Every endeavor to create in a residential area a maximum of comfort and relaxation. The first step is to think about the quality heating, where preference is infrared heat floor. This is due to the manifestation of its large number of positive features, as well as the ability to heat the air in the room from the floor. But the same sex is not enough, as it is necessary to think about the choice of flooring. The best option in the device floor heating using infrared film - laminate. But here it is very important to know the sequence of all the works on installation of the floor under the laminate film, to get high quality results.

What is infrared warm floor?

Infrared Heated floor, in fact, is a surface heating method, which is carried out by raising the temperature of the heating elements using electricity. The infrared heater has special conductive strips, which allow electricity to pass through and heat the surface. Electricity flows through the wires and heats the floor evenly. It is this system that determines the complete tightness of the infrared floor and its resistance to high humidity..

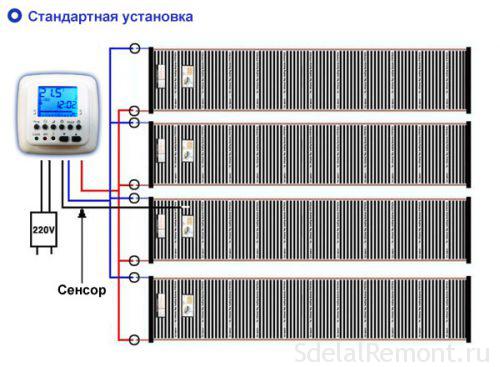

This design has a thermostat. With it, you can independently change the temperature in the room and in its individual zones.. Infrared floor heating is absolutely harmless to human health. It only emits negative ions, thereby providing even a positive effect.

Another feature of this floor is that, that he warms up the whole room. This is due to the fact, that a heat-reflecting lining is installed under it, which gradually heats objects, located on top. In this way, this device will heat the floor, and not the ceiling of the neighbors in the case, if it is installed in the apartment. Infrared floor does not heat the air, therefore heating is gradual and correct.

Besides, many manufacturers claim, that infrared floors do not dry the air. This statement is only true if, if they are used separately from the general heating system, but together, both systems dry the air and reduce the humidity level in the room. Although manufacturers often cite such benefits, how air ionization and health benefits, this radiation can still lead to allergic reactions. In this way, the system is not hypoallergenic and may cause some problems.

Features of the infrared film floor

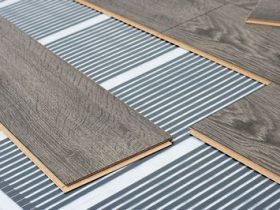

The infrared floor heating element is a specially made foil material. Such a film is simply covered under the floor covering and does not require a special cement screed for its installation.. Such its properties can significantly speed up the installation of the film floor and reduce unproductive loss of time during construction.. Warm floors of this type are allowed to be covered with any kind of flooring, which are widely used today in general construction works.

In this situation, traditional coatings can be used as a “finishing” floor., such as laminate, parquet or linoleum. The only coatings, which are not recommended for this, are carpets and tiles. In the case of wood flooring, you only need to worry about, so that the operating temperature of the heating element does not exceed 28 ° C.

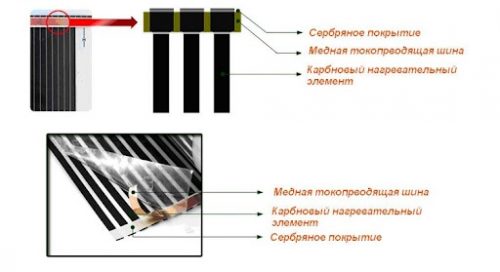

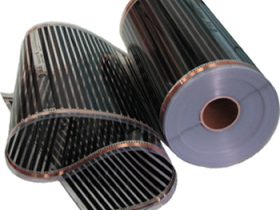

Foil floor can be made in two different designs; according to this, it is divided into bimetallic heaters and carbon film.

A high temperature floor with a bimetallic heater usually consists of two dissimilar layers, one of which is made of aluminum alloy, and the other is copper alloy with various elements. Carbon film contains two layers of copper, lavsan and carbon elements. Such films are usually made in the form of finished rolls., which are easily cut into pieces, suitable for covering.

