Elegant wall panels - excellent interior decoration. They are undemanding to operating conditions, simple and cheap to maintain. Panel made from different materials - plastic, wood, Fibreboard, PVC, whereby different properties and appearance. With this in mind,, Decorating the walls with plastic panels is one of the easiest, cheapest and most effective ways to arrange the room so, as you want.

Varieties of wall panels

finishes

Depending on the form, distinguished panel of these varieties:

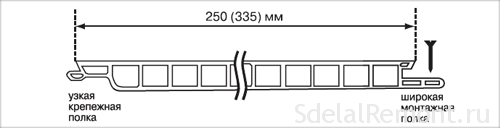

• Pinion splicers - are oblong tablets, made of wood, DSP, PVC, LCP or MDF. These panels for interior walls have a length of 240 to 370 centimeters, width of 12,5 to 30 centimeters and a thickness - from 0,8 to 1,2 cm. For connecting with one another the panels have recesses and pins. Permissible lining assembly in the horizontal and vertical orientation;

• Matched tiling - are squares with a side length of from 30 to 98 centimeters. Such panel wall perfect for creating mosaics, because each of them has its own color and texture. Material coatings - MDF, Fibreboard, PVC and chipboard. For compounds of plates used and the insertion slots;

• sheet - better than the others proved themselves in the decoration of the walls of large area. Dimensions of the sides may vary from 122 to 244 centimeters with a thickness of 0,3 to 0,6 cm. Unlike other materials, sheet panels on the wall made only of wood or resin-impregnated fiberboard.

fastening plates methods differ. So, rack inlaid panels for walls are fixed to the furring, tile - using clamps or adhesive. The glue used for fastening sheet metal panels, and coating the joints between the elements camouflage moldings. Independently make installation of PVC Ceiling? Watch Video monitored and read here.

Classical solutions trim panels

When a trim plastic panels with their own hands, you need to consider not only the type of cover elements, but also the material of their manufacture.

Considered reliable wood products, they are made out of wood, like alder, maple, oak or cedar.

Sometimes a finishing wax coating, through which it can be operated in a high humidity level smokers. Since the wooden building panels for walls environmentally, they are recommended to be used in residential areas.

popular products, made of MDF - material, consisting of woody plant fibers. They also are safe for human health, resistant to moisture, but become useless in direct contact with water. In turn, made of chipboard cladding panels for interior walls in appearance and quality of such wood. This is because the, that represents a pressed particleboard wood waste production. The disadvantage of this material - poor tolerance of sudden changes of temperature and humidity.

panels, made of MDF, characterized by increased resistance to virtually any environmental factors. Fiberboards are obtained by invoking a method of dry pressing, therefore, moisture and mechanical stress they are not afraid. It is recommended to finish the walls with panels of MDF type of the premises, where conventional materials are short-lived or ineffective.

All of these types of panels are recommended for use in residential areas. With proper care, their life will be longer 10 years old. Especially long service life have a wooden wall panels for walls: if they are made of quality wood, it will keep the original appearance for several decades.

Panels of new materials

Made of known panel gipsovinila reliability and durability. The material of manufacture - modification plasterboard, and it is similar in properties. On the best side we showed itself and the plastic wall panels for interior decoration, are not demanding operating conditions and are easy to maintain.

Novelties in the market of building materials are glass panels-and 3D-panel. The former are intended for application to the surface of the walls of photographic images, the latter have unusual texture relief with hypertrophied. Made 3D-panel of all the materials listed above, and aluminum.

It allowed with plastic panels wall decoration in residential, commercial and public establishments. Often, this coating is used in schools and kindergartens, because it is considered environmentally friendly. In turn, glass panels as safe, like plastic, and able to withstand substantial mechanical loads, but are less common, because the more expensive. The same applies to the increasingly popular 3D-panels.

Installation of wall panels

For attaching panels to the wall surface will need the following tools:

• Pad-saw;

• electric drill;

• Screwdriver or screwdriver;

• hacksaw or metal-cutting shears;

• hammer;

• building level;

• roulette;

Finishing is carried out wall panels only after, How to process the surface leveled and cleaned of dust, paint or wallpaper. Start work you need to measure the area, which takes cover. At this time, let polezhat panel on the inside - that the material adapted to the room temperature, It requires more than half an hour. Protective film from the panel, do not remove: do it, When the installation is complete. The film will avoid accidental damage.

If you plan to install the dial pad, be manufactured lathing. It is a wooden slats or metal strap, spacing of 30-40 centimeters. rails direction depends on, how wood plastic panels for interior walls will be attached: furring elements and coatings must be perpendicular to each other.

For tile and sheet panels do not need a crate. It is also possible to do without it, if the surface being treated is made of a flexible material: then wall decoration wall panels is carried out using self-tapping screws, clamps or brackets, drives a special stapler.

