The basis for the flooring floor covering - floor screed. For its creation, every effort should be, to get a good result. The surface should be smooth without defects, to meet all the requirements. To work is necessary not only to prepare materials, instruments, but also to decide on the, What thickness of the concrete floor must be.

requirements

Selection of the concrete floor thickness affects the functions exhibited screed, so it is important determined by the height and the material for filling. This layer is required to generate not only the dynamic, but static strength, imparting a flat surface designs. The base should be as, that it was possible without problems lay the tiles, linoleum flooring or laminate installation. If the thickness of the concrete floor is correct, the load is evenly distributed over the entire area. This in turn will extend the service life of a base

Selection layer may vary depending on, whether you want to create on the surface of the slope. This is important for such premises, how predbanniki, Bathrooms, shower rooms. In any case the thickness should be such, to easily withstand not only on the distance, but placed on the surface of furniture. At the same time around the base of it must be equally dense. You must not occur chips, any defects such as cracks, emptiness inside.

Permitted maximum slope to a flat surface of a floor screed within 0.2%. Everything will depend on the room itself, where the screed is installed, as well as individual design elements. The same applies to the warm floor. Too small size layer will warm up quickly, but very quickly cool off, which will lead to unnecessary operation of the boiler. The thickness will be influenced primer, floor slab or other basis.

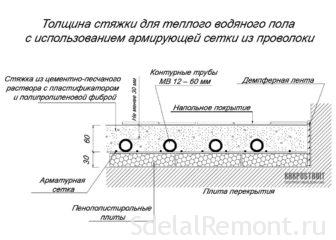

We can not forget about the fact, that under certain circumstances must arrange additional reinforcing layer. Most often it is a steel grid with a certain diameter elements. It will somewhat increase the limit layer of screed. But there are modern ways to perform reinforcement - the use of the fiberglass. It has even better qualities, giving a solution of plasticity, strength and ability to resist destruction, shrinkage and cracking.

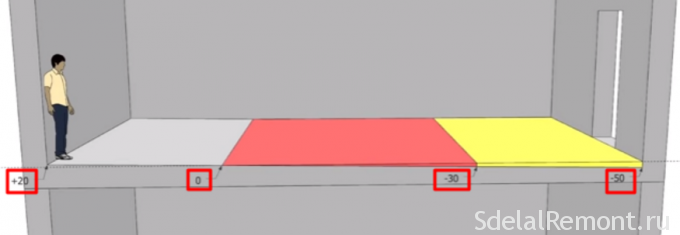

The worse the flatness of the base, the more screed thickness. After all, it is necessary to obtain a smooth surface with minimal performance grouted. In some areas will have to increase the thickness of, and in some cases make it less.

Selection of ties

Depending on the thickness, screed layers has the following.

- Roughing screed with the minimum thickness. all, probably, gets interesting, which one layer must be in this case. The most frequently used neveliruyuschie rough dry mixture with up to 20 mm. No reinforcements will not be required for this type of screed.

- subfloor height to 70 mm. There are already provided for the reinforcing elements in the form of elements or reinforcement steel mesh. Most often made of slurries or semi-dry screed technology.

- Maximum thickness, reaching to 150 mm. it is a monolith, within which the armature is also present. Its main field of application - the foundation of the house with a floor. I.e, Both functions are merged together.

When pouring concrete selected together with detritus, something about the minimum performance can be forgotten. Particular influence gravel fraction. When it is necessary to arrange a thin floor screed, work included in the self-leveling mix. The same applies to other types of mixtures, which are mainly used as topcoat device floor screed. The layer is obtained not only a thin, but even, able to be used as a decorative element.

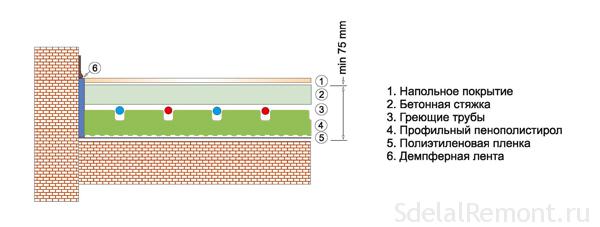

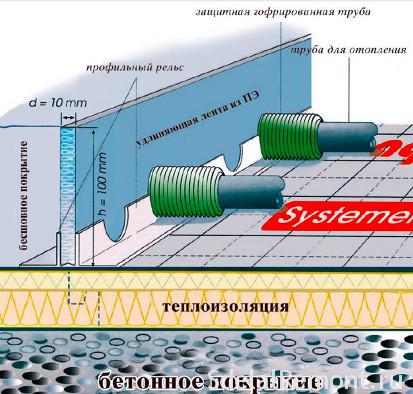

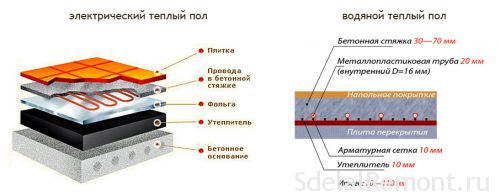

It should be a little bit on the warm floors. After all, everyone wants to know about, how many centimeters must be screed for underfloor heating. The solution should cover all parts of the system, possible cable and wiring. If the thickness of the pipe in the average of 25 mm, the total fill layer is usually taken in the range 50-70 mm. Greater thicknesses are not taken, as the floor heating will not function on the parameters. experts say, that over the heating elements is sufficient 40 solution mm. Otherwise, the system will be disrupted supply heat into the room and floor heating. The main mass of energy will be spent on the, to warm up the concrete itself.

