Despite the huge number of positive qualities of self-leveling floor, with the passage of time or poor installation may appear different defects. But not everyone with this has information about, how did it all resolve, available recovery methods. The fact, that in certain situations it can be done in-house, not to spend money to hire experts in this area.

Tools for repair

To begin to prepare all the necessary material and tools. Only a complete list will help to repair the self-leveling floor with high quality and in the shortest possible time. It is important to observe safety precautions while using the solution. The process of preparing, as well as to dry completely, but allocates a sufficient amount of harmful substances, impact on human health.

To the finished mixture may be easily mixed with water and the addition of necessary components, used a powerful electric drill. It is unlikely to succeed on their own to get a quality solution. Coffee is the most optimal method.

If the layer of self-leveling floor has been broken, or there is a need to give it a smooth surface, handy sander. true, it is also necessary to be able to use. subsequently,, that has been removed, any dust and dirt after work, It requires building cleaner.

self-leveling floor It can be filled again or just performed an additional topcoat. In this way, It happens installation process again. To the solution was well razravnen throughout the area, using a notched trowel. It entire prepared mixture align over the entire surface, so that she can more evenly distributed. The optimum width is 60-100 cm. teeth also should choose correctly, to be equal to half of the self-leveling floor screed thickness.

Like the spatula has a tool, as the Wipers. The main difference is, the width of the teeth and their length independently regulated performer. Since it can be performed even when a very thin layer of a self-leveling floor 2-3 mm. During repair work no vibration of the tool should not be. Should be treated properly when selected.

When mixing the solution for performing floor installation, can form bubbles. That should get rid of them after pouring, Why is aeration roller. It is used to setting of the solution on the entire surface. This must be done for 40 minutes. Properly should choose spikes length, so as not to damage the fill.

Situations may arise restore a large area of the room. Then the need to perform the installation of beacons and use the rule for leveling solution. Its average length is typically 150-170 cm.

After the purchase of any new instrument should be placed in a solvent in the hours 3-4. This will remove the preservative grease, which is in the process of restoration of self-leveling floor can create additional defects in contact with the base.

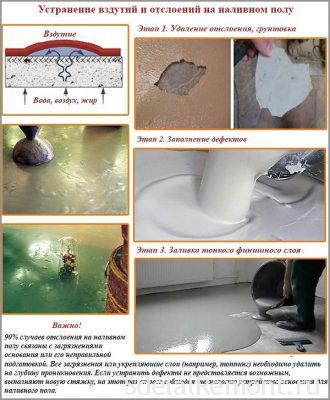

detachment

When this process occurs, people say that, that raised the floors. Swelling can be in a certain place or over the entire area. For this reason there are basic:

- The base for the fill has been prepared not qualitatively. There was no priming, purification from dirt and dust. Adhesion of the mixture to the surface has low.

- Substrate humidity, which is filled self-leveling floor. It is necessary to wait for drying, eg, concrete screed completely, and only then perform the installation.

Many people believe, that a large amount of water only help to prepare a solution to be distributed over the area in a room. Some even fills the puddles (Vod and primer). In consequence, this leads to the appearance of defects.

- The surface under the fill has a weak strength.

It's easy to identify the areas of peeling - knock on Self-leveling floor semi subject. Hollow sound indicates need for repair. If you do not pay attention, then over time the floor in these areas will begin to crack. Minor damage removed with a chisel or impingement plate, after which the solution used special reconstruction, as well as of grinding. Do not be amiss at the edges (under a layer of self-leveling floor) run water glass. This new solution, and the old will be well-knit.

there are cases, that the floor has such defects in almost every room. It will be easier in this embodiment to expose the base self-leveling floor and thoroughly investigate it to the error. After these events fill repeats from the beginning.

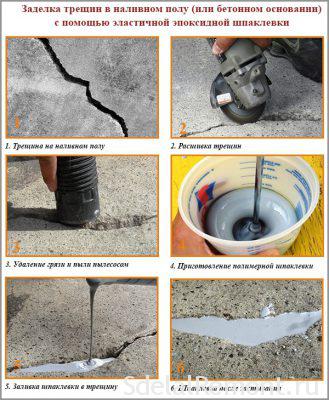

removal of cracks

Cracks in the floor of the filling - the most common defect. We can say with confidence, that mount technology have not been performed or it does not know. Minor one millimeter, no role to play, but larger defects should be immediately removed. Work will be a bit special and the experience necessary not.

Cracks appeared necessary to expand, clean and treat the reinforcement Primer. Once the surface is dry, it is filled with special repair concrete, then grind in.

Cracks in the floor of the filling may appear periodically, even after their elimination. This indicates a drawdown grouted. Do not be amiss to check the basis for defects: floor slab "walks", the formation of shrinkage cracks in it. As such, the repair take much more time and money. Otherwise, get a perfect self-leveling floor will not be possible. Local elimination of cracks on the surface will have no effect.

