The most suitable base for laminate flooring in the room - concrete. But at the same time it needs the most work on preparatory activities. This indicates, that the choice of just such a floor covering should know about, how to put laminate flooring on the concrete floor. The sequence of actions will create a refined interior and excellent base options.

The choice of laminate

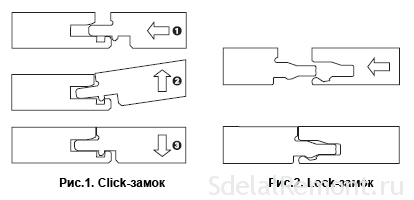

Initial action - shopping for a choice of flooring. The quality of the material is durable floor finish will depend, its quality. Particular attention is given to the tool joint. Laminate onto the concrete floor can have two types of locks: «Click» и «Lock». Each of them has its own characteristics during installation.

There is also a laminate embodiment of the device on the floor with an adhesive. Each panel is connected to each other by pre-lubricated with adhesive end portions. But this option is selected a lesser extent, since the presence of the locks laminate can be removed without damaging the individual elements and re-lay.

The choice is done correctly for a particular room and subfloor in it. So in the case of floor heating devices (water or electric), it is necessary to pay attention to the availability of appropriate labeling. After the usual laminate is capable of withstanding temperatures up to 27 degrees. Specific laminate not only has excellent heat transfer performance, but with constant heating and cooling does not lose its shape and quality.

Materials and tools

Laminate flooring is not only material, which must be purchased at the store. Essential to play and the substrate, do without which it is simply impossible. It can be expensive and cheap. It all depends on the preferences of the Executive.

All work is carried out with a specific list of instruments, rather than improvised means. You can make a kind of list:

- The layout will effect pencils, roulette and square.

- All panels together must tightly coupled. This will help achieve a normal hammer with a wooden block. will be enough 30 cm in length of the bar, to incite the laminate in some places.

- Cutting the laminate length and breadth can perform normal hacksaw. true, to carry out the cut will have a long time and labor costs. It is best to purchase a jigsaw, which is useful in the future when carrying out repairs in the apartment.

- Stationery knife or scissors.

- Plinth for completion are attached with the screwdriver or drill. It is certainly possible to fasten yourself with a screwdriver, but it is also time-consuming.

Among the supplies necessary to carry only screws with dowels, by means of which will be mount baseboards, having a large number of species, depending on the destination.

Advantages and disadvantages

Immediately necessary to determine the order, what advantages can bring laminate flooring over the concrete surface, and what challenges will be faced. The first number refers to the:

- Acceptable costs compared to other embodiments of the floor covering.

- Simple and fast installation process. Suffice it to read the instructions from the manufacturer, which goes to the laminate, and you can start. No professionals do not need, since everything can be done in-house.

- wear resistance, which is manifested in the ability to resist mechanical damage during operation.

- During the lifetime of a laminate almost does not change its original color.

- After laying laminate should be handled with care. But to implement it not be a problem to anyone. Especially if you choose a specific model of laminate, able to repel dust, endure the effects of different chemicals.

- As a huge assortment on, that you can select any option under the brand interior room. You can take the imitation of natural wood, with images of nature, fruit, forests, etc..

As for the negative aspects, then laminate them practically are not typical. Main - the fear of moisture. With constant exposure to water the laminate begins to lose its quality, appearance, deformed and foliated. In addition a large number of chemical components used in the manufacture of floor covering, indicating that it affectation.

Substrate preparation

The most important stage in the installation of the laminate on the floor - preparation base under it. It should hold before, like laminate is laid on the concrete floor. To this should be taken with full responsibility and fulfill all quality, that the floor was in perfect condition during operation.

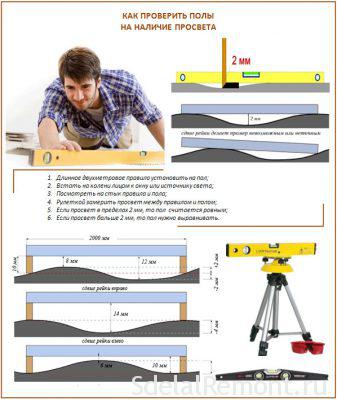

It can be easily without special tools to find out about, how much is not flat surface in the room. To do this, go to the floor rail, and placed on top of building level. In identifying inclines more 2 mm per 2 meters indoors, will have to produce alignment. To do this, first removed all the debris from the surface, after which the applied primer layer for better adhesion of the solution. But for this we must first determine the highest point in the room, from which to make calculations and, determine the thickness of the fill layer.

There may be cases significant surface damage in the room. Then it is necessary also to clean the base, embroider cracks and pits, potholes, then make pouring a cement-sand mortar.  But even this will not be the final version of the alignment.

But even this will not be the final version of the alignment.

the horizontal level will help to achieve maximum accuracy Self-leveling, after which cooking is distributed uniformly over the entire surface. During the day it dries up and gaining the necessary strength.

By laying the laminate on the floor can start only, when all alignment layer is completely dry. Otherwise humidity negatively affect the state of the floor covering, which will not be able to serve for a long period.

The choice of the substrate

The high quality of the floor covering, to some extent will depend on the option selected substrate underneath. It can be manufactured not only from natural, but also synthetic components. Among natural cork concerns, are of high quality, but at the same time and significant cost. It can be released in sheets or rolls and have a thickness of 2 to 4 mm. The substrate made of cork is combined with the laminate, having a cork layer. That will have a design with great sound and heat insulation.