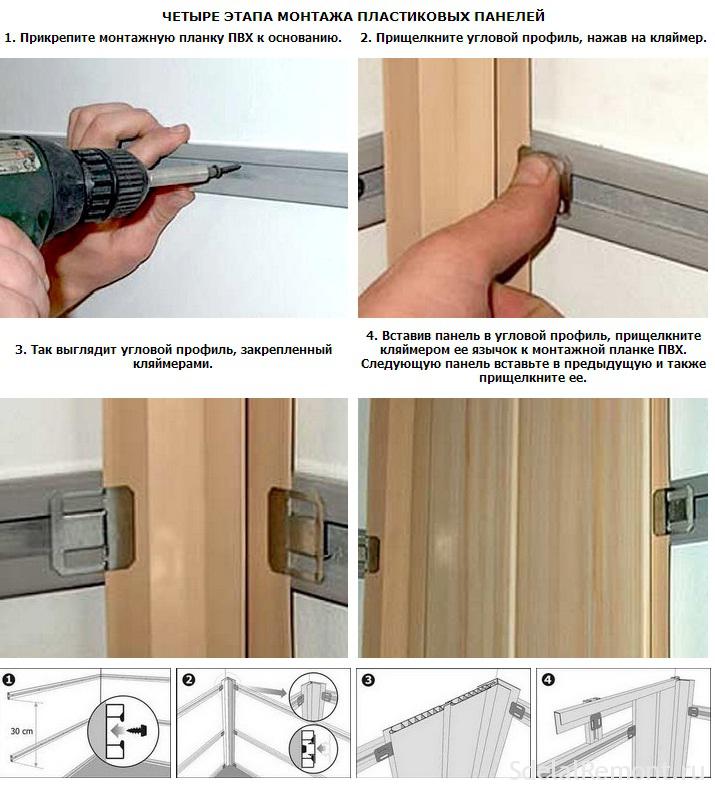

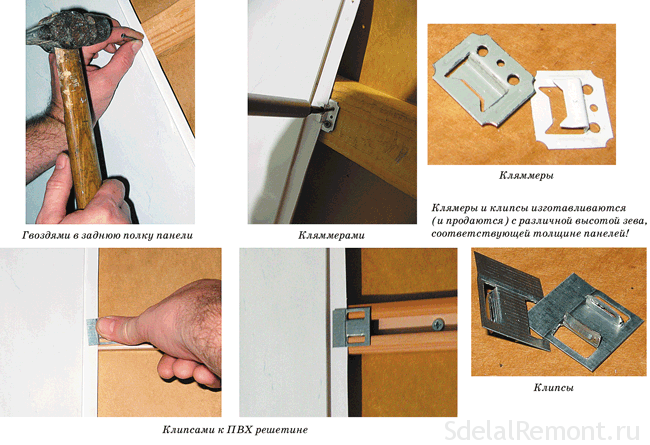

Proceed directly to the installation plates recommended after, as it will be attached fittings - external and internal corners, The final element, ceiling Molding. Each type-setting panel for the walls has on the one hand mounting shelf, on the other - the mounting. Installation with horizontal orientation of the panels is made from the floor to the ceiling attachment flange down. On the side panel mounting flange is fixed with screws, brackets, nails or glue. Then dock mounting shelf panel next to it. Elements lining customize as tightly as possible to each other.

Likewise attached sheet plastic panels for interior walls: plates also have grooves, with which are joined to each other. During installation, the final panel, the final number, You need to insert it by force between the fittings and the last panel. Sometimes it is necessary to resize the sheet with scissors or hacksaw.

Tell us how to stick on the wall in the kitchen fiberboard panel (not to be confused MDF) size large 2m40sm x 1m20sm? Wall almost flat (not ideal) plastering. I will be very grateful. I have for instance the panel with decorative cover “Crimea stone”.

First of all, to protect themselves recommend to consider additional mounting system. If possible, pass-through, if not then hidden on the back side, as a mirror. Since the sheet has a large format. Ruler liquid nails large, well kept siliconized adhesive Bison. Modern adhesives can withstand great load. It is very important to prepare the base of the wall so it was not dusty and not zhirnee.Vozmozhno giving further paint. According to the experience say that stuck large size mirrors and no problems.

Thank you for your response! most inclined to silicone adhesives because they have good adhesion. But there is the experience of multiple – many claim it to bison, I will not create a bad reputation, because, that is not my experience. As I understand the huge sheet- a large area and must have progress when the temperature difference, then most probably, or as you said siliconized liquid nails or silicone sealants. confused plaster (not plaster) here you need good penetration – adhesion. Thanks you.

Thank you for such a detailed instruction! I would like to share with you and your readers a video instruction for MDF panels – https://www.youtube.com/watch?v = ta3h0J0anpI

We filmed at the factory, panel also their. just clip 7 minutes. I hope, It will be useful.