Classic wooden floors in the apartment are increasingly overshadowed. This is due to the fact, that there are many different variants of floor covering, among which stands out the laminate. At cost, he even slightly below normal wood. In addition, it is worth noting, that under the laminate can get various kinds of underfloor heating. The main thing to choose the appropriate type of laminate with marks. When hosted basis in the apartment, thus be more comfortable, and even just to stand on the floor with bare feet. The air is heated to the required limit and there is no excess energy.

Types of underfloor heating

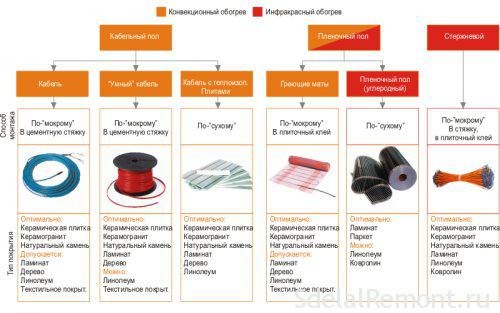

In total there are two options underfloor heating, which in turn are divided into subspecies.

Radiant Floor Heating is performed in several layers: waterproofing layer, laying damping tape on the walls in the room perimeter, insulating layer, installation of heating elements (tubes), concrete screed (in rare cases, gypsum materials). Only when this is done, you can start laminate flooring. Among the benefits is to provide the reliability of the whole structure, safe use without fear of getting burned, lack of dependence on electricity.

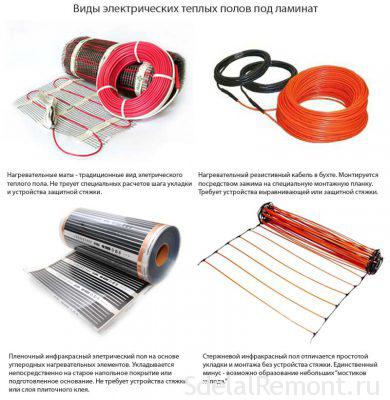

Electric underfloor heating have their own species:

- heating mat.

- Heating cable.

- Infrared Heated floor.

In this case, the electric power is converted into heat, and serves to warm the base floor in the room and further increasing the air temperature in the room. The main feature and unlike water heating - the ability to regulate the temperature level in any range, and put it in, depending on the time of day. In some cases, the laminate can be laid directly on the heating system, by substrate certain thickness. But the laminate in this case must be marked accordingly, that it can be used for underfloor heating.

Popularity for laminate use it film floors. There are two main classes, and which you should pay attention during installation. Budget option - RexVa0501, more expensive premium - HFS0510 and GL-500. If you can not on their own make the right choice and the specific, Help is best to turn to professionals in this area.

Yet each variant of the heating system, which can be mounted indoors, has its own characteristics stacking the laminate on the subfloor. It is at this cost, and stop your eye, to determine, a warm floor under the laminate select.

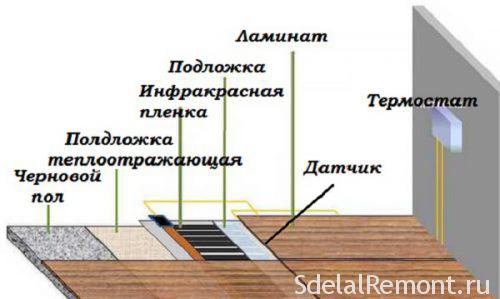

Infrared film

Consumers are increasingly paying attention to film floor due to its easy installation and low cost. In addition, he is best suited for laminate due to uniform heat distribution. When using floor heating system under the laminate will not overheat and damage a floor covering.

It is to provide immediate advantages and disadvantages of infrared heat-insulated floor, which is arranged under the laminate. The main of them - the economic feasibility. Energy consumption reduced to the minimum limit. Even in case of damage to a particular portion of the film floor, he did not fail completely.  Not only will warm a separate area on the floor surface. This is achieved through the parallel sections of the compound. Besides editing process It carried out for a few hours, that will depend on the area of premises.

Not only will warm a separate area on the floor surface. This is achieved through the parallel sections of the compound. Besides editing process It carried out for a few hours, that will depend on the area of premises.

some will say, it makes no sense to arrange the infrared heated floor under the laminate, because he has a very high cost. But his return in just a few years. flooring flooring production can be done in-house.

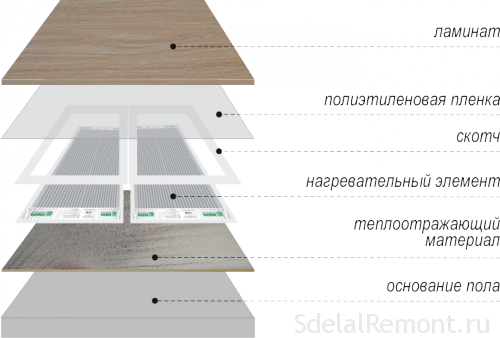

There is a major caveat, which is to create a level surface under the laminate. To achieve a heat reflecting substrate on the basis of aluminum foil made small hole conductors, temperature sensors and contacts. That there were no changes wires, they are fixed by means of a conventional adhesive tape.