The high quality of the floor covering, to some extent will depend on the option selected substrate underneath. It can be manufactured not only from natural, but also synthetic components. Among natural cork concerns, are of high quality, but at the same time and significant cost. It can be released in sheets or rolls and have a thickness of 2 to 4 mm. The substrate made of cork is combined with the laminate, having a cork layer. That will have a design with great sound and heat insulation.

For cork substrate should be as accurately aligned base. This result in the original version is not always possible to achieve. Besides laying the laminate on the concrete floor is best done on a film of polyethylene. It will be very convenient and easy to produce laying laminate onto the concrete floor.

We should not forget about the cheaper support options, made of artificial materials. Most often it is a foamed polyethylene (Izolon), which is available in two varieties - the presence of the basics of foil or without such a framework.  The most effective is, of course, foil base, which is laid out. It is used mostly to create a good space insulation. A great option - floor heating device of any kind.

The most effective is, of course, foil base, which is laid out. It is used mostly to create a good space insulation. A great option - floor heating device of any kind.

Even lower cost different "Poliform", which to some extent on the composition resembles "Izolon". All other options substrate somewhat similar to each other in appearance and content. One has only to select a particular option, to lay a laminate in the room.

editing process

When the above steps laminate assembly formed, you can proceed to its immediate distribution on the surface. Pre after buying flooring entered the room, where laying laminate on a concrete floor with his hands will be made, about 2 day, so he can get used to the atmosphere, the level of humidity and temperature indicators. This condition is mandatory for any performance.

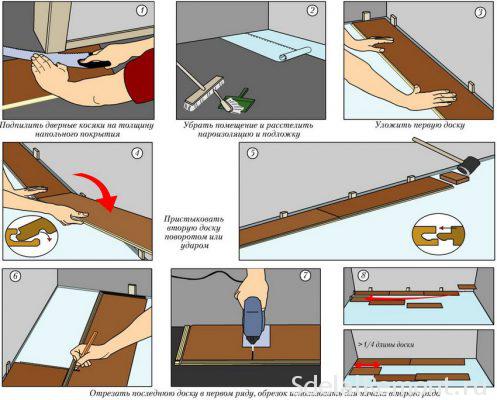

Start laying laminate - from the left side in the direction of the source of natural lighting of the room. In this case almost not visible joints. All subsequent steps should be performed sequentially, according to the installation instructions laminate:

- As the damping laminate of the external influence will act substrate, which is placed on a prepared and leveled base. It should be laid in the direction of laminate flooring.

- First row to go to directly to the wall. Between the wall panels and exposed wedges, which keeps the distance 10-15 mm. In the future, all this will not be noticeable, because it closes the Baseboard. For snug boards to each other, they should incite the hammer. But hitting directly on the panels in any case be. To do this, use a block of wood. These actions must be carried out throughout the process of installation of flooring.

- The second and subsequent number is to be shifted somewhat with respect to the first (Chess board). The most successful variant - to place the beginning of the new board in the middle of a number of previously deposited. Cut off part of the laminate is not necessary to throw out, as they may be useful in comparing the walls and other possible decorative elements in the apartment. These actions lead to a uniform load distribution on the basis of sex in the room. You can lay laminate own hands on the concrete floor without the help of experts.

- Depending on the tool joint, second row is going to completely or on one panel is connected to the first. If this type of «Click» Castle, then the number should be placed at an angle 40-45 degrees and insert into the grooves of the first row. After this stop to omit a number of laminate down until it clicks. All carried out in a similar way to the end.

- For the last row of characteristic width adjustment. The distance between the wall and rows laminate, taking into account the gap in 10-15 mm, After the panel is cut the last row.

In some cases it is necessary to create openings in the laminate, pipeline facilities. Originally applied to the cut line, according to which the segment and produced by means of jigsaw. In this case must also be a gap in 10 mm, which subsequently is sealed with special plastic plugs. This all suggests that, no special difficulties in mounting even a beginning artist should arise. selection video on working with laminate.

finishing plinths

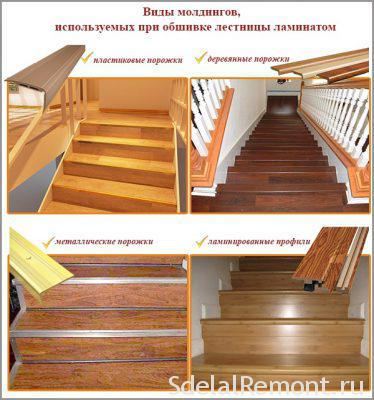

Laminate in the end should have an attractive appearance. With this purpose the plinth, which are exhibited on the premises along the perimeter walls. Initial action - screwing clamps to the wall. Selected pitch of about 50 cm. Will only make themselves skirting and slight pressure, to snap locks.

The final form of the plinth while acquiring, when they wore plastic caps on the corners, as well as at the joints of individual elements. They are simply inserted into existing openings and seal tightly to him.

Tips from the pros

Experts say that, that the main emphasis should be placed exactly on the surface preparation, conducted before, like putting laminate onto the concrete floor. After all, the slightest error of the base will have a negative influence on the state of the laminate, and the duration of its operational period. Alignment to better perform in two successive stages:

- Rough cement filling.

- Finishing using the self-leveling leveling compounds.

If the right to perform only final finishing base, any positive result will not work. All floor defects will appear as soon as possible. The same applies only to a rough finish, when there is no possibility to create a perfectly flat surface. detail a laminate squeaks and how to fight it.

Each step is important for each other. To get an answer to that, how to put the laminate onto the concrete floor, you must strictly follow the instructions from the manufacturer, respecting the specific requirements and rules. Only in this case will remain intact interlocks panels, and the concrete surface will not have a negative impact on the floor. Article written for https://sdelalremont.ru.