When there is a concrete surface with irregularities and other defects, it's worth thinking about, to produce alignment using plywood. But it is very important to know the circumstances, where it may be applied active material, as well as the necessary tool set. After all, for finishing flooring or floor covering, however it was not, base should correspond to the level and to be perfectly flat. If this be neglected, the life of the coating reduced at times.

types of alignment

There are various options for a flat surface using plywood. All will depend on the base directly (wood, concrete), as well as device capabilities lag, over which the fixing plates.

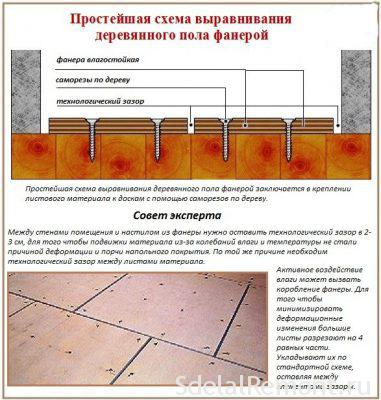

If you have a wooden base, the plywood is sufficient to fasten with screws to the surface. But it is very important to carry out a set of preparatory measures and explore having a hardwood floor. The very thickness of the sheets will have the corresponding figures. Usually it is at least 10 mm.

For perfect alignment is perfect on the floor joists. In the following can be made entirely of any flooring coating floor. This can be not only, tile, laminate, parquet, but the carpet, linoleum, etc..

Which option to choose for the full alignment of the base, It will depend on the specific circumstances and wishes of the artist. In any case, the surface becomes smooth. Do not be amiss in this case to use the appropriate set of tools and additional materials.

recommendations

There are certain requirements and wishes during repair work subfloor. To get the perfect option, It should listen to the opinions of experts. There are the following items:

- It is best to use the birch plywood. It has the property, as environmental cleanliness.

This it is markedly different from such materials, like particleboard or fiberboard. Moreover, such a veneer is really a natural material. The health of residents of apartment did not suffer.

This it is markedly different from such materials, like particleboard or fiberboard. Moreover, such a veneer is really a natural material. The health of residents of apartment did not suffer. - Used sheets are excellent for this, if optimal thickness will be 10-12 mm. The strength of the floor surface and flatness in this case will be provided.

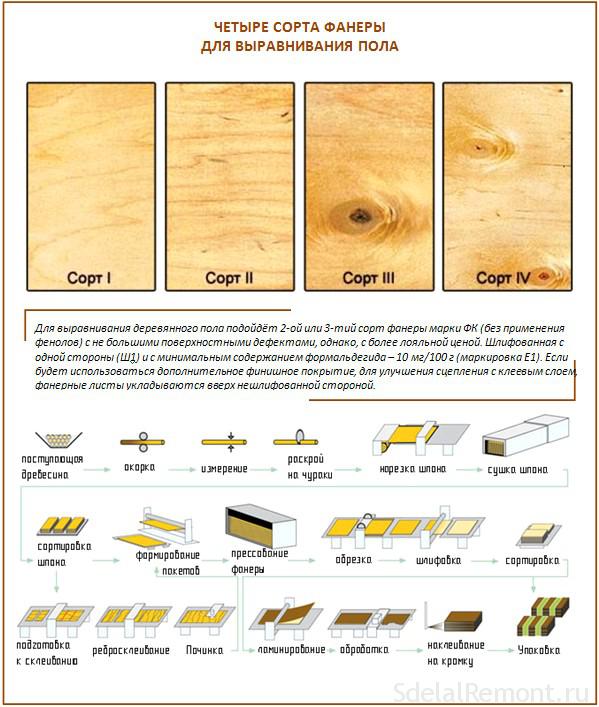

- There is no need to spend a lot of money and acquire high quality plywood. Even the most recent class sheets will contribute to obtaining a good result. Subsequently, all the same carried plywood flooring and finishing flooring their.

When choosing material for planarizing, should pay attention to what, that it has a quality, as the humidity. In this case, there will be problems with some level of humidity in the room. But if it's a bathroom or kitchen, then you should consider other options for alignment grounds.

Necessarily produce packing sheets in the Extension to the joints of each row were in the middle of the next row.

Advantages and disadvantages

When using plywood, it is necessary to determine the order, exactly what it has positive qualities of active material. This primarily concerns the, that all work can be done on their own without the involvement of construction brigades.  When this work is carried out in the shortest possible time without any extra costs. In the subsequent installation can be carried out completely any floor covering. The surface becomes perfectly smooth and strong.