To laminate flooring be it on the floor to check the film, then laid material to protect (polyethylene film). The result is a small thickness structure, which has no effect on the distance between the ceiling and the floor in the room. It can even be called the best warm floor under the laminate.

Electrocable

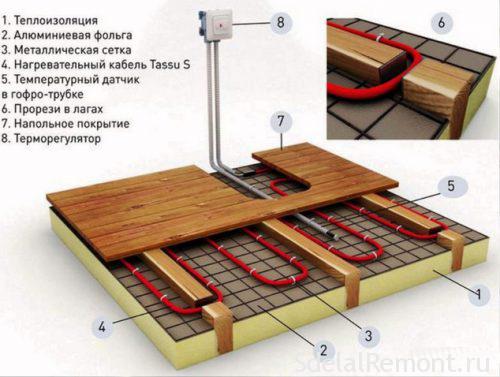

In addition to conventional single-core cable experts recommend using a two-core laminate, facilitates assembly of the entire heating system. It is more suitable for residential premises, because it has a negligible electromagnetic radiation. There is also a version of the self-regulating cable, which is in violation of its integrity cable increases the resistance of, but, Consequently, It does not supply heat to the separate section of the floor.

Mounting laminate flooring on the cable warm performed with pre training base. In some cases, it is covered with a layer of thermal insulation. On top of this structure, the thin coupler is arranged to 3 mm. Do not be amiss to "implement" in construction reinforcing mesh. drying process takes 2-3 day.

Floor screed attached mounting tape, which are fixed to the underfloor heating elements. Coupled with all this is for the basic components - thermoregulator and a temperature sensor heating system. When it tests the functionality of cable underfloor heating, can produce pouring concrete screed certain thickness. It will depend on the requirements of the substrate and the use of the premises. The optimum thickness of casting solution 30-70 mm.

During 28-30 on days Heated floor screed acquires a certain strength and grasped. Include a heating system in this case can not be. The solution should independently get to the condition. You can begin to laminate flooring at the expiration of this period at Heated electric field.

It is worth noting, that laminate floor warm cable similar in process, as with the heating mat. This process also takes less time and is considered to be easier, since the heating cable is fixed in a special grid. Laying laminate can be selected independently depending on preference. It can be parallel or perpendicular to the front door to the room, or even diagonally. The latter option is more challenging, as except docking slats between a trim laminate will carry fragments of the walls. Floor heating under the laminate in this case, has the best performance and efficiency.

rod version

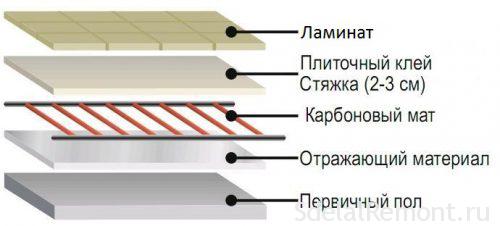

Rod mats have their own characteristics, not only during installation, but when laying laminate.  But if you look at the instructions accurately, the entire process can be completed as soon as possible and on their own.

But if you look at the instructions accurately, the entire process can be completed as soon as possible and on their own.

More attention should be paid is the base, as it aligned, removed all the potholes, cracks, chipped surfaces. Thereafter, the heat-insulating layer made decking. If this has been the primary insulation and, among themselves they should be connected by means of adhesive tape.

Across termomaty area must be evenly distributed. If necessary, make the cut. To the floor, where laid, mats are fastened with adhesive tape mounting. Will only install thermostat and the temperature sensor, which are connected to the mains. Prior to subsequent work system should be tested to establish the possible mounting inaccuracies.

Above all "pie" warm floor screed layer is applied. Self-leveling floors are used to facilitate the solution of the distribution process, with a thickness of up to 20 mm. Moreover, the drying process takes slightly less time, than the standard concrete screed (28 days).

When the layer is completely dry pick strength and, you can think of laminate flooring on floor heating. The process is simple and does not require significant knowledge in a given direction. Depending on the choice of interlocking slats of compounds, performed their stacking and securing to each other. It is important to, to locks have not been damaged, since all lead to poor-quality installation and rapid failure of the laminate.

It is forbidden to carry out work on the installation of underfloor heating rod in the case of high humidity in the room, at a temperature below 0 degrees. Carbon fiber rods are not secured to the base with nails. It hurt them, and they are able to transfer heat to the floor covering. Each segment termomatov should not be more 25 m.

