The laminate may be arranged on any version of underfloor heating. But to achieve the highest efficiency of the heating system, you must choose the most popular and best. It is here that a leader takes Infrared Heated floor. In this case, the underfloor heating is performed uniformly, and besides, the installation can be done very quickly and efficiently on their own. The choice falls in most cases on film flooring, since they do not have any negative impact on human health. It is worth noting, that there only needs to know about, how to properly and according to the instructions to perform the installation of the infrared floor under the laminate.

Necessary materials

To work with the floor heating system and the subsequent nastilom it should be reserved laminate materials and equipment, which will allow to make laying the whole "pie" with high quality and fast.

Directly to the infrared heat-insulated floor is best to buy a kit of components, where it will be all up to the little things. It includes heating film itself, special tape, having a bitumen base, clips for connecting the elements, thermostats in the required amount and temperature sensors. According to instructions, all cut, share, are interconnected. The main thing to look at consecutive points and not deviate from the installation technology for laminate flooring uk.

Under heating elements should produce flooring insulation material. Also useful in the work, and plastic film, playing the role of waterproofing. Depending on the size of the operations and operating conditions of a warm floor under the uk laminate, They can be used and contactors.

As for tools, is a set of very simple: screwdriver, pliers, nippers, knife, hammer, Tester etc. It can also be used and a specialized tool, intended for example,, for contact clip Infrared film floor laminated floor.

temperature restrictions

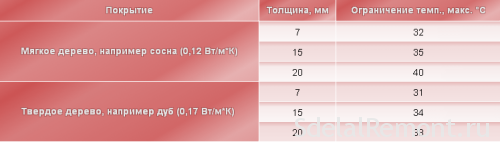

Any floor is able to withstand a certain temperature maxima. temperature is acceptable for classical laminate 25-26 degrees. This is due to the fact, that maximum limits are 27 degrees. From this comes, it must meet certain requirements for thermostat, exposing temperatures depending from the temperature sensor. In this case, the sensor itself is not on the surface in the room, and under the floor. So that certain limitations on the thermostat should be set, according to the appended table.

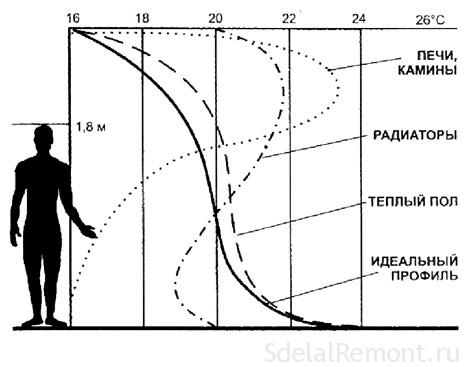

There may be areas with poor insulation. To achieve a comfortable temperature do not always succeed. But it has its own requirements to it. For intermediate floors of a building without arranged heat insulator, in the presence of wood coating thickness 15 mm, the temperature of the floor covering relative to the level of the room temperature should not be more than 6 degrees.

This all suggests that, that, if necessary to achieve a comfortable room temperature for the intermediate floor (between heated) and without the device insulation layer, enough power to heater 80-100 W per square meter, to eventually get 26 degrees temperature flooring.

Can use a heat insulator thickness 20 mm. In this case desynchronization air temperature and the coating can reach 8 degrees. This causes a further reduction in the cost of heating the air inside the room.

Planning

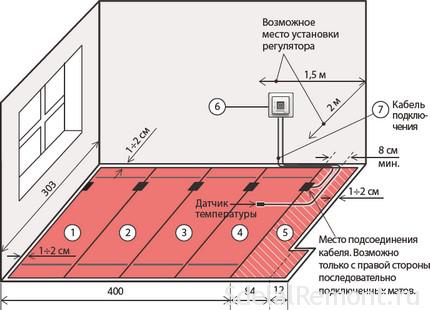

pre-up mounting Film floor under the laminate, should be drawn up on the paper chart, on which will be laying the heating elements. If the infrared Heated floor is used as the primary source of heat in the room, the film must cover the subfloor ranges from 65 to 85 percent of total area. It must not enter areas with built-in furniture, bulky items, because the heat will not heat the air, and will go back. This would lead to overheating of the separate portion of the film under infrared underfloor laminate.

IR floor under the laminate can be used as an additional (comfortable) the heat source. Then there will be enough, to cover the order of 40% the entire area of the room. Between the heating elements and the wall in the room must be made between the indentation 10 to 30 cm.  But we can not allow a gap between the heating strips laid more 40-50 mm. This will result in cold zones on the floor.

But we can not allow a gap between the heating strips laid more 40-50 mm. This will result in cold zones on the floor.

In drawing up the plan should take into account the factor, that the film should not lie on one another. It allowed only on that portion of the flooring instructions, which has no heating element.

Depending on the manufacturer and selecting a particular embodiment of a floor IR laminated floor, It will be different and the length of the sections. They can be cut arbitrarily to the need for efficient allocation of the base floor.

power calculation

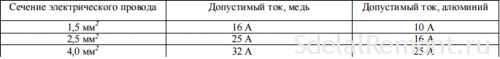

Another important step in Infrared floor heating installation under laminate - Calculation of heater power, vyschityvanie required number of thermostats, as well as the verification of electric cable in the apartment. Not always the last meets all those requirements, requirements for underfloor heating systems.