A large number of cracks can not be repaired. It is necessary to turn to specialists, which can be dismantled and replaced by self-leveling floor screed concrete, if the reason for it.

Depreciation and loss of quality

Over time, the operation of self-leveling floor begins to lose its original appearance and quality. In this case, it is not necessary to spend money especially, but enough to make fill the new topcoat, selecting a suitable option for combination with the design of. Among the main causes of this defect - permanent load. In addition, these areas may not appear on all area, but only in certain places. To get a better quality, better will generally eliminate the old layer of self-leveling floor, and pour a new one instead.

Prior to the application of new polymers, the old base should be carefully cleaned of possible irregularities and defects. This will get the best result. That is how I perform this update at the interior surface of the changing room. Layer screed obtained insignificant and has no effect on the distance from the floor to the ceiling in the room.

Buhtenie

Some surface defects inlet floor can be combined with each other. After that, both filled, floor cracked in some places. It may even be supplemented by peeling. This phenomenon is called "buhtenie". Besides, that cracked self-leveling floor, he began to flake off, resulting in creaking. This may be a few main reasons:

- moisture surface, which runs pouring self-leveling floor, is more than 4%.

- The surface was not prepared to work (there is dust, mud). Qualitative Adhesion offline.

- No sealing layer based on. Even if any crack can be, are transmitted finished solution inlet floor.

To get rid of such negative phenomena, to delete the site, which is moved away from the base, then thoroughly cleaned of possible dust and dirt. Optionally, wet wiping portion. Next in 2-3 a primer layer applied. Will only produce self-leveling pouring the mixture in one layer to the entire surface.

For best results,, additionally poured topcoat throughout this portion.

Bubbles and craters

For such a defect is preceded by the following::

- Poor kneading solution (often with their own performance or the use of large speed drill). All possible bubbles in the drying process will move to the top of the surface. Once they are dry, in their place will be the craters, distention.

- High humidity in the performance of work (more 60%) and the room temperature was lower +5 degrees.

- Performance the inlet floor thickness, not in accordance with the minimum standards set by the manufacturer.

- Contact of the oil droplets in solution, who did not have time to harden.

- A mixture of poor quality is used in the work.

Bubbles can be easily avoided, if after pouring walk aerator roller. He will remove them and not allow subsequent defects appear on the surface of the self-leveling floor. But if you already have difficulties, they should be handle.

A small number of craters and size can be eliminated by "burying" them with a solution of. When large areas, it is easier and more profitable to produce fill the new screed layer. If the crack self-leveling floor, or there are other defects, you should immediately seek ways, to get rid of it.

Pomutnenye

work is finished, surface self-leveling floor has dried, but there is a clouding of a whitish hue. This degrades the quality of the mixture fine, It appears dull, weak distinctiveness. Any images or pictures will not look natural. true, with all operating characteristics remain the same. Eliminating such a defect occurs on the polyurethane, or epoxy floors. Identify the following main reasons:

- On pouring hit fat droplets, other aggressive compositions is.

- Mixture used for poorly implicated.

- A large amount of water added.

- Stir the components are not on the proportions.

We'll have to try very hard, to carry out repairs to the quality of self-leveling floor. Optimal - make another finishing layer. It is very important to pay attention to casting technology. All the proportions and recommendations will be reflected in the instructions.

Chips and gouges

When exposed to a sharp or blunt objects with enough weight on the floor surface of the filler, may appear not only to crack after laying floors, but chipped. May break away portions together with a polymeric composition and concrete base. Everything will depend on the degree of exposure. The very process of resurfacing will take away a lot of time and effort. It should make cleanup, then apply a coat of primer and a filler if necessary. In the end will produce the finished casting solution layer.

When there is no possibility of self-repair Self-leveling floors in the apartment, it is best to contact the experts. They will be able to do everything efficiently and in the shortest possible time.

The saving of the floor surface after casting promotes savings. But that no one is safe and potholes may occur at any time and under any circumstances, when he does not expect.

recovery Features

If cracked self-leveling floor, you must take all comprehensive measures, to eliminate this defect. Filling may be performed over old layer, or with a separate portion. In any case, need to sweep the surface, in the right places - a primer, completely dry before pouring.

Epoxies mixtures require repair cracks self-leveling floor using similar formulations (epoxy resins).

Study all the successive stages will be better on video. All these details will help to find the original source, why self-leveling floor is cracked after casting. Even in such a situation to self-repairs, should calculate the forces and capabilities. When this is nothing, then the direct road to the construction company, engaged in the given direction. Paying the amount for the service, you will be given is really the desired result.