Very often happens, if the floor base has a large number of dents, cracks, spalling, which account for a long time to close up. Thus it is necessary to wait a certain time until the solution has dried, to begin filling of the base layer. An alternative to this is the use of a new generation of blends, and implement a self-leveling floor mix fill. These floors have many advantages, who excel in strength concrete and screed.

Advantages and disadvantages

Leveling the floor self-leveling compounds is very easy and simple. Sufficiently kneaded with addition of water, then pour the ready solution on the basis of. The result is a really smooth surface, in addition to many other major positive qualities:

- Instant drying the prepared solution after pouring.

- A few hours later, you can safely move on the surface.

- Even inexperienced person is able to perform a fill, with no experience.

- Laying of floor covering of any kind can be started after day.

- No shrinkage of the solution does not occur. In this case, it becomes very hard and able to withstand wear and tear, mechanical stress.

- They are ideal for low spaces, with a small distance between the floor and the ceiling. Minimum tie layer may be equal to 5 mm.

It is impossible to get around in this point and disadvantages, that may be encountered during the casting floor self-leveling compounds. The very foundation should carefully prepare before the start of work. No dirt or dust should not be. Otherwise, the quality of the dried base can be forgotten. It is necessary to have at least an idea on how to perform the installation screed, so as not to collide with the dismantling.

Costs not only to go to work on filling, but also for the purchase of the mixture itself. It is worth noting, that price is not very small. You need to take personal safety precautions when performing casting, as even minor drops in contact with human skin causes burns. Besides, huge amount of harmful substances released to complete drying, a mixture itself has high flammability level.

Looking at the existing disadvantages, it can be concluded that, that with the right approach and the equipment can be easily avoided. The main thing to do everything with the mind and get excellent results.

Application area

pour leveling floor possible not only to fit under the base level, but also for other areas, having a narrow specifics. This primer base, getting rid of possible dust, improved surface structure, to be processed.  And then, due to the rapid drying of the finished solution, do not have time to appear and form shrinkage cracks. Water thoroughly to spend money on curing the mixture and does not get into the ground.

And then, due to the rapid drying of the finished solution, do not have time to appear and form shrinkage cracks. Water thoroughly to spend money on curing the mixture and does not get into the ground.

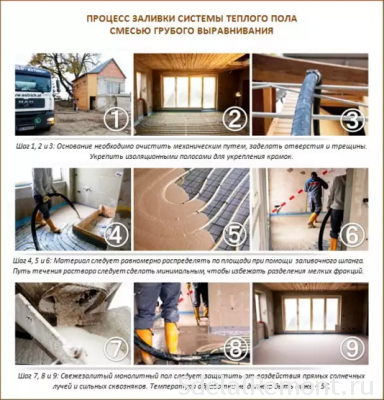

You can meet with this notion, as rough rovniteli. With their help, run rough floors, even if, when it implemented screed on "warm floor" or simply by the system.

Types mixtures

The composition of the mixture will depend on certain conditions, as well as to arrange the room. There are some items, are worth paying attention to at the time, when they visit the store to purchase a self-leveling compounds:

- Dryness in the room (humidity level).

- The use of decorative trim as an additional element.

- Contacting subsequently with water (bathroom, kitchen, restroom).

- Owning mixture further advantages: sound absorption, anti-slip, increased level of heat insulation.

- Application of chemicals, household chemicals after installation for washing the floor.

- The base for the floor and his ability to pick up moisture Statement.

- Align self-leveling floor mix for floor covering or as a finishing layer.

When this undecided, You can proceed to further selection for the mixture. Depending on the composition, it will have certain qualities and characteristics, which are necessary in a particular case in the implementation of installation.

As a primer or a surface suitable for dedusting a mixture based on cement. They are low-cost. Due to the thin layer, the maximum term sex life is three years. Among the advantages, you can select different levels of adhesion to subsequent layers self-leveling floor, as the foundation may even be wet surface, able to withstand frost and low temperatures, no cracking after drying. But still full of strength of the solution is achieved only after 3-4 weeks after potting, and the appearance is not attractive. It is best to use some dyes.