Allowable current will be different from the used cable and (section and material). The larger the cross-section of the electric wire, the higher the maximum current level. The best thing, if a system of floor heating cables are constructed of copper, as shown in table.

Preparatory work

This includes the stage training base for subsequent flooring infrared heat-insulated floor. It should be smooth and free of defects. This will initially roughing screed (in case of serious errors surface), as well as filling and finishing of self-leveling mixtures.  In some cases, sufficient will and mixture preparation and distribution of its thin layers, to reduce the level of sex differences.

In some cases, sufficient will and mixture preparation and distribution of its thin layers, to reduce the level of sex differences.

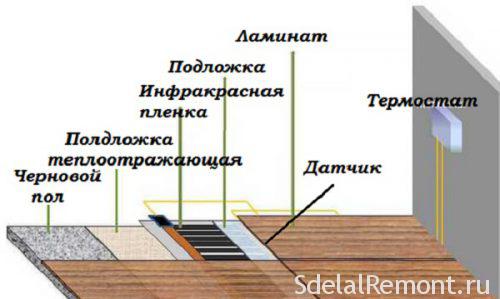

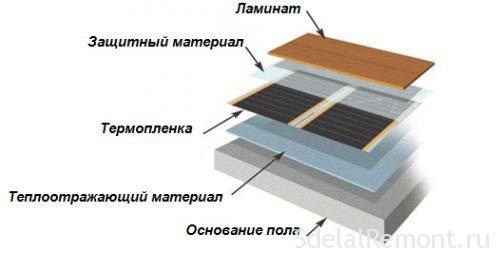

Once completely fill layer dry, you can start a device two very important layers - heat and waterproofing. true, Waterproofing is not always true. It is only necessary when applying infrared floor under laminate indoor, located on the first floor, as well as on damp rooms, which number can be attributed basement.

The insulation can be chosen as roll materials (Izolon) with a infrared radiant floor thickness 3 mm. They have a high efficiency, that allows you to save energy during operation of the heating system. If qualitatively perform a heat insulating layer, You do not have to waste energy and heat to warm the ceiling downstairs neighbor or basement.

On one side of the substrate has a reflective film. It is used to heat areas inside the room, and not anywhere as. Additional properties of the material for heat insulation - confrontation of moisture absorption, which to some extent can be used as a waterproofing and.

Laying sex film

Film IR underfloor must be cut and stacked according to a pre-arranged plan (scheme). As soon as it is ready, can produce its distribution surface, then secured with adhesive tape (scotch tape). The film should be laid on insulation.

There are certain requirements, which prohibit certain actions during installation of the heating elements. The film should not be fastened around its perimeter,. Enough to select only a few places, and for gluing choose tape with two adhesive side.

Concerning heat insulator, it should not be the basis of foil. Installation of infrared heat-insulated floor under the laminate should be made of copper tape, conducting current, a heat insulator. Laying the heating elements should be the length of the entire premises. Will be less wires and connection points, if the length of the film will reach the maximum. At the same time sellers of underfloor heating should be borne in mind, a maximum length of the film piece can be single. Under the plan, it is best to arrange a wire connection point close to the wall or in an ideal - under the baseboard or next to it.

Also, you are connecting all underfloor sensor to the power supply. Before the installation of laminate flooring as a check performance of the heating system, further to produce flooring dismantling. Do not be amiss to make a measurement with the ohmic resistance tester resistance of the system.

On top of the infrared floor heating up laminate installation necessary to lay a waterproofing layer of a polyethylene film. Overlap each subsequent series should be 30-40 cm. Joints between them are glued tape.

Tips for laminate flooring

If you are working with film warm floors, Arrange for laminate, it is worth paying attention to certain subtleties, which will be very important:

- If the room is elevated level of moisture, it is best to give up not only on the laminate infrared floor, but the floor under the laminate film.

- Maximum floor heating length of the film - 15 m.

- Fixing of film material can be carried out by means of such fasteners, like screws or nails.

- It is mandatory to be present ground heating system.

- Do not let bending underfloor film at an angle 90 degrees on an area with a length less 50 mm.

- Infrared Heated floor can not get close to other heating systems (radiators, stoves, fireplaces).

- It is forbidden to carry out the installation at low temperatures in the room.

- No amateur should not be. This mainly refers to making holes in the film.

installation of laminate Heated floor on the infrared may be performed in various ways, depending on the arrangement of flooring panels. The most simple and less costly material can be considered as options for parallel and perpendicular arrangement of panels, with respect to the front door and the windows located in the room. Particular attention is paid to the diagonal arrangement of the laminate, as there are significant differences - the beginning of the work carried out from the central part of the room to the walls, increased consumption of panels in comparison with other methods.

In some cases, you can not be purchased separately and laminated components underfloor, since a system of "two in one". Some manufacturers have decided to go ahead and create a uniform structure, which can be laid immediately on the subfloor and insulation layer. It takes much less time, and only increases the efficiency of. Article written for https://sdelalremont.ru.