Construction companies have long chosen self-leveling floors, are only gaining popularity among customers. With their help achieve an excellent result is obtained by the quality and strength of the base, while spending the minimum amount of time and effort. But the main part of the success will depend on the materials used, selecting the appropriate manufacturer. Every self-leveling flooring materials have a slightly different. All will depend on the main component of the mixture and the additives present in composition.

Basis for sex

The basis for self-leveling floor compositions may be cement, various polymers, as well as epoxy resins. Also as part of the cement material will have different components, plasticizers such as. The latter are used for, to a ready solution has become more flexible and capable of self spread evenly. In addition, the plasticizer helps to reduce the cost of the finished mortar. Scope of leveling floors - industrial objects, as well as commercial premises.

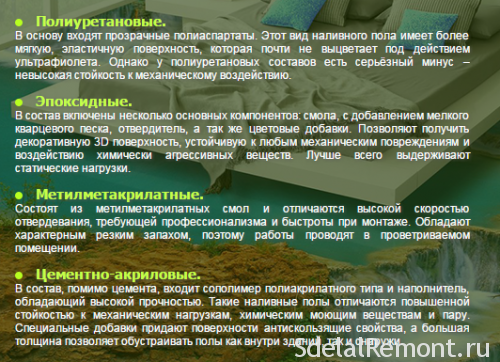

The most reliable and high-strength plastics are Self-leveling floors. The composition of the mixture is switched polyurethane, making ready solution universal in application. Due to this component is a mixture of different characteristics and properties for future solution.

Better quality is typical for epoxy self-leveling floor, which due to the composition have a somewhat greater cost among other possible options. Each of the types of self-leveling floor has its drawbacks. But in most cases they are associated with poor performing the installation and failure to comply with conditions of mixing, proportions.

Materials used

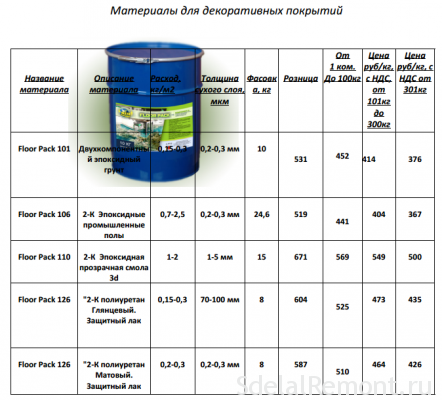

Initial action by pouring Self-leveling floors - quality training grounds. Already here should worry about, to buy the necessary materials. First of all we are talking about a primer. There is one very good rule of thumb - you need to choose those materials to fill the floor, which correspond to a single manufacturer.  This allows you to get the same quality at all stages of the work. Each manufacturer may recommend even, that and what to combine, to get a good result. These tips should listen. Here is based on experimental tests, which showed an excellent combination of material between a. Forumnye advisers while doing everything at random, will they have it or not.

This allows you to get the same quality at all stages of the work. Each manufacturer may recommend even, that and what to combine, to get a good result. These tips should listen. Here is based on experimental tests, which showed an excellent combination of material between a. Forumnye advisers while doing everything at random, will they have it or not.

You can not forget about waterproofing. It applies a damper tape for floor screed, to casting after solidification is not cracked upon expansion under the effect of temperature changes. In some cases, depending on the situation, It can be used in reinforced floor screed. Some people say, that you can do without it. But if the base layer is arranged, the grid only to strengthen and give a subsequent layer excellent foundation. The most popular tape for floor screed, made of nylon.

To topcoat has acquired a certain color, Mixing should be in solution add such components, both concentrates and corresponding color masterbatches.

As the sealing mastic may be acquired from polymeric substances. After drying the base layer self-leveling floor It can be seen even small cracks on surface.  To resolve this use the special glue. In this case, the final coating will be perfectly smooth and will not in operation errors.

To resolve this use the special glue. In this case, the final coating will be perfectly smooth and will not in operation errors.

according to the results, should make every effort to long life poured floor. An excellent material is varnish here, which cover the entire surface. It allows you to protect the floor from mechanical impact, and gives it a shiny appearance.

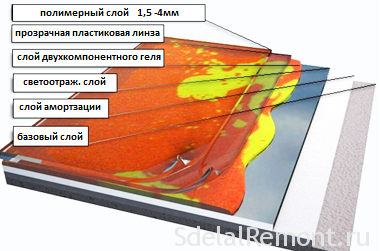

Materials for the 3d floor

You might think, that apply a completely different materials 3d floor, another tape for self-leveling floor. But they are not much different from each other. true, It can be divided into two large groups:

- Used in the coating. This is primarily a mixture of. For the 3d floor the best choice would be a two-component polymer (tinted or transparent), created on the basis of polyurethane or epoxy. It allows to prepare a solution of, needed to fill the floor. You can select some 12 colors different polymers, which are suitable for interior rooms, in which the work is performed.

- Necessary for the performance of work. There was isolated as the main tools (rollers, kraskostupy, Wipers, rule and TD).

The chips are used as additional materials for flooring 3d, pictures, Mural, tinsel, coins, etc.. They contribute to the beautification of the surface, that previously in general almost no one paid attention. floor screed reinforcement will be necessary in this case,, if the ground floor has a height error, differences, potholes and other defects.

