Very popular among laminate flooring uses. This is due to a large number of positive qualities and singers reviews. Thus it is necessary to pay attention, laminate that requires very careful attention to the process of leveling the subfloor in the apartment, where to carry out repairs. It is for this reason, you should consider the options for floor screeds, that can be used before laying the floor covering.

Forms for leveling screeds

Device screed carried out with a view, to the ground under the laminate was perfectly flat. This will contribute to the durability of the whole structure, and in absence of negative displays operational period.

Screed is a division into two main types, each of which is different from each other used materials and tools, as well as carrying out the work:

- wet screed. The floor in the room is filled with prepared cement-sand mortar, after which a uniform distribution over the whole area.

This process is characterized by increased complexity, where you can not do without the accuracy and compliance with all the details. Additionally, "pie" can be strengthened by means of reinforcing mesh or added to the cement-sand composition specific additives (fibrovolokno). In this case, the base is not only durable,, but strong, able to withstand external influences easily. Another embodiment of the wet casting - application of self-leveling compounds, which is gaining interest. The process of installation is significantly reduced screed, but they can only be used when no more roughnesses 20 mm. In all other cases, it is impossible to do without the classic solution of the sand and cement.

This process is characterized by increased complexity, where you can not do without the accuracy and compliance with all the details. Additionally, "pie" can be strengthened by means of reinforcing mesh or added to the cement-sand composition specific additives (fibrovolokno). In this case, the base is not only durable,, but strong, able to withstand external influences easily. Another embodiment of the wet casting - application of self-leveling compounds, which is gaining interest. The process of installation is significantly reduced screed, but they can only be used when no more roughnesses 20 mm. In all other cases, it is impossible to do without the classic solution of the sand and cement.

- dry screed floor under the laminate. Here, the process does not take very much time, but also requires efforts. All available projections, dimples, potholes or other irregularities in the subfloor room backfilled expanded clay layer of a certain thickness. After that, top will only produce packing plywood sheet or chipboard. But here is the reliability and duration of the use of such "pie" is not enough. This alignment method subfloor applicable in most cases the presence of the surface of the boards. Rough substrates must be carefully polished, whereupon plywood sheet is laid over the whole area. Consequently, You can be dispensed with expanded clay.

Selection of a particular embodiment of a laminate floor leveling will depend on the artist, as well as its capabilities. In any case, you should stick to technology and sequence of all steps.

Requirements to the screed

The floor under the laminate must be qualitatively lined. Thus up to the deck floor covering, laminate floor screed should get tough. It is these demands are made by the manufacturers of laminate panels. Per square meter of floor space only a small elevation change allowed, which shall not exceed 2 mm. You can not even talk about that already, It is not allowed in the presence of various surface damages such as cracks, potholes, etc..

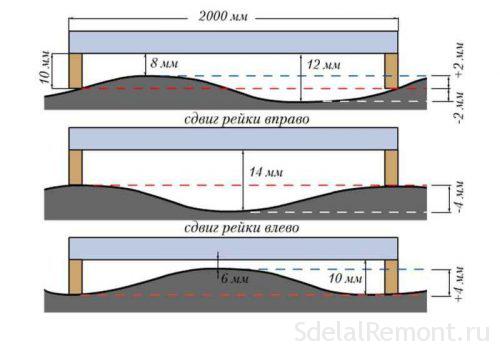

To determine the base line definition can use a rule-, whose length is about 2 m. It gradually laid on the floor, trying to find a level difference. All errors, to be discovered before laying the flooring, They should be immediately removed.

If the errors are insignificant, it is possible to leave them. All of them will be hidden in the future when laying pads laminated floor. The main thing is to choose its quality version. Several layers of the substrate will still be able to get rid of the potholes and significant differences.

