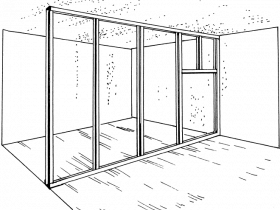

Making drywall is one way to cheaply and quickly isolate the space, make a separate room or hide elements of plumbing and ventilation systems in the middle of the room. Creating plasterboard partitions requires some effort, but it will not require heavy physical work.

design of partitions

baffle design consists of three main elements:

Frame plasterboard walls can be made of a metal profile, that is the most common. Wood occurs most rarely because of its drying, and whereby the entire structure -deformations. and combine. The main frame is made of metal profile, and the pieces of wood are invested to create the possibility to attach the wall hard interior elements, household appliances and other components.

Manufacturing begins with the selection of partitions material.

The advantages of using metal sheets?

Metal profiles can be of any size, which gives the opportunity to build from it challenging transitions and every niche. In addition, it is easy enough material, structure from which is obtained a strong and durable. The main advantage is that the metal profile, that its operation, in the manufacture of curved structures can bend.

Decide on the type of material used must be addressed the following issues:

- What shape should be design?

- If you invested warm - or soundproofing?

- Whether it will conceal pipe, ventilation passages, etc.?

Pre-project drew partitions on a sheet of paper. We decided on the location of the door, niches and other. If the partition will have to hide elements of sanitary ware, electrical wiring or something else, the wall must be made of a thick airfoil (100 mm).

Next, you need to start drawing of markings on the walls and floor. To do this, use a plumb bob and string construction. With the help of the level of the floor layout is transferred to the wall, and using a plumb line on the ceiling.

Manufacturing walls of plasterboard with their hands is performed using two types of profiles:

- YOUR (guide).

- CW (rack mountable).

Respectively, rack structure is used to perform vertical elements, a guide used in the horizontal part of the construction. In this case the guide profile can be of the following dimensions: 40x50, 40h75, 40x100 mm. Rack - 50x50, 50h75, 50x100 mm.

Of fasteners and hardware components required for the construction of walls following fastening components:

- Screws for fastening the metal profile between a. They have, in contrast to wood screws smaller thread pitch, allowing them to clamp the metal sheet is much stronger and hats have flat bottom, and the top is slightly spherical. Instead, you can use rivets. Ideal for attaching to use Prosekatel Profile .

- Screws for metal sheets for fixing plasterboard to profile. Usually they are black also with fine thread, but a wedge cap. This allows him to dive in a little piece of cardboard. The calculator will help calculate the right amount of self-tapping screws.

- Dowel-nails. Self in a plastic cage, It is used to attach to the wall metal sheets, if it is made of bricks, CBC blocks, monolith.

If the walls are made of wood, here to help, respectively, screws for wood. Their length is chosen based on the weight of the future partition and apply it to the load.

Mounting design

Having dealt with the types of materials and having bought all the necessary accessory, possible to start mounting the first structural elements.

The first thing you want to attach to the floor guide profile. If the floor will rise in the future, it is necessary to leave room for the doors. The distance is chosen based on the width of the box with a small margin in 2 cm along the edges to fill voids with foam. It not only fasten the door frame, but will also provide cushioning door, and not the entire wall.

The guide profile is fixed to the side walls and the ceiling with fixing step is not more 50 cm. If necessary, it can be reduced, but it is recommended that.

Types of partitions, depending on the design:

- single layer;

- bilayer.

The first type is used in a lightweight partition, wherein no additional strength and soundproofing. It uses only one layer of drywall on both sides. The second type is a more massive structure, respectively,, and heavier due to the attachment of two layers of sheets of drywall on both sides.

Once we decided on the type of partition, thick and its attached guide profile, you must start the installation of strut members. They are installed in the guide trays and exposed vertically. When this rack is cut, taking into account the distance from the lower profile to the upper net 1 cm. Near the doorway is recommended to put wooden blocks on the profile thickness, and fixed it with screws for wood. The recommended distance between the vertical elements of structures made of plasterboard walls is 60 cm. it can be reduced if necessary, but not to increase.

There are two profile mounting technology. first, called American, It is the location of the slot to the far wall. The second technology, which was developed by German builders, It consists in a groove arrangement in the mounting direction.

Methods for mounting rails and rack-mount profiles with their own hands

There are several ways of fixing the guide and rack elements:

- T-connection.

- The compound of structural components by cross spider.

Types of fasteners metal profile

A simple T-junction is in the notch of the two lateral sides formed by folding profile and lobes on 900 apart. They will then be carried via the two fastening elements. This type of compound can be used as a cross, and in the end structural elements.

The second type of connection is used predominantly in cross docking profiles. The fixing member is a plate with a plurality of cross-shaped lobes and perforations, intended to simplify the construction of the installation. It is also commercially available, and many other accessories for a variety of connection options and connections, even at an angle 450.

Once the design is ready, you can start fasteners GCR.

If the partition should be easy, then coated with a single layer of paperboard, otherwise the second layer is attached directly via the first into the metal profile. At this distance the first sheet fastener can be increased 50 to 75 cm. The second layer is secured within the recommended distance, no more 50 cm. Laying sheets should be carried out with 50% overlapping the top of the lower.

After dividing wall on one side it is completely covered with plasterboard, you must begin to heat- and sound. As it can be foam, mineral wool. The density of the pile depends on the degree of internal space noise reduction wall. After the construction of communications, wiring and plumbing, laying sound insulator may be attempting to install the FCL with the second side of the partition on the same principle.

Finishing drywall partitions

Finish all of drywall constructions carried out on a single technology:

- If they stick wallpaper, it is sufficient reinforcing mesh glue joints of gypsum coating and spatula to cover the dimples, formed at tightening screws.

- If the wall will be painted, proshpaklevat then necessary across the partition surface with subsequent stripping and primer.

Making drywall is an excellent option, because in the end always turns out perfectly flat and smooth wall.

online Calculator, calculation of material for the walls of plasterboard