Laminate refers to a number of floor coverings, having a high degree of wear resistance. Moreover, its service life will depend entirely on, how much quality for them in care in service, and what measures have been taken after laying for the protection of all the connecting elements. In the latter case, several variants of materials and tools can be used, what should be read in more detail.

processing is necessary

a laminate after processing stacking required to increase the duration of the maintenance period.  Despite, that the floor belongs to the synthetic, it requires additional processing to enhance the moisture protection layer. In addition, another option - the restoration of the old slats, who have seen many things in his lifetime. Damage to appear at constant walking thereon, as well as when you drag furniture from one place to.

Despite, that the floor belongs to the synthetic, it requires additional processing to enhance the moisture protection layer. In addition, another option - the restoration of the old slats, who have seen many things in his lifetime. Damage to appear at constant walking thereon, as well as when you drag furniture from one place to.

If the time to process the slats special facilities and materials, then not only do not have to produce laminate repair, but his life will be significantly increased. In addition, in through the seams and tool joints no longer gets wet outside, which is capable of causing serious damage to the floor covering.

Preparatory work

Before, how to start work on the laminate processing after installation, should undertake a number of preparatory activities, including to acquire the necessary material to work. The latter can be attributed:

The latter can be attributed:

- fabric piece, which should not be hard.

- Putty knife, having a base of rubber.

- Respiratory Equipment for work, able to protect his face from possible hits of special funds, which will have to work.

- soft sponge.

- gloves, protect hands.

Regardless of, what at the cost of laminate and a manufacturer of, will still be faced with a problem - a very sensitive tool joints. They need careful handling, not only in the sub-floor assembly, but after the final application.

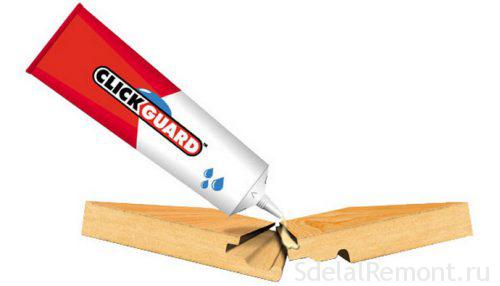

The highest density achieved in the case, if they during installation treated with a special wax. They will fit tightly to each other, and further protect the joints between lamellae. There are laminate model, which have been processed with wax. Thus it is necessary to pay attention to, often negligent sellers trying thus to hide the deficiencies and damage to the lamellae.

After laying the laminate on the subfloor, it should be thoroughly vacuumed, to get rid of possible debris and even dust. This all further can easily get into the seams of the laminate, threatening to destroy during the operation and appearance of extraneous sounds, crunch.

To work a large number of means can be used, represented in hardware store. Their choice is to pay particular attention, looking at color schemes and method of administration. Do not be amiss to consult, not to spend money for nothing.

Using wax formulations

Each artist will tell about, that the most "dangerous" places, susceptible to change during operation - or interlocks, simply put, the joints between the sections.  In these places easily gets wet, and other irritants laminate. They can get not only from the outside, but also from the concrete floor in the form of condensate.

In these places easily gets wet, and other irritants laminate. They can get not only from the outside, but also from the concrete floor in the form of condensate.

With this problem can handle liquid wax. It is worth while only paying attention to, that the application should be made only on themselves interlocks, and not alone laminate. You can select specific tasks, which can handle the wax composition:

- The absence of squeaks during operation while walking.

- Increased strength interlocks, It reduces the level of deformation under loads from outside. This can be the location of the furniture themselves lamellae, its movement, etc..

- Wax composition is excellent help during installation. laying laminate it will be possible to perform faster and better.

The easiest way to buy a wax composition and to perform the processing of the slats. Ready laminate option would cost much more, which is not very well be subject to the budget execution. In this case, the material itself is best to carefully examine before purchasing.

It is worth noting, that he laminate in any case not be treated with wax, since it only damage the protective layer of the floor covering. Manufacturers themselves also do not perform for this reason.