Rod electric floor consists of special flexible carbon rods, which are placed in a thin cement screed (or attached to a special tile adhesive) and are shaped like a kind of rugs. This floor can be installed under any floor covering, which can be used as a standard tile, and as traditional floor coverings (carpeting, linoleum, laminate, etc.).

toolkit

Before joining should consider buying the necessary material, from which it will be not only the floor heating system, but laying a floor covering in the form of a laminate. Do not waste your time and acquire all of the components Infrared floor heating separately. Currently, it is possible to acquire all included, where there is even a small parts, required during installation.

The plurality of heating components included:

- Infrared film to length. The calculation should produce pre, that in the future not to be distracted from work.

- thermoregulator, Allows the user to configure the required level of temperature or incorporate into operation all the heating system at a certain time.

- temperature sensor, which is installed under a floor base laminate. Its main purpose - to determine the level of the room temperature.

- terminals.

- The insulation kit.

- Wiring to connect all major components with each other and connecting them to the network.

- User's manual underfloor heating, as well as the warranty card.

In addition, it needs to purchase certain materials for the process of mounting a floor under the laminate film. This includes pad under floor heating system, and polyethylene film, placed underneath the floor covering. We can not forget about the tape, with which you can join the ranks of the heat-insulating material or film contacts the floor, Arrange for laminate.

at laying laminate on film floor will also have to buy a polyester film or an alternative material - substrate, absorb noise and sound.

Design

To achieve the desired result and get a warm room with excellent floor finish, will have to pre-plan everything correctly and establish a distribution circuit of floor heating components, if necessary, under the laminate.

Originally defined working area, where the installation of film floor will be made. It will not include areas, beneath the bulky furniture, as well as other objects, that will create obstacles for the normal heat transfer.

Additionally, the circuit emerges on paper, where you want to position the film floor laminated floor. Subsequently, the resulting scheme is applied to all documents underfloor, to be able to not only monitor its performance and to make repairs if necessary, but also to carry out the installation of all other components of the "pie" subfloors indoors. After all, when screwing the individual elements or other types of assembly work can damage the heating component underfloor.

Additionally, the circuit emerges on paper, where you want to position the film floor laminated floor. Subsequently, the resulting scheme is applied to all documents underfloor, to be able to not only monitor its performance and to make repairs if necessary, but also to carry out the installation of all other components of the "pie" subfloors indoors. After all, when screwing the individual elements or other types of assembly work can damage the heating component underfloor.

Preparing for installation

initiate proceedings mounting film sex under the laminate and can be on their own. Suffice it to read the instructions from the manufacturer, as well as the heating elements of the device technology. This allows you to save money on calling experts.

Any debris should be removed from the surface, so it does not obstruct the placement of all components. If there are irregularities of the subfloor should get rid of them. If they are minor, it is sufficient to arrange filling layer with self-leveling compositions. With significant differences in elevation and surface defects have to produce floor leveling concrete screed. For further preparatory work can start only, when the solution has completely dried and clutched. Otherwise, the quality of floor heating can not get.

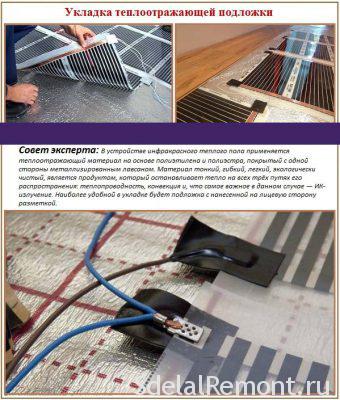

Thereafter, in the base made laying a waterproofing layer, having a polypropylene coating. It will be a kind and substrate for the system film sex. Installation of floor heating under the laminate is performed subsequently arranged on the insulation layer qualitatively. Laying of heating floor under the laminate must be done metallized side up. Moreover, all joints of adjacent rows of thermal insulation material must be glued tape.

Attention to the substrate

Under Film warm floor, hosted under the laminate, it is best to use a substrate in the form of foamed polyethylene or polypropylene. It is covered with Mylar film, having a metallized layer. It is all together enables the heat is evenly distributed over the entire surface.

