special pump. Due to the rapid solidification, most often they are used for leveling the base and preparation for flooring flooring. But this mixture after mixing can not be topcoat because of appearance, active dust separation substances, excellent moisture absorption and oils.

- Requiring additional leveling by trowel. Here a person takes an active part in the device floor screed. They are called "rough" mix. Suitable devices for floor heating and smoothing irregularities massive floor surface.

designation

The difference between the compositions prepared mixture is performed in the functions. Thicker layers of the final accepted to arrange sex with significant drops, potholes, which is difficult in other ways to close up. However, there are finishing, when filled with a thin self-leveling floor. In the latter case, however, and the cost will increase several times.

Mixtures are not always adapted to the subsequent finishing. This applies to their device on the street, on the terrace, veranda, steps. The thickness of the base layer of the lowest of the screed 1 cm and comes to 8. There already exist and fillers, allow to reduce the price: ground granite, expanded, coarse sand. The fluidity of their reduced, thereby unlikely to get a perfectly flat surface.

When a small drop height subfloor may be used immediately finishing compositions. true, can not in this case, forget about their high cost. Their selection will depend on the humidity in the room, the impact during operation.

Repair tile is performed using elastic mixtures. The cement mixture for leveling the floor and adapted to reconstruct the wooden support, asphalt coating. Self-leveling mixtures promote the "tightening" level different floors of the apartment (laminate and tile).

manufacturers

Visit the shop is very difficult to choose the right mix for floor leveling. The range is very large and requires further attention and study each individual producer.

Popular manufacturer "Teplolux". He is ready to meet all expectations of the customer, wishing to arrange warm floor under the floor or floor finishing layer inlet.

For high quality smooth surface, should pay attention to the trademark «Vetonit». In addition to underfloor heating, they can be used to tie a wooden support, old tiles and other similar surface. Perfect for wet rooms, which do not affect the quality of the mixture in the ready-made. Solidification process takes only a few hours.

there are cases, when the surface of the room is so ugly, that requires a great deal of attention from the artist. In this situation, come to the aid miners thick self-leveling floor, able to provide a strong and durable surface after drying.

For laying wiring, cable, the choice must be stopped to "Niplayn" brands and "Startolayn". They are also able to arrange a flat floor over the entire area in the room.

It is difficult to determine the order, which blend is best for floor leveling. Each of them has a certain set of qualities, adapted for a specific premises with the provision of a set of positive qualities. experts assert, that if a base layer and a self-leveling floor finish, it should be made from a blend of one of the manufacturers, which should be followed in carrying out installation.

Right choice

Good leveling floor mix must be selected in view of the customer requirements. Selection is carried out under a single room and taking into account indicators of humidity and temperature. Crucial can play and the drying time of the finished solution. Especially such a factor is required for tight deadlines repair room.

Despite self-leveling floor thick layer even helps to provide a high surface quality and reliability. These floors are very easy to operate, since they do not require backbreaking attention.  When completely dry, have no impact on human health. It is necessary to watch only in the process of drying, when there is an allocation of a large amount of harmful substances.

When completely dry, have no impact on human health. It is necessary to watch only in the process of drying, when there is an allocation of a large amount of harmful substances.

Floor leveling compound for preparing very easily. Similarly, the base installation is done. It is enough to follow the recommendations of the manufacturer. Advice from the experts will make the final choice in favor of a particular type of self-leveling compounds. They will know all about it, as you have to deal with them all the time.

In no case can not pour water into the dry mix for floor leveling in more, to obtain a volume of the solution. It immediately reduce all performance and quality when dry. Following the instructions exactly will help to get a really high quality results.

If there are no minimal knowledge in this area of the construction sector, it is better to entrust the execution of works to professionals. Pay for their services, not have to spend your own time and worry about the outcome. It will be cheaper to do just that, than later to spend huge forces and means for the dismantling of the inlet floor due to violations of device technology.

cost of

Ready for floor leveling mix have different prices, what influence certain factors:

- qualitative characteristics.

- Composition.

- functions.

- Manufacturer.

Each customer must himself decide on the, which floor leveling mixtures select. But special attention should be paid shelf-life, which can be approached in the near future. Sometimes sellers put a product on sale with discounts. Better to pay a somewhat higher amount for brand, but to get really high-quality material for device self-leveling floor. In addition we recommend to watch the video on choosing self-leveling floor.