Composition 3d drawing

Particular attention is paid to the figure at the device 3d sexes. More popular - the printed patterns on the photo printer (scenery, own photo, wildlife, etc.). They will correspond to the square, which is poured into the room. When the screed installation in industrial or commercial premises popular logos of firms, original characters, hieroglyphs, imagery, letters, etc.. As are used in studio apartments. The picture can be drawn and self, to order. In such a case will depend on the number of colors and shades therein. Will have to acquire or two colors for the black-and-white image or a set - for color.

Area not play a role at the device 3d sexes. Materials will be completely identical to it. There may be additions, which depend on the final figure, technology its execution. Starting coating thus can not do without beacons, nivelirov, levels. If needed and arranged a damper tape self-leveling floor will be more high-quality. Since it will not change its appearance over time.

Damper tape when pouring the floor have to settle for the reason, that helps to compensate for changes in the surface of the building progress, which can not be avoided.

Instruments

There is a minimum set of tools, which are applied to the device self-leveling floor in any room. It includes:

- Rollers for floor leveling (sinteponovye, needle).

- Wipers.

- Spatula with teeth.

- Corresponding to the size of the container.

- Level.

- For safety gloves, respirator, mokrostupy.

- Drill with a mixer for mixing the solution.

- Sander if necessary.

- Lighthouses depending on the type of self-leveling floor.

Each of them has a specific role in the installation of self-leveling floor, responsible for a certain stage of works. They should read more, to have an idea and produce a quality choice when visiting DIY stores.

The choice of container

Dimensions of working bucket or barrel should be chosen as large as possible. The solution is mixed therein, which not only should be enough for all the work room, but also for the uniform distribution of mixture components between a, Mixing with water. As a result, a homogeneous fluid mass should get.

Tank volume is usually chosen so, so that it could be at a time to add a mixture of the bag (weight 25 kg) and a corresponding amount of water. a bucket should be chosen according to design, a basin or barrel, to be easily interfere solution without the formation of splashes, ie better deep, than a.

It is worth noting, that the metal containers are much more expensive, than plastic, while heavy weight, which leads to some problems when performing casting. For this reason, the best option - a plastic bucket or bowl, with all the positive qualities.

needle roller

Sam roller can be fixed on the handle completely any, including the length of. Selection of the final product will depend on the artist. Its main goal - removal of air bubbles from the solution after pouring.

Needle Roller for Self-leveling floors It can not be applied in that case, if the solution starts to set. We can only damage the surface. So everything should be done immediately and without loss of time. For this reason, experts recommend working with team-mates: 1 - knead, 2 - leveled, 3 - passes the roller.

Make the handle of the two areas, are independent from each other. If desired, one motion can increase its length by half, or vice versa. Everything will depend on the need during casting. The work roll can be done throughout the room, while being in one place - in the middle.

It is worth noting, that there is another roller for self-leveling floor - when applied to the primer prepares the surface for better adhesion. He should be the appropriate nap - not less 1.2-1.5 cm. In this case everything will be done efficiently and quickly. The solution can be fastened securely to the base after filling.

So it is very important to know the, a roller for floor leveling choose. All will depend on the thickness of the layer of self-leveling floor, desired properties and characteristics.

Tips on shoes

These devices are also called "cat". On the bottom will be enough a few thorns, to navigate through the newly grouted. They are fixed on the shoe, in which the person works, and allow you to move the screed surface without damaging it. Their value an average of 1000 rubles.

There is a possibility to perform such packing at once, performing self-leveling floor. Blanks should be two - on each leg. As the material is water-resistant plywood. They are screwed screws or screws for furniture, that will be on hand. Fixation on the shoes is performed by means of an adhesive tape, which is very easy to unstick will, if necessary,. The material for any selected nozzles, load capacity artist and moisture from the solution.

Application equipment

It is not always possible to quickly and accurately perform self-leveling floor. The paper used and associated equipment. The area of the room in this case must be at least 100 m2. Among isolated ad:

- Ugloshlifmashinka.

- industrial vacuum cleaner.

- mosaic grinder.

In such a case it would still need a drill with a mixer for mixing the solution, as well as various tools for working: gloves, respirator, knee pads, etc.. It is worth noting, that security measures should always be followed in working with Polymer Flooring. Mixtures in the resulting solution is isolated huge amount of harmful substances to complete drying. Despite the short time for hardening the surface (several hours), all this period should be protected from fumes, not to get poisoned.

Professional advice

Not everyone knows about, whether it is necessary to reinforce the floor screed in the apartment. But experts do not hope for over the quality of the finished solution for the self-leveling floors and advise, especially when large differences in elevation area, reinforced self-leveling floor. This improves the quality of the frozen solution, giving it strength and durability. But the reinforced floor screed in the apartment? For this purpose there are enough funds, used in construction: reinforcing mesh, nylon, adding special components in the solution during its kneading.

Not only careful preparation, but also the chosen material (quality, manufacturer, recommendations) affect the outcome. You can not regret while no funds, if you need a durable self-leveling floor.

You can never give up tips and advice specialists. They are not exactly bad prompt, having great practical experience.