Increasingly, as laminate flooring is selected. This is due to a lot of his positive traits, which it is manifested not only in the material itself, but also in the installation process. But laminate requires a qualitatively prepared basis. For this embodiment, there are many, among which may be mentioned, laying the plywood to the concrete floor under the laminate. The main thing to choose a suitable plywood, what are the relevant recommendations.

Features plywood

Plywood selected on several grounds, among them acceptable material costs and optimum quality. With regard to the latter it is necessary to talk more in detail and highlight the most basic of them:

- An extensive range of applications due to plywood strength characteristics. It is perfect not only for the zone, but also industrial facilities, office space.

- Excellent quality insulation.

- Long operational period material.

- Not present extraneous smells in the room after plywood packing on the concrete floor under the laminate.

- It can be used with the device in the room floor heating systems of various kinds (water, electric).

- The convenience and practicality due to the considerable size of veneers.

- Simplicity mounting.

- The rigidity and high wear resistance.

- Resistant to a variety of synthetic means, that can be used in the process of cleaning.

- Confronting external action (pressure load).

But this is only the basic features of the plywood sheet. In the process of laying on concrete floor it can be of different types and grades, clarifies that when buying. With regard to the brand of the material sheets, it will be determined depending on the level of water resistance of its connection. Pay attention to costs and grade plywood, which will be used for installation on a concrete floor. Additionally plywood surface can be pre-polished or not, have different sheet thickness, and dimensional characteristics.

Separately taken veneer sheet may be used under different circumstances. This indicates, it should think in advance about the conditions, where it will be used. The material itself may be different amounts of formaldehyde, that will indicate the level of environmental safety.

The correct choice of plywood

During a visit to the store building and the purchase of veneer sheets, the best option would be considered a birch. It is perfect for laminate 2nd grade. With an average water-resistant plywood on concrete floor It is labeled FN, that says about the purpose for individual housing construction.

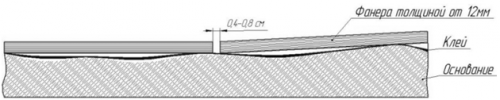

When we are talking about the ground from one side of the plywood, it designated, how SH1. Also, when choosing it looks safe in terms of ecology, emission class. Typically, in the latter case will be acceptable E1, when 100 gram of material is no more 10 grams of formaldehyde. The sheet thickness in this case should not be less than 12 mm.

Dwellings require the purchase of stamps and plywood WBP FC. It is best to choose the first option, because, despite the less moisture, such sheets have high environmental friendliness and lower cost as compared with the PSF class.

Advantages and disadvantages of alignment

alignment plywood floor for subsequent laying laminate - universal way. This suggests the presence of a sufficient number of positive aspects, among which:

- The strength of the material, as well as the degree of water resistance makes it possible to increase the number of the maintenance period, not only the alignment layer, but the flooring.

- to create work smooth surface carried out in a short time and without much effort.

- The result is a truly equal basis, which can be used under any flooring embodiment of floor covering, including laminate onto the concrete floor.

- The excellent properties of heat and soundproofing.

- Acceptable material costs, and minor costs of plywood mounted on a concrete floor.

As for the disadvantages of such material, then first of all it is worth noting the reduction of the distance from floor to ceiling. Some facilities such alignment option, and do not accept from him to have to give up.

preliminaries

To get started is to take care of itself after buying plywood. Do not be amiss to several dry material, special, If purchases are made in the winter season. Be all for about 15-20 days at room temperature.  Because nobody knows, the conditions in which it was prior to purchase. Thereafter, the plywood sheets are processed by various antiseptics.

Because nobody knows, the conditions in which it was prior to purchase. Thereafter, the plywood sheets are processed by various antiseptics.

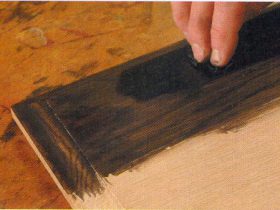

The outer layer can be made more durable. To this end, it is covered with acrylic varnish, which is enough and the two layers. Do not be amiss in the end to cover the stain.

The level of water resistance is also increased to laying on concrete floor under the laminate using putty, which is impregnated sheets. Putty choose the best on the basis of PVA.

Toward the bottom of the concrete floor from the laminate also must meet certain requirements. The most important of them - the perfect evenness. Even before laying the plywood should carefully analyze the existing surface. In the presence of minor protrusions, they can be hidden using the pouring self-leveling compounds. In all other cases will have to exercise pouring of concrete solution. Should pay attention to humidity levels, which will differ depending on the room and its purpose.  After all, in the bathroom or in the kitchen will always be high humidity compared with a bedroom or nursery.

After all, in the bathroom or in the kitchen will always be high humidity compared with a bedroom or nursery.