For "Warm" floor excellent embodiment is a mixture of gypsum-based. Greater demands on the surface there is no, but a ready solution in the end provide excellent thermal conductivity qualities. The advantages include environmentally friendly and speedy drying of the surface after pouring. the main thing, that the base was dry and the corresponding space. In this case, anhydrite screed can be made even at the level of 10 cm from the base. There are no restrictions here are not available. Most popular is the domestic production of "miners" mixtures, are applicable not only for machine filling device, but also a manual.

Pour the self-leveling flooring mixture on the basis of epoxy resins can be to produce large positive qualities. But they also have their drawbacks, which include a low degree of wear counter, cracks may form on the external impact, at a liquid contact to the surface, it becomes very slippery. Scope - chemical laboratories. But it is unlikely they will be able to please the owner in the kitchen or bathroom.

Alignment floors filled polymer based on a sufficient number of pluses:

- The ability to remain unchanged at temperature jumps.

- duration of operation. All qualities are retained at the initial level.

- Easily withstand load, vibration, pounding. This allows them to fill in the storerooms, as well as in industry.

- The high degree of sound insulation and waterproofing.

It is worth noting, such mixtures are expensive, and very demanding process for preparation of the base fill, which must be dry to the same.

So before, how to align the floor with a mixture of, should stop its specific embodiment,, to get the desired result.

Work tool

Acquisition of the desired amount of the mixture would depend on the base, his status and the number of defects.  If a self-leveling finishing surface leveling mixture, it is useful in the drill head and mixer, special containers for a certain amount of mixing solution for, putty knife, whereby the mixture will be distributed uniformly over the entire surface, aeration roller, able to remove formed at the time of the mixing of air bubbles.

If a self-leveling finishing surface leveling mixture, it is useful in the drill head and mixer, special containers for a certain amount of mixing solution for, putty knife, whereby the mixture will be distributed uniformly over the entire surface, aeration roller, able to remove formed at the time of the mixing of air bubbles.

Depending on the situation, which performs self-leveling leveling floor mix, Work may include fixing the damper tape around the perimeter of the room.

Until that moment, how to choose an appropriate cushion, you need to know about, which is about the thickness of the fill layer self-leveling floor.

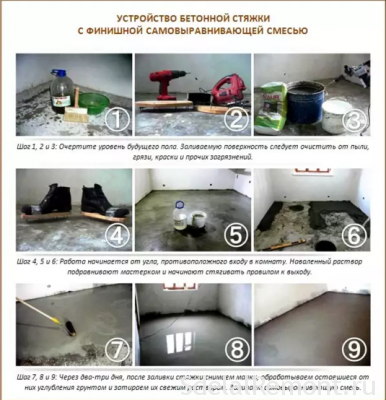

Substrate preparation

Fill with a mixture of self-leveling floor has one important requirement - high-quality training grounds. It is worth every effort, until that moment, how to perform the distribution of floor space solution. The sequence of work, their volume, It will depend on the base. If we have a concrete floor, it is necessary to inspect the surface. When it crumbles and collapses, the tie is better to remove and pour it all over again. In the presence of large cracks in area, they need to embroider, primed surface and then proceed to installation. Do not be amiss to make a waterproofing layer. In addition, the perimeter sizing damper tape, thus avoiding cracking drying solution.

Should know about, how to pour a leveling floor. Such mixtures are optimally used in that case, When the height differences do not exceed 20-30 mm. Also it should not be critical failure surface.

Ideal - to fill in rough screed, and only then stir the mixture for. The sequence of work will not be broken, and the finished result - reliable and durable floor.

Particular attention is paid to priming base, which contributes to better adhesion. From it will depend on the quality of the finishing floor, poured self-leveling compounds. there are moments, When the primer is very easily absorbed into the subfloor. In this case, repeat the priming for at least one address, that was the result.

wooden surface

You can save the situation, even if, If alignment is necessary self-leveling floor mix with wooden base. Boards covered prepared solution and allow to perform the following qualitative finishing layer. The main thing is to prepare high quality base.

