- Lightweight aggregate blocks in construction

- Lightweight aggregate blocks analogs compete with

- What are the advantages keramsit

- Types blocks LECA

- Mounting partitions keramzitoblokov

- Solution keramsit

- Substrate preparation

- How to put keramzitobloki

- Perevyazka

- Doorway

- End of building walls

- Pazogrebnevye wall panels

Today there is a wide variety of materials, from which we can build a long-lasting and high-quality partitions. Each of them has its advantages and disadvantages, what, naturally, It affects the comfort of living inside the structure, built out of it. The cheapest way - is the construction of partitions of lightweight aggregate concrete blocks, while their cost is much less than the foam blocks and gipsoblokom.

The photo presents the most common materials, of which can produce masonry elements of virtually any dimensions, at the same time they will have a much lower weight, than the same brick. Besides using the room units is greatly reduced flow of solution to their laying. Today, one of the most popular materials, that meet all modern requirements of sustainability, and in terms of efficiency is a block wall keramsit.

Lightweight aggregate blocks in construction

Lightweight aggregate blocks - the modern material for construction. Its use reduces many times the weight of buildings. Such blocks are used as partitions and as separate wall.

Compared with gipsoblokom and penobdokom, partition value of keramzitnuh blocks cheaper.

Blocks of expanded clay - an indispensable material consists of concrete in the construction of residential domov.Bloki, to which is added keramzit, which makes the material very easy. Expanded clay - a porous granules, due to which blocks have many useful properties. for example, they prevent the penetration of moisture, and are protected from the noise.

Expanded clay is an excellent insulator, and thus it is considered to be environmentally friendly material. Expanded, aka "KERAMOS", obtained by firing clay. rotating special furnaces are used for its manufacturing, where as a result of rapid and powerful firing obtained foam pieces, which does not exceed the size of 5-40 mm. Keramhit not afraid of fire and sinks in water.

Tested over the years and highly resistant to rot and expanded clay caking. Lightweight aggregate blocks absorb moisture only 15 percent. experts note, it is a very high rate. Blocks are also insulated from external noise and have a high throughput capacity pair.

Expanded clay - a natural material (clay), therefore lightweight aggregate blocks are considered environmentally friendly material. In buildings from lightweight aggregate concrete blocks easy to breathe and humidity incorrect. Due to environmental components, they are called "bioblokami". In European countries, blocks of expanded clay have already proved themselves to be on the positive side. In Russia, for the last 10 years many customers have also appreciated the use of such units. Because the blocks are characterized by ease, retain heat and protect from the cold.

Lightweight aggregate blocks are produced in several ways. The vibratory casting process can generate the desired color and texture blocks. There peskotsementnye lightweight aggregate and "stuffing" for concrete blocks. Modern equipment it is produced by vibro. Due voids premises protected against low temperatures. A lining blocks do not require additional finishing hereinafter, although the weight of the blocks are lined with slightly heavier due to the use of artificial stone. So that the construction of such walls is comfortable and allows you to save money and construction time.

Lightweight aggregate blocks produced by specialized firms in a fairly wide range. Buyers are offered one-, bi-, quadrilateral blocks. Also in the construction of corner blocks may be required, which are represented in many variations.

Lightweight aggregate blocks - a guarantee of rapid construction. In general, the new technology allows 2 times to reduce the time for the construction of structures. Compared to brick, keramsit unit replaces the standard size 5-7 conventional bricks and has a 2,5 times less weight. cement costs for this technology are reduced too many times. And thanks to the textured units do not require additional cladding buildings. Variants of colors can be very different, from light to dark or dark blocks - on customer choice, that meets the individual needs of each customer.

Lightweight aggregate blocks analogs compete with

for example, they are similar in many respects in structure to the ceramic blocks, but due to the profiled ends are easily connected to each other. Blocks from keramsit thickness - no more 36 cm, which makes them indispensable in the construction of single-layer walls. A smaller thickness when they can easily be used for the construction of external walls.

if there is a threat of damage of the material and its insulating characteristics? Answer - No, solution misses the embedded block due to the holes with the one side.

What are the advantages keramsit

Claydite is the most easily accessible material today. You can buy ready-made individual products or make your own. To do this will require a vibration table for filling quality. This makes it possible to produce masonry materials directly to the construction site. But in order to save time and money, many prefer to buy ready-made products from trusted companies. so, what are the advantages of the material, and what he has characteristics?

