Any system of floor heating in the room requires attention not only during installation, but also by pouring screed, how to, and after work. Particularly different bay underfloor. After all, it is carried out several times during installation of the system, whether it be water or electric floor heating.

The concept and the need to

Under screed layer is meant a solution of, which is applied to the top surface. But it is with regards to floor heating, here screed plays every time the various functions, depending on the selected layer.

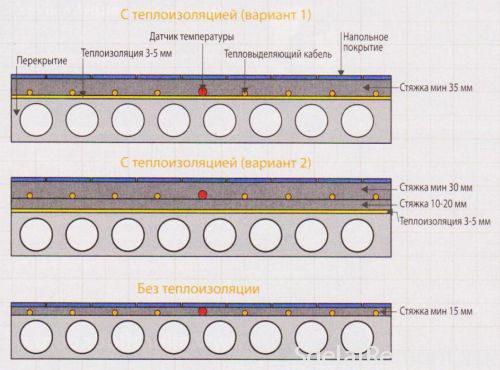

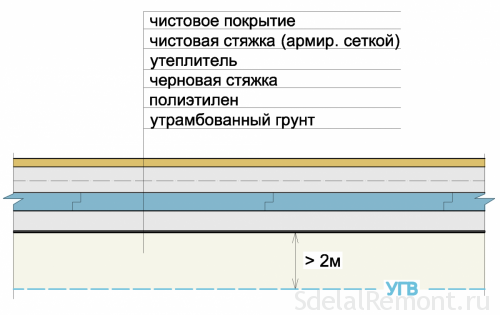

The first layer is carried out on the base of the Draft. It is increasingly used to create a flat surface for subsequent stacking materials. Basically, this layer is suitable for all surfaces, who have even minor effects. Instead of the rough layer of insulation can be used under the floor slab or prepared according to the rules ground.

The second layer is poured on top of the insulation layer. It will be designed for stacking on it underfloor heating cable. If you perform all the manual and Technology, the installation of a cable floor exercise will be much faster. As a result, each received result please.

Will only have to perform a "closing" cable underfloor heating, having carried out the fill underfloor. It will contribute to uniform heat distribution across the floor to, as well as the inside of the room. This layer fills the screed floor heating will subsequently serve as a surface for the flooring planks selected.

Apparatus final screed layer underfloor possible to arrange only, if verified performance of the entire system. The pressure therein must be kept at the required level. Otherwise, You have to remove the tie and watch, what are the problems in the underfloor heating.

Only this time these items will indicate, how to pour a warm floor, so it can warm up the air in the room from the bottom and up to the ceiling. If you move away from the technology and try to do everything in its sole discretion, then over time you will have to dismantle the surface and maybe even underfloor heating elements, electric or water.

to perform work requirements

screed underfloor heating no regulations, which spelled out the exact requirements, that apply to it. But there are rules, from which it is impossible to depart. Among them, the most important requirement - smooth surface covering for the floor heating system. But this item can be attributed also to the deck flooring, to get a positive result. Flat floor serve as a good basis for all subsequent types of work. Besides classical floor screed, It can be used when installing self leveling mixture. Everything will depend on the system itself underfloor, as well as the installation of features.

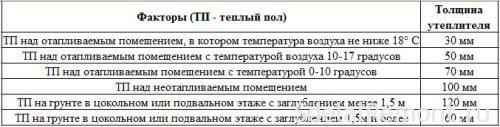

Another important requirement - the required level the thickness. Tie layer typically must be 30-50 mm. It is these indicators will provide a floor heating evenly over the entire area. In this case the substrate strength will be sufficient, to withstand external loads.

Optimum tie layer will allow it to dry equally across the area, without the appearance of cracks and subsidence. If they are formed on the surface cracks, that they will cause negative points, which include:

- Uneven heating of the floor, as well as heating a room or, generally, apartment.

- There will be some areas with increased temperature. In these places, the heating elements will be warmer than the permissible norm, which will lead to a reduced service life and failure.

If you already have and cracks, it is necessary to take all measures for quality repairs. Not unimportant factor - the time delay until dry screed. Usually this term is up 30 day. In any work can not be performed during this time, and wait until complete drying. Do not be amiss to get rid of in the early days of the draft and the sun's rays. The entire area in the same room temperature conditions have to be created. Some resort to the coating film of polyethylene screed.

rough casting

Experts recommend that prior to the sub-floor screed poshtukaturit wall, put the windows and other elements of the room. The same applies to existing communications (sewerage, electricity, etc.). The fact, what warm floor It can be placed exclusively on the flat surface, having no defects, pebbles, solution buildup. This is only a negative impact on the process of his work. If do the opposite, then it is best to lay on the surface of the plastic film, which is subsequently removed.

When it comes to insulation under floor heating, it should also lay down uniform, without izayanov. So that should make every effort to conduct a qualitative preparatory phase, before, as a pour warm concrete floor.

The solution should not be in the corners of the room, It should always be kept in a corner 90 degrees. Snug insulation to achieve otherwise not be able to.

There is a tolerance for irregularities. They typically +-5 mm. Otherwise, perhaps bowing pipes when installed, which will lead to the emergence of air pockets. If they are, and to overcome, it is necessary to perform the installation of the mixing unit with pump.