The board must be attached to the joists, and the existing seams sealed with acrylic mass.  On top is covered with a waterproof floor primer. No harm will then lay a reinforcing grid, fixed to the wood stapler. Difficulties there is no no, but in the end will not only smooth, but also qualitative subfloor.

On top is covered with a waterproof floor primer. No harm will then lay a reinforcing grid, fixed to the wood stapler. Difficulties there is no no, but in the end will not only smooth, but also qualitative subfloor.

Do not be amiss in this self-clean several floor elements and make sure, that there is no mold, fungus underneath. Putty damaged areas can filings with liquid nails.

mixture

The process of cooking liquor from any kind of mixture looks identical. The dry components are added to the previously prepared container of water. Stirring is carried out using a drill with a special nozzle. After obtaining a homogeneous mass, should give her to wait 2-3 minutes, and then mix again. Will only have time in time to put a ready solution to the floor surface, until the polymerization process is started (usually no more than 60 minutes). Solidification process prescribed in the recommendations of the manufacturer.

Negligent sellers are trying to put forward those bags of ready mix, whose expiry date. With this need to be careful when buying, special, if he fills the process happens after a certain time.

We must be complied with the conditions, to Fill leveling the floor to get a quality:

- Mixing of the solution carried out at room temperature in the range 10-25 degrees.

It should be maintained at the same level for a certain time.

It should be maintained at the same level for a certain time. - The water used has a temperature above 10 degrees.

- The maximum level of humidity in the room - 80%. This should close the door and window openings, that there is no extraneous wind and drafts.

- To dry the cast solution does not include the battery and the system "warm floor".

Allowed grouting in large spaces stripes, arranged parallel to each other. But it is important to comply with the maximum spacing between adjacent sections - no more 10 minutes. To avoid premature drying of the floor is better to involve the assistant in work.

consumption

Before, how to align self-leveling floor, it is necessary to determine the amount of material used in the work. Each manufacturer specifies the flow of solution, bearing in mind, that the thickness of the screed will be 1 mm. Already from this it follows a start in preparing. But still in practice confronted with the, that the perfectly flat surface can not be obtained even after the putty. Consequently, calculation of the best do it yourself.

Determined surface curvature (the largest and smallest). From these parameters, the average value is taken, after which there is multiplication by an approximate ratio of recesses to the whole area of the room.

In this way, determined null layer and a coating. For the coating layer should set the parameters of reinforcing mesh, insulating materials and other. Sum of the thicknesses of the cover layer forms (approximately).

Material costs will impact the type of surface, the mixture, calculations of thicknesses of layers used in the work, as well as the total area of the premises. In any case, it turns only an approximate index required amount of dry mix for mixing a solution of. More precise amount obtained in the exercise of mounting. The only way to get an answer to that, how to align self-leveling flooring mixture.

process alignment

Not everyone knows, how to align the floor self-leveling compounds. There are no special difficulties, important to adhere to the technology and the sequence of each of the stages. Do not be amiss expose beacons, the choice of a specific embodiment of which will depend on the circumstances.

Fill the finished solution should be to a level beacons. After that there is leveling it across the floor area by means of regulations or spatula. Then immediately cleaned air bubbles, which could be formed from the mixture with water. For this purpose the needle roller. needle length will depend on the layer thickness self-leveling floor.

After pouring a few days should maintain the temperature in the room, that specified by the manufacturer. We can not allow drafts and sudden changes in humidity level. The solution should be dry and grab.

When no idea, how to align the floor self-leveling compounds, it is best to seek professional help. It will be much more profitable, than remodel, and the time take slightly less.

Leveling the floor with a mixture of self-leveling is performed instantly and without the use of special equipment. Suffice it to have a certain set of tools and the result will please everyone.