Wall of lightweight aggregate concrete blocks gives a very warm and fairly soundproof. This property it possesses porosity due main filler block and manufacturing technology. The main component is the granular expanded clay. It is the calcined clay slag, filled with air bubbles. The presence of such a large number of bubbles indicates the excellent thermal insulation properties, as well as light weight expanded clay.

Depending on claydite grain can change their characteristics. Smaller pellets are used to make a more durable concrete. It is used for the production of foundation blocks or casting it in place. Also because it is possible to build load-bearing walls and structures, but the insulating properties of such material is lower compared to large beads.

Load-bearing walls of concrete at low-rise building can be constructed as a solid block of, and from the hollow. But in the second case they turn out a lot of heat due to additional in several rows of the air cushion.

Types blocks LECA

so, consider, what types of expanded clay concrete blocks used in construction today. Ease of production technology allows to produce blocks of various shapes and sizes:

- direct;

- g-shaped;

- pazogrebnevye;

- simple;

- jumper;

- crossbeam;

- full-bodied units;

- hollow and even reinforced concrete floors.

The nomenclature of products is very large and able to fill any needs in the construction of absolutely different buildings.

The photo below shows the most common building blocks for partitions.

Specifications keramsit

| Property | beats. amended. | Value |

| Thermal conductivity | Vt / m Town | 0,15-0,45 |

| Volume weight | kg / m3 | 700-1500 |

| Strength | kg / cm2 | 25-150 |

| Vodopohloschenye | % | 50 |

| Shrinkage | % | 0 |

| The duration of the cooling wall | time | 75-90 |

| Number of cycles of freezing | cycles | 50 |

Based on the table shows, that its parameters lightweight aggregate blocks similar to the silicate and can be used as an alternative to it.

Important to remember, that the construction in any case can not be combined materials or alternate them, because it can lead to cracking of the wall at the junction of the ground due to the difference of expansion options on heating.

Mounting partitions keramzitoblokov

so, The modern technology of masonry keramzitoblokov and erection of these partitions.

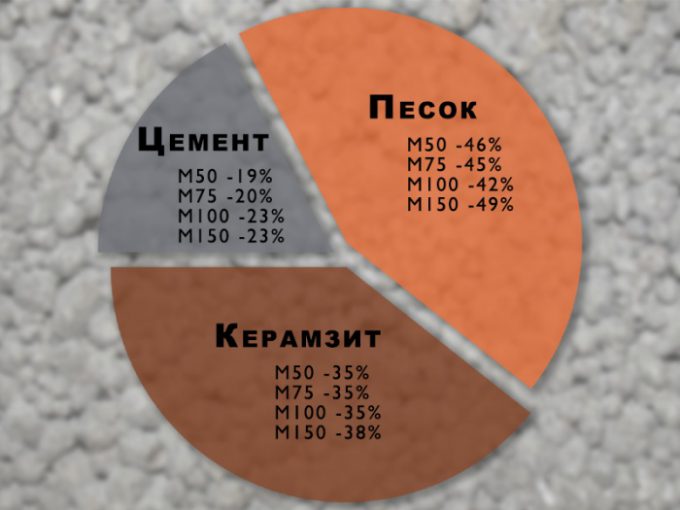

Solution keramsit

But we must first understand, a solution should be used for the construction of. Today there are several consumables, which can be used for the construction of partition walls:

- The cement-sand mortar. It is possible to prepare yourself, For this purpose, the ratio 1:3 is added to the cement in the sand and thoroughly mixed, after water is added. For plasticity to the mix, you can add lye or any industrial plasticizer. It's important to sift the sand kneading on a small sieve. Looking ahead, briefly consider, how laying blocks on solution. In such a case it is necessary to make a thicker layer of adhesive to better and more durable septum, but then there are difficulties with the design geometry.

-

Types of adhesive mixtures second, the most common because of the speed and convenience, It is the glue. The factory mix may be acquired as it, sold under the name of "adhesive for masonry walls of aerocrete», but you can also apply the mixture for laying tiles. The adhesive has the same properties and functions has not smaller adhesive. to understand, like putting glue on keramzitobloki, enough to see the attached video at end of article.