Radiant Floor Heating

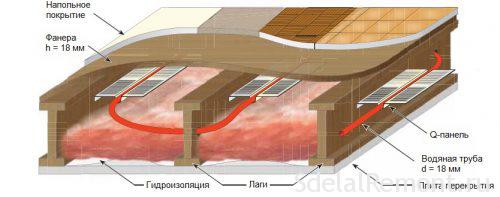

Further embodiment of the electric floor heating exists and water. He is more suitable for private homes, as in apartment buildings it can be used at its founding from the start of construction. Radiant floor represented as heating pipes, which circulates coolant. The pipes are laid under the finishing coating.

No one would recommend to make laying of water floor heating under wooden logs, additional layer and hydro insulation. In case of subsequent laminate flooring on the heat transfer surface is reduced to zero. The best option - concrete screed, which is used widely. Screed does not give the possibility of mechanical damage to the heating pipes, and also contributes to uniform heat distribution over the entire surface.

No one would recommend to make laying of water floor heating under wooden logs, additional layer and hydro insulation. In case of subsequent laminate flooring on the heat transfer surface is reduced to zero. The best option - concrete screed, which is used widely. Screed does not give the possibility of mechanical damage to the heating pipes, and also contributes to uniform heat distribution over the entire surface.

There are several ways, the expense of which is carried out Radiant Floor laminated floor. This can be a parallel or helical distribution of the heating elements of the sections, where it is needed. When the pipes are distributed and connected to the system, can underpour structure screed. In the absence of failures, floor heating is considered to be qualitatively installed.

At the end of the whole process will only produce flooring flooring, namely laminate. The main thing is to choose the specific embodiments, suitable for underfloor heating systems. It must be a corresponding marking, pointing to the possibility of laying an electric or water option heating system.

erroneous opinions

Some experts say, that warm water and laminate floor may not be compatible with each other. But this opinion is considered incorrect for several reasons.

- The main advantage of such a combination - a uniform distribution of heat over the entire surface of the room.

- Minor temperature variations, that it can not adversely affect the floor covering. This increases the operational period of the laminate.

Among the misconceptions can be isolated and then, what Radiant Floor under the laminate can not fully heat the premises in the northern regions of the country. To achieve this quality should produce payment heating system design and select the material for. there are examples, when Novosibirsk buildings in winter at a temperature -40 degrees, the temperature inside the premises did not fall below +20 degrees. Comfortable conditions were created for each tenant.

There will be no flow of water underfloor heating, if you choose a quality pipe. It is not always possible to independently perform quality installation and install all of the technology. To this end, and involved experts. They will shape in time and create high-quality heating system in the room.

The calculation required to make true, and the choice of such a floor covering, as laminate. Even taking into account, he badly misses the warmth, Radiant Floor can cope with its main task and pass the required level of temperature inside the room. The more so because the laminate is selected suitable for underfloor heating system water.

operating rules

Warm floor, regardless of its kind brings about changes in the flooring floor covering. With laminate flooring can warp and lose their original appearance over time.  To avoid this, be mindful of the need in the first days of the heating season, the gradual rise in temperature. The day will be enough to increase the temperature at 5 degrees. This indicates, that the laminate does not tolerate momentary temperature increase and spike. If everything is done according to the rules, its service life will be increased.

To avoid this, be mindful of the need in the first days of the heating season, the gradual rise in temperature. The day will be enough to increase the temperature at 5 degrees. This indicates, that the laminate does not tolerate momentary temperature increase and spike. If everything is done according to the rules, its service life will be increased.

for laminate, Arrange on the system underfloor heating, characterized by marking. The packaging should be the inscription «Warm Wasser», indicating, that the products can be exposed to heat from the heating elements.

Popular models

In conclusion there may be exemplified floor covering, which can be used in the system Infrared floor heating, since this option has the greatest popularity among artists.

Dymsco 0510. It has negligible thickness 275 micrometers and sufficient capacity - 140 W / m2. In the production of unique technology has been applied, composition comprising a polymer film laminate sheet, on which a carbon paste, capable of conducting current. But increasingly this variant as an additional source of heat in the room.

RexVa0810. Designed for virtually any type of premises. Film width is 80 cm. During operation of it is out of print extraneous noise, vibration. The room is warmed evenly and thus minimized energy costs.

HFS0510. The entire length of the film has a homogeneous structure, that allows you to cut at various sites along the length of. This brings its advantages during assembly. For the health of it is completely safe, and further possesses antibacterial effect. If you are using has an excellent efficiency indicators, that reach 98 percent. It is possible to ensure high-quality heating. True and cost at the same time it is almost the most high.

The main thing in the end to decide on the, a laminate better on warm floor. After all, this will depend not only on the quality and beauty of the grounds in the room, but and heating the air in the room. Particular attention is paid to installation technology, having the features according to the use of water or electric underfloor. Article written for https://sdelalremont.ru.