Barometer - Special for humidity measurement devices can be used, hygrometer etc.. There is a more popular method - to an existing concrete floor plank film of polyethylene. It should be there for three days. The edges of the film at the same time must be very well pressed. Normal humidity level is characterized by the absence of condensate on the inside of our film. Otherwise it is necessary to take measures to reduce the humidity properties of the concrete base. Otherwise, on a sheet of plywood in the future there is a big likelihood of mold and fungi of various kinds. With the latest deal and help fight an antiseptic, which is treated plywood.

cutting plywood

Initially, the veneers are cut into squares, which subsequently are distributed over the entire surface. This is done with a view, to fit each of the sheets to the entire area of the room. Also pay attention to the ledges and niches in a room.

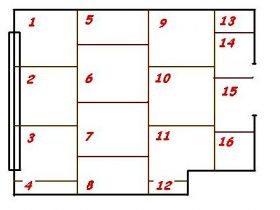

Between the sheets on concrete floor must remain within the damper seal 8-10 mm. It's kind of a gap. To the extreme sheets from the walls should also be a gap, but several more - 15-20 mm.  None of the sheets must not come into contact with each other and with the walls in the room. However, neither the four seam should not converge in one place, offset should be made during installation, as in masonry.

None of the sheets must not come into contact with each other and with the walls in the room. However, neither the four seam should not converge in one place, offset should be made during installation, as in masonry.

When all the sheets on the basis of a concrete floor distributed, It is not superfluous to make their scheme and number each of them. So it will be much easier in the future to make their stacking and mounting on a concrete floor. When cutting is best to stick to the dimensional standards: 1250*1250 mm. But to work with them will be problematic. It will require the experience and skills. In the initial study work on leveling concrete floor under a laminate is best to cut out a sheet of plywood 4 element with the size 600*600 mm. Moreover, it will be possible to easily arrange a required number of stitches in the damper so-called "substrate"Plywood under the laminate onto the concrete floor. On a smaller squares will be less affected by the deformation and external mechanical action, than into squares - "Standards".

When sawing purchased plywood sheets should do everything qualitatively. There should not be torn kroev, and bundles. If they were, but everything was done according to the rules, then most likely purchased substandard plywood. I have to look for the best options for flooring on the concrete floor under the laminate.

Fixing plywood

Often there is one and the same question to align bases under laminate, associated with the, like fasten plywood on concrete floor. Stacking the sheets should be made only on a dry and clean surface. Besides it is necessary to increase the level of waterproofing. Here you can choose a special substrate, which store purchase or use the conventional polyethylene film of appropriate thickness. Flooring film should perform overlapping, connecting seams taped.

Large sheets of plywood efficiently laid directly at the entrance of the room because of a greater load. Further already allocated and prepared sheets vymerennye. Now you can think about, as put plywood on concrete floor.

The paper does not get to do without Punch, whereby the plywood sheets are nailed to the concrete floor under the laminate. It uses a carbide drill. To cap screws do not fall in the plywood, should choose their larger diameter, than the diameter of the drill. Screws are placed in plastic plugs, which are placed in drilled holes. Fixing it must be done not only at the edges of the sheets prepared, but in the central portion thereof. Used in the screws must have a length of three times the, least, something fanernыy letter. So, If the veneer has a thickness 16 mm, screw is used - 50 mm in length. Exactly the same options are available for plug-in dowel.

If even in this case, after mounting excess length of veneer sheets will be found, it can be cut using a jigsaw. When completed all the successive steps, checked quality vtaplivaniya caps screws. It's necessary, that laid laminate It was not damaged during operation. Another very important piece of advice after stacking of plywood onto the concrete floor under a laminate - tapping each sheet. You can use a wooden mallet or prepared bar. The sound must be very uniform, since everything else talks about detachment of the material from the concrete base. Such sheets must be replaced immediately to laminate flooring, to subsequently produce its repair.

There is a subtlety when laying the plywood as a substrate for laminate - the use of glue, which is applied to the substrate before distribution throughout the sheet plane. It is necessary to fill the available space in the presence of a concrete floor irregularities.

Sanding surface

In any case of problem immediately get perfect smooth surface of sheets. To come to him, should generate after laying grinding. It uses a special machine to grind. Usually it is set rough Coated Abrasives.

When the work is completed there should be no burrs, It appeared earlier during the cut sheets of plywood. The grinding process allows the plywood in some cases even eliminate minor differences between the levels of a number of underlying sheets.

Subsequently will only test the quality. To this end, the stacking evenness verified in an area of the room. Using the rail-length rule 2 m, checked vertical drop. If it will not exceed 2 mm, we can say with confidence, that the work has been done is not in vain.

Remain below produce laying laminate on thus prepared substrate, without fear of the consequences. Clearly the work performed and the sequence of actions will lead to long-term operational period of all "pie". In addition, the laminate itself can be matched perfectly with any interior room.

Article written for https://sdelalremont.ru.