Substrate preparation

About tom, like putting keramzitobloki, photos and information below will help you understand the process, but first you need to prepare the base. For this installation site should be cleaned of old mortar, align and pave the waterproofing layer. As it may be any material intended for this. Align floor surface can be using a semi-dry screeds.

To obtain high-quality partitions it is necessary to build on pre-striping or use level. The thickness of the wall blocks can be from 10 cm 20 cm depending on the need, and they can be either full-bodied, and hollow.

It is important to remember that, that partitions in apartments or private homes with concrete floors to be built from only hollow, because their weight is considerably lower than, respectively, and the load will be less overlap.

How to put keramzitobloki

The first number is leveling, therefore the amount of mortar or adhesive depends on the requirements planarizing. To control the overall geometry of the entire partition should pull cord, and to control the vertical surface and significantly accelerate installation, it is recommended to use the guide bars. The video clearly shows, they are attached to one side of the partition on the level, and it eliminates the possibility of dam.

Today on sale there are not only strictly rectangular blocks, as well as pazogrebnevye. Due to the presence of grooves and ridge ensures reliable fixation between a, and thus the quality of the whole structure geometry. Expanded clay walls pazogrebnevye today are very popular in the first place because of the convenience and high speed of installation.

In the attached video represented the most common masonry walls of gypsum partition blocks. Here you can trace all the details of the installation and possible nuances at work.

Laying keramzitoblokov for interior walls is a fairly easy process, because the weight of the blocks is very small, and to work with glue - just a pleasure. But still worth it to see a video tutorial and fix some of the skills in theory.

Perevyazka

After laying the first row of possible to start installation of the second. It is important to observe bandaging to achieve the desired structural strength. Exercise this should be offset at least, than ½ lower block.

But it is also necessary to carry out the dressing and with bearing walls on the perimeter of the building. For this purpose in the wall on the upper edge of the block level drilled hole, then invest in which armature together with a solution of. Laying gypsum partition blocks greatly facilitated by the existing upper groove, it is necessary to just put a bandage, and if you use solid block, you will have to use the grinder to cut a small groove on the valve length. Expanded clay - enough solid material (baked clay), therefore it is necessary to cut only a special stone. it, perhaps, the only drawback.

Pazogrebnevye interior walls using hollow keramzitoblokov will be an excellent opportunity to hide the ventilation channels of communication. by the way, for their construction are commercially available special prefabricated blocks with a square cross-section of emptiness.

Besides dressing with load-bearing walls, installation of partition blocks of expanded clay should be carried out with simultaneous fastening to the floor, If waterproofing was packed. This can be done by perforated plates and anchors. During the construction of partition walls on a concrete base, without the support bandage to the floor, you can not do.

Doorway

Installation of partitions of gypsum partition blocks necessarily includes door or window openings, arches and niches. A large variety of sizes of lightweight aggregate concrete blocks enables you to create absolutely any designs. But how does the doorway?

This requires strengthening the extreme blocks. If you are using to do this is not necessarily full-bodied. Last block section is filled with a solution of, then opening stacked metal bridge.

Hollow blocks are commercially available ready-jumper, which lie under the unit and perfectly hidden in its structure. Partition blocks of lightweight aggregate concrete blocks should always be strengthened within, for this purpose in existing slots stacked thick wire or armature, thus creating a reinforced ring around the perimeter.

End of building walls

The partition of pazogrebnevyh expanded clay blocks must not be built to the ceiling. It is necessary to leave the airspace 1-1,5 cm, it should be filled with foam. This eliminates the chance of damage to the walls due to the vibration of the ceiling.

Pazogrebnevye wall panels

The large-scale construction pazogrebnevye panel for partitions used today. This not only allows you to significantly speed up the process of building, but also to save consumption of adhesive mixture. But in the construction of such walls necessarily need the help of strangers. If in the case of small masonry all the work he could perform a builder, then the construction of the partition of gypsum partition panels require an entire team of associates.

Installation of partitions of gypsum partition panels allows for less time to reach high volumes of work, the quality remains high partitions. One panel can replace up 20 blocks of medium size. But they have a standard height 2,5 m, suggesting the need to adhere to these parameters.

An important feature of the partition of gypsum partition panels is its longitudinal strength and the presence of special channels for laying of all necessary communications.