It is worth noting, that a large thickness of the screed on warm floor lead to, it will begin to greatly expand when heated. Consequently, will suffer the wall in the room. This will eliminate the pasting of walls to fill the damper tape, able to compensate for fluctuations data.

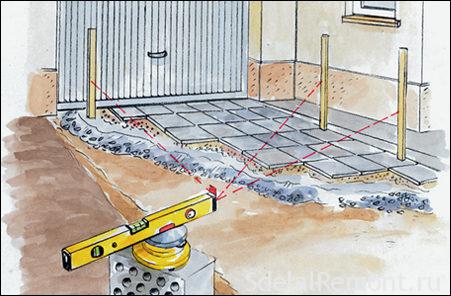

Determination of irregularities

Yourself at eye no one will determine, What are the bumps on the bottom for pouring floor screed. To do this, the easiest option - the use of a bar or a special level. Let's start with the bar.

bar size should be approximately a half meter. Walking them on a floor surface, Holes can be found existing between itself and the floor level. If a large number of them, or there are significant differences, you'll need to arrange the maximum thickness of the screed under floor heating. The new apartment at the old base is replaced by a new, screed is taken within 35-50 mm. We can not say that, that the quality of the base will be affected by the large thickness of the screed. This view is erroneous and needs clarification. After screed is only necessary to align the base, and not with the purpose to raise it to the height.

A large thickness of the screed will dry for a long time and it can happen for uneven drying. Consequently, the quality of the solution is lost. When assembling the main cover, should wait for complete drying of the base.

Minimum thickness

Building regulations say, that the minimum performance thickness comply 20 mm. But much will depend on the material used in the work, 5 mm will suffice for this material, as self-leveling floor. And with sand concrete screed is usually poured on the minimum height 20 mm.

These requirements are based on the, that the base floor must be smooth and level. To save the budget with these figures maybe a combination of different types of ties. With minor irregularities cope tanker thin screed, a thicker concrete. In turn, reduce the height of the screed over the entire surface.

there are conditions, which must be complied with when installing the tie layer with a minimum.  A very important point - even surface, the absence of reinforcing elements. If we are talking about the technical facilities or industrial purpose premises, then a thin screed should forget. The same goes for kitchens, hallways and bathrooms. The best thing in such cases to arrange the thick screed.

A very important point - even surface, the absence of reinforcing elements. If we are talking about the technical facilities or industrial purpose premises, then a thin screed should forget. The same goes for kitchens, hallways and bathrooms. The best thing in such cases to arrange the thick screed.

There are certain requirements and the sequence of execution of works on screed with a thin layer:

- It is filled with gravel and sand, who carefully Trumbo special tool. In this case, it should be evenly raspredelno across the plane in the room.

- mounts waterproofing layer, which will be sufficient for the use of polyethylene film.

- Fixed on the surface of reinforcing mesh, after which there is exposure of beacons to best fill the prepared solution. It is worth noting, that reinforcements should not be based on the basis of, and "float" in the future ties. To do this, they are slightly raised above the surface.

- carried grouting concrete.

Since mainly tie layer and further has little reinforcing layer, of the materials should be selected rubble fines. Durability is not lost, as well as continue the height from floor to ceiling inside the room. Plasticizers when added in solution will give it better quality and strength.

Some features of the minimum thickness of the indicators provided for water underfloor heating of building regulations. Usually screed should be at the height of 40-45 mm from the location of the pipes. But even this distance may be shortened. This is best used as a reinforcing wire mesh diameter 0.3 cm. grid cell size must be 10*10 cm. Then there is the screed level reduction of approximately 10-15 mm.

In general the optimum thickness for uniform heat distribution and quality of the base and the floor inside the room is turned tiled. The entire layer will be sufficient to 65 mm. Much will depend on the diameter of the pipe used. Experts recommend screed thickness 60 mm using pipe MV12, and 65 mm - with tube MV17.

Prior to the beginning of the work should clarify all the indicators, which is able to withstand the floor slab. After all arranged in such a way screed over underfloor heating can create loads of up to 150 kilograms per square meter.

maximum performance

Also it does not provide indicators for, to the maximum screed in the apartment was obtained. but more 150-170 mm does not make sense to produce a fill solution.  It takes a lot of time, and forces. It makes sense only in the event, if the room is constantly creating a huge load on the base. It may even be a garage. Here, the vehicle weight affects together with existing equipment. This screed is to be fully justified.

It takes a lot of time, and forces. It makes sense only in the event, if the room is constantly creating a huge load on the base. It may even be a garage. Here, the vehicle weight affects together with existing equipment. This screed is to be fully justified.

The same applies to cases, when the coupler is part of the supporting structure. This device touches the floor and foundation in one whole. Even bad soil require grout to a considerable height.

Thick screed is more often used to align a large difference between the height of the indoor. But this is not the only way to hide the irregularities.

Before the work beginning it is better to decide on the, that will be used, Only coupler or additionally applied rubble or expanded clay. These materials can easily hide all the differences, reducing costs in the financial plan. High costs never justified, so you should immediately think about, to use backfill to reduce the height of the screed.

Performing ties the apartment with a height difference of 2cm requires adding to tie this indicator. At one portion, where is the height above, should arrange lower layer screed, and the other more. To get the optimal solution, should calculate all pre.

To obtain a good result when pouring the floor screed, even on the system warm floor, should make calculations and to determine best performance. Indeed, this will depend on the final result and strength of the whole structure future floor. It is very important to listen the recommendations of experts, who have considerable experience in carrying out similar work.