When this work is carried out in the shortest possible time without any extra costs. In the subsequent installation can be carried out completely any floor covering. The surface becomes perfectly smooth and strong.

Any technology other than pros, It has and cons, about which we can not mention:

- If you depart from the technology of creating a flat surface using plywood, with the manifest buzz in the floor over time, and the effect of the "drum".

- Creaking appear in the event, if the quality of plywood is not suitable. It will also lead to, that the floor will start to creak and inconvenience.

preliminaries

When laying plywood concrete floor, should take maximum measures to bring the base to the necessary parameters. Concrete can have an increased moisture level. And this is just a negative impact on the state of sheets of plywood after installation. Consequently, should conduct a humidity level studies before starting work. If this rate will correspond to the norm, then you can proceed to the next stage of repair of the floor surface.

Moisture check may be performed improvised means. For this purpose the surface of polyethylene film is laid, the edges of which are pressed carefully to the substrate. If after three days, then it will have the inside condensate produced, it is best to postpone the operation for a while. The steps can be taken to reduce the humidity during this time, using various means.

There should be no problems with the, whether it is possible to align the plywood floor. This material is excellent for this purpose. But before the work should cover them with antiseptic, allowing in operation to protect sheets of high humidity and low temperatures. In addition, it will be possible to forget about the formation of mold on the surface or fungi.

The most affordable are plywood sheets 4th category. This variety has visible defects, but it is perfect for creating a flat surface. rough alignment It will be performed in compliance with all. If you want to have a final coating, the grade is chosen best quality.

according to the furring

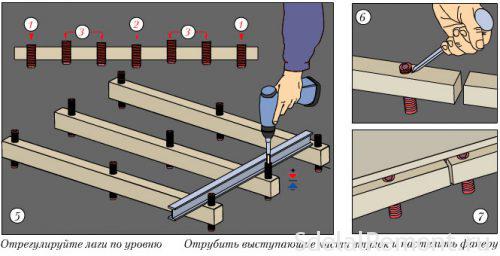

There are many ways to carry out under the plywood floor leveling. When the sheets are used, most often arranged lags, and to them are fixed elements. But there are two basic ways, how to get rid of the defects of the concrete floor surface:

- Apparatus tape supports.

- point of support.

In each case, there is a sequence of works, which will contribute to attain a perfectly flat floor.

Belt supports can not do without the transverse and longitudinal components. About the longitudinal can say, that they do not adhere to the walls. Must maintain a distance of approximately 30 mm, the need for expansion progress. used sheets, to align the floor under the plywood, influence the distance between joists. Typically, the distance is selected within 40-50 cm.

For this method, there is a sequence of actions, which include:

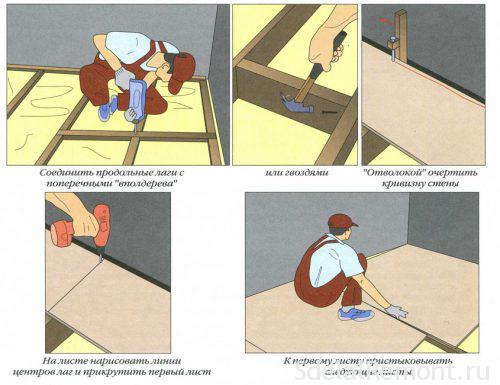

- Originally produced layout of plywood on the floor surface. In this case, it is not necessary to fix, just try, determining the required number of sheets. Should be observed checkerboard pattern arrangement of the material sheets.

- On sheets drawn with the installation location of the longitudinal members crates.

- Do not be amiss to number each sheet of plywood, so that in the future no problems with installation.

- According to the markings laid out on the floor joists. For a start they are fixed along the walls, and then between them. In even sliced veneer may come as a material.

- For floor leveling screws are screwed to the sheet lag. You can additionally use metal corners.

- According to the building regulations, should not enclose under lags if necessary raise the level of wood or metal wedges. Here the best option - to make a sand podsypku, or enclose roofing material.

- should fill insulation material to improve the quality plywood floor leveling all the voids between joists. The alternative - sawdust, mixed with PVA glue.