In the absence of a future communications flooring, tie is high in 35-45 mm. But here you need to know immediately about, that the drying period of the "pie" will be about a month. During this time you will not be ready to further types of work. Otherwise, immediately arise with the quality and durability problems. When the funds are sufficient, you can buy ready-mix (fast drying option) who use the.

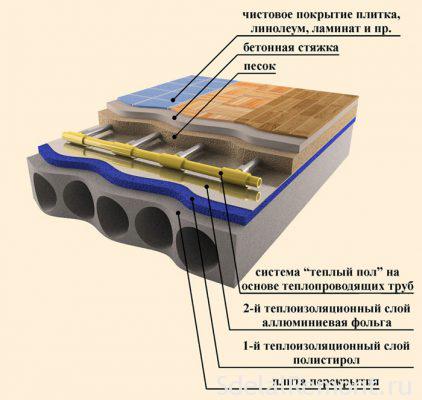

Under the layer of concrete is not superfluous to produce a layer of insulation, special, if audibility between the floors and floors of the underlying at a high level. In this case, the reinforcing layer is added to a solution of, lest there be cracking fill layer.

functions

When a floor covering for the subsequent laminate flooring, the filling layer performs several basic functions:

- alignment ground, that is the primary task of the solution prepared.

- Masking communications and pipes, which could create an obstacle for the normal creation of an interior room. In addition to tie system can be placed water or electric underfloor.

- rough base It becomes more robust and reliable, able to withstand numerous external mechanical influences.

- Sound and thermal insulation. Thus it is necessary to provide for and to buy the necessary materials.

- While walking on the floor creates a uniform load. The same applies to straddling furniture, interior decorations. She will be able to handle even large schools, without damaging the flooring itself, which will lay.

Materials used

For each type of screed provided a list of materials and tools for the job. This is due to the process and technology, which differ among themselves.

So, for dry leveling subfloor for laminate, You have to buy not only the plywood sheets or plates, and screws, hacksaw, drill, roulette, etc.. Of course, all usually have in the arsenal of the experienced builder.

Screed prepared from sand and cement solution, all additives and ingredients, need to buy another primer, level (best laser for accurate calculations), usually a certain length, mixer, beacons to aid in alignment, spatula, etc.. The mixture is in this case pre-preparing to carry out all the work. It is important to knead all the necessary components, without deviation. Particular attention is paid to the amount of added water. Too rare mixture will not be able to give a ready base of the fortress, will dry much longer, Yes, and probably the whole crack.

Recommendations for the device ties

It is important during compounding proportioning. This will depend on the quality of the entire casting for alignment laminated floor. Normally, all this is written on the packaging out of the mixture, if it is a ready option. Otherwise, you should follow the recommendations from the experts. For grout will not fortress.

To work with self-leveling compounds must also be able to. Spilling and tie should be carried out at each site again, that was not in the subsequent wells. This is due to the fact, such a mixture tends to sag during the drying. In addition, it has a very high degree of fluidity.

Upon completion of work areas can be formed with a drawdown, even when the beacons are the, previously exposed. To get a flat surface, beacons removed or polished as possible before full alignment. The formed voids are sealed in the same solution. Before drying the mixture on the floor can not move or perform other types of work. All this only hurt the surface and from work will not be any result.

Production screed of sand and cement

As I mentioned earlier, "Wet" version of leveling the subfloor under the laminate requires attention and experience. There is even a sequence of works, that will come to the desired result:

- preliminaries, when it is necessary to take measures to remove dirt and dust from the surface. This will help building cleaner.

Is also deleted old coating, if there is significant damage. Dry screed under the laminate can be applied to existing voids and cracks. Performed their sealing. Prior to pouring the solution surface covered with several layers of primer to improve adhesion level.