Only when all of these events are held, can be filled with a first layer subfloor. As for the solution, everything will depend on, what kind of options fill underfloor selected.

When filled draft, should await complete drying before laying insulation layer. But until this point it must be removed from the surface of the solution adhered all, removed all the debris and even dust. After that, do not forget at the perimeter of the room to fix the damper tape, serves as expansion joint itself floor screed.

Next, fit the insulation, produced another screed. On this floor filling under floor heating will be completed.

Preparing to fill underfloor

When mounted roughing screed, you can begin the installation of underfloor heating. For this select electric or water variant, which practically will not have differences in the subsequent implementation of the fill. But not everyone knows about, how to pour a warm floor. To do this, even to perform the established technology.

When the system is installed underfloor heating. It is necessary to check its performance. For this exhibition, even within 1.5-2.0 of the atmosphere. It must remain in the process of screed. But warm up system 25 degrees should not.

Mixing the solution

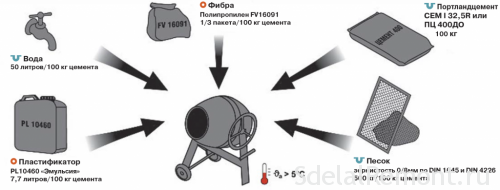

Density future tie will depend on the selected brand of cement. It is very important to understand, than the pour tube underfloor heating. Mostly recommended grade of concrete - 150-300. Everything will depend on the destination, residential or industrial building is. The concrete composition may include various additives, giving a solution of certain qualities.

There are features fill underfloor heating solution. Radiant Floor can not fully work with the cement-sand mortar. It uses a concrete-based dropout, including a fraction with small grains together with sand. Sold ready version, which is used for pouring. This is due to a better strength of the concrete, fewer cracks may appear, as well as better heat returns. The solution is to fill the water warm floors must meet certain requirements.

If you are using screening, to the 4 it is filled with pieces 1 cement portion. But sand and gravel has several other proportions - 1 to 4, as well as about 3.5 sand. In some cases it is necessary to conduct their own preliminary experiments to create the perfect consistency. Only then can carry out work on filling tubes in the floor. It is also worth noting, that in the implementation are already prepared mixture solution, in which only fill remain a certain amount of water, looking at the instructions from the manufacturer.

For such floor screed instead of the reinforcing element is generally used fibrovolokno, offering the best performance and quality, as well as having a somewhat lower cost, if we take into account the amount of material per square meter of floor space.

The choice of thickness

Layer under floor screed warm floor or it will depend on certain situations. Typically draft of sufficient thickness and will in 50 mm, but the finishing screed - 50-100 mm. Everything will depend on, the purposes for which the room is used. The thickness is selected to dwellings 70 mm, but industrial, with heavy loads - up 100 mm.

As for the fill underfloor, then there is need optimum thickness, to not only retain heat, but also a certain time. Otherwise, the boiler will have more time to work, spend time and money. Consequently, she is too thin should not be. The median of such ties should adhere in the area 70-80 mm.

During the construction or repair works to be understood, how to pour warm water floor, selecting optimal performance layer.

The process of pouring and the creation of expansion joints

When the system of floor heating exhibited, should think about preparing for the subsequent filling. It is for this exposed lighthouses. For their correct location should use the. Usually, they are made in the form of mounds of solution, supporting rail at the required level.

After that, you can begin to fill underfloor heating technology. After the concrete distribution surface, it must be tamped. For this purpose the vibrator, specifically designed for such purposes, rake, hoes or other handy tools. This is done, to all possible air bubbles are removed from the solution. When present, the thermal conductivity is lowered level, but, Consequently, the effectiveness of a warm floor after the screed will be lowered.

You can do without issuing beacon, and use the self-leveling mixture. Occurs immediately fill the entire floor space. When there is no confidence in their abilities to carry out the fill, it is best to seek professional help, who can do the job from start to finish.

For large areas of space, and after filling is finishing options screed floor heating, should arrange expansion joints. To be safe, they are held in the premises with an area of up to 20 m2. Sutures prevent occurrence of cracks in the screed during the expansion under the effect of temperature during the heating process. This indicates, why there is no need for a draft of ties. After their device, you can not worry about the quality of the entire screed during operation.

Possible mistakes

No matter what, that is done, before pouring the floor underfloor heating, or after system installation. Very important, To keep the technology and specific rules. It is very important to fix the damper tape, and layout done using a special tool.

Screed itself is usually arranged after, both completed plastering indoors. The process of preparation of the solution takes time, but the proportions must be followed without deviation. Otherwise, the quality of it is low, but, Consequently, and all performance will be reduced to zero.

To begin, all subsequent actions after pouring warm floor screed, you need to give it time to complete drying. All will depend on the solution, components and components. The less water, the faster the drying process. But it is worth paying attention to, that too small amount of water may result in a poor solution, cement will not be able to show all his qualities.

After all the screed levels is not always obtained even surface for a flooring floor covering type carpet. To do this, it is important to know the, how to pour screed on floor heating. In this case, further use leveling solutions, which are filled by small bed surface. It was such a warm floor after laying, you can include, use it for its intended purpose.

Each able to choose, a screed pour warm floor. Anyway, insofar as the technology, get a good result.