If it is arranged qualitatively pad a film floor, it will be reduced by the cost of electricity. After the order is saved 80-90 percent of the total thermal radiation from the heating elements.

Besides, what pad arranged under floor heating system, such material should be put under further flooring and flooring, which in our case is a laminate. It should be compulsorily separated from the heating elements. Otherwise, over the life of the "pie" underfloor heating, between the laminate floor and will be manifested as a base layer called, leads while walking to the appearance of knocks and sounds.

The thickness of the substrate for laminate flooring on the film should have a thickness in the 2-5 mm. There is an option and specialized support, having elevated levels of heat during operation of the heating system. it also acts as an additional layer of insulation and subfloor, It is a kind of shock absorber, It allows you to get rid of possible minor differences of the surface level of the plane.

The best option of the substrate under the film laminate floor - polyethylene in rolls. It can perfectly be combined with such building materials, as concrete, cementitious compositions, able to resist the emergence of fungal attacks and the emergence of bacteria. The main requirement is to implement it further and the quality of surface care.

successive work

After that, as the surface of the floor in the apartment aligned to a horizontal position and is formed by stacking the substrate Heated floor, you might think about the distribution of the heating elements. They should be placed according to the previously established scheme, based on the "working" floor space. film strip under the laminate floor can be cut to the desired length and, if necessary, the creation of the bend. This increases the efficiency of the heating base.

Also produces equipment thermostat and a temperature sensor, which combine to create conditions favorable to maintain the desired temperature level. You can choose to set a limit, as well as select ON and OFF of the heating elements.

At the end turn to the work of a warm floor will only have to connect all components to the mains. the main thing, voltage to the cable corresponds to the power of the heating elements. If such a measure is not, you'll have to replace it with a new, on the basis of the required parameters. We should not forget about the mandatory grounding device.

Laying of laminate

after checking underfloor heating systems, test it, You can proceed to laying on the laminate film floor. But not everyone will know about, how to put a warm floor under the laminate properly and in accordance with all requirements. Required stacked substrate, serving as an interlayer between the two components. Will only choose the flooring floor covering (parallel, perpendicular, diagonal) and get to work.

It is worth noting, each version of the distribution of the laminate floor surface in the room has its own characteristics. This is what the instructions on installing laminate film floor, which defines the sequence of actions, as well as the main recommendations, niceties, which you should pay particular attention.

When laminate loaded, is put along the walls in the room by skirting the perimeter, which are fixed to anchors with interlocks. Of course, you can choose and completely different options, including qualitative thresholds for smoothing the transition between rooms, in the doorway. Everything will depend on the requirements and the financial component of the issue.

Tips from the pros

During installation laminate on film floor, as well as the distribution of the heating elements and the connection of all components of the network, it is best to follow the recommendations from the professionals, which will provide high-quality and comfortable heating subfloor.

- When performing work on their own, it is necessary to choose those systems, which is for this purpose and are produced. They include detailed instructions on how to conduct work.

- The use of an additional layer of insulation under the heating elements will cut energy costs, as the heating will be most effective. No loss will not occur, all the heat to go into the room.

- If the climate is different in different rooms, the heating system is better to combine, rather than choose one specific embodiment. Besides, one loop can not be located in different rooms (in the room and on the balcony at the same time). Should produce a separate connection, where exhibited distinct temperature. In this case, it will be easier to choose the type laminate for flooring.

- In the presence of the bottom of the basement or cellar without heating, necessary to perform additional waterproofing layer for heating elements.

- Wire-saving can be achieved in the case, if the temperature sensor is located closer to the central part of the whole structure. Location must choose a, which is likely to be the lowest temperature. Wires necessarily placed in the corrugated tube.

- Facilities with high humidity levels do not like film flooring, as well as a floor covering, as laminate. All of these designs quickly will fail and will not bring any effect on the operation of the heating system. For this reason, laying Infrared warm floor under the laminate is not carried out.

- Maximum floor heating film length must be no more than 15 m. During installation of the film warm floor under the laminate necessarily ground must be arranged.

That will have a qualitatively warm up the room without reducing the distance from floor to ceiling. Besides, using the laminate can be complemented perfectly with any interior option due to the diversity of colors and images on the surface.