Very often in residential buildings can be faced with excessive audibility, noise transmission. It is worth noting, that most of these sounds, it comes through the floor. As the noise source can act in the flat work carried out, operation of appliances, walking, talk and more. To avoid this, needed soundproofing floor under the screed. This stage in the construction and arrangement of space occupies a weighty significance. He should be given maximum attention, to achieve a positive result.

The choice of material

Prior to the commencement of work, should choose the necessary material. From it will depend not only on the quality of, but also exhibits the properties and quality in service. In the market represented a huge range of. It is important to learn about them as much as possible.

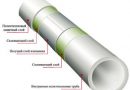

- Mineral wool. It has such qualities, as a low density, and compressive strength. As a result, it gained a high level of sound and thermal insulation. In its structure there are mineral fibers, by generating fusion.

- polystyrene, extruded. He has several high density, than the classical foam. true, due to this it can not be used in floating screed sound insulation layer.

- perlite. This is the usual concrete block and actually perlite. swelling concrete rocks for its production is carried out. They are characterized by the average sound insulation. In more applicable for filling a base screed.

- Styrofoam. Blocks material formed after heating expandable polystyrene beads.

- polyurethane foam.

He protects the little room impact noise. But it has excellent insulating properties.

He protects the little room impact noise. But it has excellent insulating properties. - Fibroplity.

- vermiculite. It has increased resistance to degradation, thereby can easily be pressed. He is not subject to rotting process, capable of withstanding elevated temperatures.

- cellular concrete. It is used rarely. This is due to sensitivity to high humidity, as well as creating sufficient load on the slab.

rules laying

Before the beginning of work is determined by the material. His main quality is to be compressibility. It is characterized by the difference between the plate thickness and thickness under load. The softer the material used itself, the better will be its sound insulation properties.  Noise will not spread to other buildings design. But too soft, he should not be, as in this case, the screed will sink.

Noise will not spread to other buildings design. But too soft, he should not be, as in this case, the screed will sink.

When a structure in several layers, to the basis You must be located more soft mats for soundproofing. Then lay a stronger compression. We can not forget about the Extension seams. Underlying seams should be identical in location overlying. They should overlap each other. All layer must eventually be covered with a film of polyethylene to create waterproofing layer.

The layer thickness of the future are included all the elements, including self overlap, made screed floor.

arrangement of technology

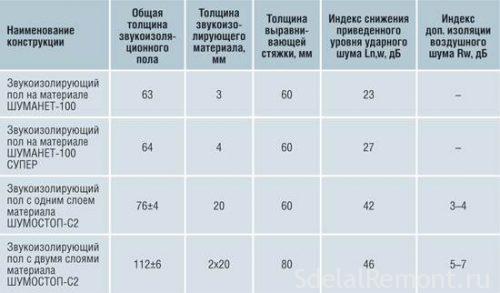

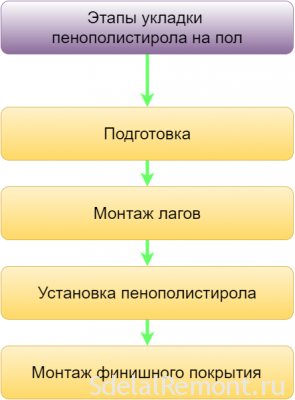

Considering the technology itself to create a screed in the apartment soundproofing, best to take into account the material, as "Shumanet". All work can be done independently of any person. No experience in this will not have. There workflow technology, which comprises the following steps:

- Removing the floor screed. This allows you to subsequently make a quality floor structure. In addition, at this stage, you can find other surface defects and having the entire layer.

- preliminaries. It includes a series of actions, necessary layers, processing respective materials. It is worth noting, that the sound insulation gender in the apartment under the screed Shumanet is virtually no activities and the installation is carried out in the shortest possible time.

- installation. To use only necessary to roll the material along the plates. For joining strips together using an adhesive tape construction. You should definitely make an overlap on the wall thickness of future floor screed.

Substrate preparation

This step requires care and labor costs. After floor disassembly to overlap, removed all the available waste, mud, even the dust. If you do not, It will then create problems with the floor insulation layer. Moreover, the service life will increase considerably, if you do everything qualitatively. In certain cases it is possible to arrange additional leveling the subfloor to the following activities. After that is laid on the surface of polyethylene film. I feel sorry for her in any case be. floor plate must be completely covered her without gaps. This will ensure that, the moisture of future ties will not fall to the neighbors.

isolation device

The paper used material, which has been selected for the sound insulation dry screed. This layer is arranged on the film Laid. It is very important additional layer of reinforcement. In its capacity as a special metal mesh may be used or other modern means, such as, fibrovolokno. She would not let drenched in the process of drying screed crack.

You can buy ready-made kits for soundproofing floor screed in the apartment. They can only spread out on the surface of certain layers, each of which covers a distance subsequent to vymerennoe.

There are several different ways arrange screed soundproofed. All will depend on the embodiment and the desired result. This can floating concrete coating, dry floor screed, the creation of modular flooring. Each insulation layer has features.

Regardless of the screed process soundproofed, skirting to complete the work should be attached to only one surface. It can be wall, floor. Under the plinth is laid rubber pad. If you use nails, they can serve as a sound conductor.

screed

The final stage is to fill the entire process screed floor to the substrate. For this purpose initially set beacons on the perimeter of the room. They will serve as the basis for the quality of the finished casting solution. Lighthouses are best used on adjustable supports. labor costs in this case will be minimized.

To the solution should be prepared place. The setting should not be spoiled. It is not superfluous to use the power tool or invite Assistant. Much will depend on the thickness of the screed. That it is not quickly cracked, it is best to choose a minimum thickness in 50 mm. But in any case it is impossible to start operation of the floor until, until the filled solution is not completely dry. Moreover, after the cracked, screed starts damaged isolate. The room will again pronimat background noise and sounds. That is, all the work will come to nothing.

Practical Tips

To dry the floor insulation under screed gives the room quiet, We must be carried out some very important tips. The process must not deviate in the workflow and apply only quality material to work.

A better level of sound insulation provides a softer material. But very soft ties will contribute to subsidence. Choose insulator should be depending on the compressibility module, which has the indexing "Wed". Under load for premises it should not be changed by the thickness of no more than 5 mm. Otherwise, the screed will be destroyed and deformed.

Stiffer materials are stacked in the device of the sandwich structure. At the bottom are placed soft ware. In this case, much depends on the slab, selecting floor covering. They also have an effect on the absorption of noise, which may come into the room.

screed on top of such material, as mineral wool is better to perform after applying a plywood sheet. He thus has to be waterproof. This is due to high softness of insulating material.

If these comply with all the requirements for soundproofing layer laying under the screed layer, you will eventually get a really high-quality design. It will only have to lay flooring and enjoy the silence in the room.