With wax compositions should work closely and for this there are certain rules. All of them are usually prescribed on the package out of funds. Each composition thus requires special conditions of.

For applying liquid or pasty wax should use ordinary brush. Lock completely covered except for the presence of certain portions with protective elements. In this case, all the work is best accomplished before the pre-stacking.

Polish laminate

After laying laminate to increase the level of protection can be applied polishes. They are also widely used in surface treatment has over a certain operating period for updating. They are sold not only in the form of a liquid spray, but also in solid form. With all of this is not necessary to carefully rub the surface of the tool.

When applied using a sponge, has been selected for the preparatory phase. Special requirements for it are not available. Polishing follows using a soft piece of fabric. Application carried out along the lamellae, to end up with a uniform color, without the formation of streaks or spots. More time and effort necessary to spend when applying solid formulations, which may be a special mastic.

The easiest option - the use of water-based emulsion. They are diluted in a certain amount of water. After this will only wash the floor surface the solution and enjoy the beauty. But the effect will be considerably lower, than using polishes and pastes. Them enough time to apply 2 in year.

Advantages of mastic

If you really want serious protection laminate after stacking, it is best to use a special mastic, having additional flavorings. The connections are becoming more persistent and acquire the best quality.  When all of the rules in force, inside the flooring will not penetrate moisture and dust. With mastic can achieve the following objectives:

When all of the rules in force, inside the flooring will not penetrate moisture and dust. With mastic can achieve the following objectives:

- Guarantee protection from humidity.

- All floor elements are connected securely and reliably.

- Not facing the floor covering external mechanical action.

- On the lamellae themselves will not start to accumulate dust.

If you know, that at the time of purchase material it has been processed by special means to protect, then should not use mastic. Improve the quality of unlikely, but can easily damage the floor.

When various defects on the laminate surface during operation, great help solid mastic. The application of funds is carried out only on that site, which is damaged. At the end of the work carried out a thorough polishing of the surface by any means at hand (fleecy cloth). May be the remnants of putty on the lamellae. In this case, clean them with a plastic spatula.

Features of the application of the sealant

After laying laminate, even specialists, may appear gap between the slats. With a view to getting rid of such a defect is typically used special sealant, represented as putties. Its popularity is increasing with the passage of time due to display the qualities, best, than the previously discussed options. Among them:

- Elasticity.

- Durability.

- Humidity resistance.

- perfection.

- Reliability.

As part silicone sealant is available, that shows some of the above qualities. AT during operation for this tool is not afraid of high temperatures, and sealing of joints and gaps of the laminate is performed at the highest level. the main thing, select the tone in tone with the sealant laminate surface. In this case, it will remain invisible and imperceptible.

Dosing grouting

In the case of the slightest damage interlocks Moisture easily falls to the lower layers, endangering the quality and durability of the floor covering. To avoid this special grout used. It is perfect for, to get rid of chips or holes appearing.

Grout is used most often in those areas, where there is a threat of increased moisture - kitchen, bathroom, restroom, children's rooms, dryers, etc.. The joints of the laminate must be protected and there, where people are constantly walking, move bulky items, furniture.

There are established procedures applying grouting, which includes the serial number of actions. The gel is applied on the longitudinal slat side and severally laminate by castles. Moreover, these slats must be connected before, how the grout dries. Excess outside tread part means, you can easily remove. true, any excess is removed after 15 minutes after application.

After laying laminate sequence of steps for applying the following grouting:

- The joint slat cleaned thoroughly from dust and dirt.

- Use masking tape, to create a protective layer on the remaining portion of the sipe. This will prevent damage to it.

- Applied grout using a rubber spatula. He also carried out surface leveling.

- Using a dry cloth after tight 15-20 minutes removed not only masking tape, but all possible sections with balances to protect.

All of the above means for the protection of the laminate after the installation will allow him a long time to keep the original properties. Its reliability is markedly increased. In some cases, special tools are used to restore original appearance during operation.

Article written for https://sdelalremont.ru.