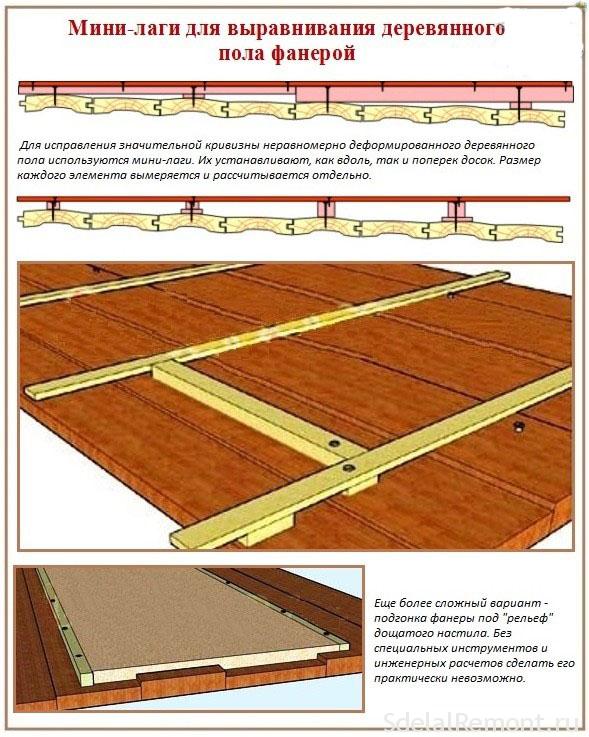

When there are significant differences in elevation in the room, you can use the alignment technology of concrete floor with plywood mini lags. But few people can independently handle the job. It is better to invite experts, who will be able to fulfill all quality.

Now back to the use of point of support. This option as supports along the perimeter of the room includes the use of OSB-plates, wood or plywood elements. Their height should correspond to the difference plywood thickness and level difference on the basis of. Since the reliability of such structures considerably smaller, it should increase the number of supports arranged.

We can not forget about the underground ventilation. The pre-marked points veneers after mounting holes drilled. They are well hidden decorative elements (grille).

no lag

This method is only suitable for wood base. This is the easiest option alignment floor using plywood. It is very important to choose the optimal thickness of plywood for use. If the width of the floorboards 200 mm, the material is selected as at least 100 mm. If the floorboards have a width greater 200 mm, and the plywood should be chosen with a minimum thickness of the sheet 200 mm. They also have a sequence of actions.

- Formation of the indentation on the wall. You should also remember about the temperature in the gap 30-70 mm. When changing the level of the material and the room humidity, It will not happen of its deformation.

- You can align the plywood floor, but the location of the plywood sheets must comply with masonry. The displacement must not be less than a quarter of the used sheet.

- In order to avoid problems, how to properly align the plywood floor, should distribute the mounting points. It affects the pitch between the high-altitude drops, that have been identified previously.

- All the fixing holes must be made previously, to subsequently cracked, did not occur along the length of material. From the edge, they are located at least 20 mm.

adjustable floor system

The use of glue

There are innovative ways of, how to align the concrete floor with plywood. One of them - mixture of glue application and sawdust. This kind of coupler, over which subsequently made stacking veneer sheets having a thickness in the range 5-8 mm. If this applies to wooden floor, then there is an economy of means. Though in this case it requires more time for installation. This is especially noticeable when a large difference between the heights of the subfloor.

The algorithm includes the steps of, which should start, as everywhere from the surface of the preparation for work. It should also be there to fill the base of the rack beacons, which are exhibited by the level of. All the space between them should be filled with a mixture prepared. Usually it has done a few layers of this "tie", but no more than two. The evenness of the adhesive should be checked for each application using the level.

After that, everything dries, you can start laying the plywood sheets. This will let you know about, how to align the floor in an apartment plywood.

Getting rid of the minor defects

plywood floor with their hands Leveling should be carried out in compliance with technology. In the preparatory phase are verified elevation changes and measures are being taken to create a horizontal level. In the presence of minor surface imperfections, there are certain methods to get rid of them, as well as the mounting features of plywood.

If the elevation changes make up 10 mm, the sheets can be fixed on the concrete floor immediately, without installing lag. But the thickness of the plywood in such a case should not be less than 18-20 mm.

For fixing the sheet on a concrete base with minor defects using dowels or adhesive mastic. Do not forget never about all kinds of preparatory measures. But the adhesive is applied to the concrete floor using a trowel with teeth. There should be no problems with the, which align with plywood floors. It must be thick to provide a solid foundation.

The use of plywood for floor leveling in the apartment allows even hide significant base defects, that reach 50 mm. In this case it will remain reliable if necessary in the future to produce flooring floor covering. For environmental cleanliness is better to use birch plywood, possessing besides all the necessary qualities of strength.