Is also deleted old coating, if there is significant damage. Dry screed under the laminate can be applied to existing voids and cracks. Performed their sealing. Prior to pouring the solution surface covered with several layers of primer to improve adhesion level. - That the mixture is uniformly distributed over the entire area, exhibited beacons. For this there are several options, each of which differs from each other. The easiest way - Mortar Beacons, which subsequently did not even cleaned, but remain in the fill layer. Lighthouses are exposed on the level, pre-determining the zero level in the room. As benchmarks can act and stretched rope, which also adheres to the existing level. The specific method depends on individual decisions.

Prepared according to the rules and proportions of the solution is distributed over the area in a room, from the farthest from the entrance angle. This is due to the fact, it is better to pull out the excess mixture to the front door, than in the reverse direction. Everything is done with a focus on pre-exposed lighthouses. Thickness filling will depend on the destination coupler, existing initial rough base, drop the floor level.

Prepared according to the rules and proportions of the solution is distributed over the area in a room, from the farthest from the entrance angle. This is due to the fact, it is better to pull out the excess mixture to the front door, than in the reverse direction. Everything is done with a focus on pre-exposed lighthouses. Thickness filling will depend on the destination coupler, existing initial rough base, drop the floor level.- Once distributed solution scrapie and dried for a predetermined time, should be applied to the primer layer further. Almost never get a perfectly flat surface, to proceed to the laminate flooring. In this case, you should consider filling layer self-leveling compounds.

But here it is worth remembering, that under the laminate is carried out one of the options presented (concrete screed or leveling layer). Everything will depend on the initial evenness. Self-leveling mixtures used in floor elevation differences of no more than 20 mm.

Self-leveling mixture

It refers to the number of expensive options for alignment subfloor.  It's very convenient to use and operate. The main requirement is a good base to prepare, remove excess dust and debris, that can affect the quality of adhesion with the base mixture.

It's very convenient to use and operate. The main requirement is a good base to prepare, remove excess dust and debris, that can affect the quality of adhesion with the base mixture.

With such defects, as cracks, chipped, unevenness of the mixture is ready to cope on their own. After pouring the mixture on the floor under the laminate should generally using razravnyat. Will only go spiked roller, to get rid of air bubbles. the drying process does not take long, then it is immediately ready for laminate flooring on the prepared backing.

Dry the alignment

For laying the floor covering can be selected and dry laminate under a screed. Most often, this is done on a wooden base, tentatively verified by a qualitative condition. If the board is rotten and very old, then replace them with the best in the new. Available bumps in the plank floor are cut or grind. All will depend on the surface state. In some cases it is easier to get rid of the old base and lay a new.

When aligning a sheet of plywood laid over the entire area in the room. laying carried out for each other, leaving a slight gap. In the presence of decorative elements on the alignment path, you can cut the plywood using a hacksaw.

On the boards can be stacked sand-cement slabs. Laying performed similarly with plywood. Fixing is effected by means of screws. Flatness laying checked using a spirit level, which can be purchased at any hardware store. Next, the laminate can be laid on a dry screed.

Another "dry" method under the laminate floor leveling - expanded. He is in demand due to ease, reduce the burden on slabs with significant Elevations. The strength in this case remains at a height, it is able to last for a long period.

In addition to the classic functions, expanded clay has insulation properties, environmentally friendly, It does not issue into the environment of harmful substances. This "cake" is very well keeps the heat inside the room. During the operation, you can not worry about, such that the floor will rot, formed therein mold. Material cost is not high, and you can buy it in any hardware store. Laying laminate on dry screed is performed by all the rules and requirements.

In addition to the classic functions, expanded clay has insulation properties, environmentally friendly, It does not issue into the environment of harmful substances. This "cake" is very well keeps the heat inside the room. During the operation, you can not worry about, such that the floor will rot, formed therein mold. Material cost is not high, and you can buy it in any hardware store. Laying laminate on dry screed is performed by all the rules and requirements.

If you do not want to independently carry out all kinds of work, you can contact the experts. They certainly know, how to arrange a tie for laminate flooring, and what is its option to choose for good alignment.

Article written for https://sdelalremont.ru