The concrete surface is treated with various preparations reliability. They all have numerous features and functions, providing certain benefits. Of particular interest is the rubber paint concrete floor. It can be applied to a whole any subfloor. But not everyone knows about the existence of such material, since he appeared relatively recently.

concept

On the market there is a huge range of paint products. But not all of the bottom of the concrete floor provides high quality and strength. Formulations for this improved, they are added to various components. Rubber paint has super elasticity. But this does not matter dissolved rubber or liquid, which is composed of paint. All is, that after complete drying of the material formed on the surface of the polymer film.  It is able to expand with an increase in temperature inside and compressed by lowering the. In such a case will not appear on the surface of cracks and chips. That's what they differ markedly from the oil paints.

It is able to expand with an increase in temperature inside and compressed by lowering the. In such a case will not appear on the surface of cracks and chips. That's what they differ markedly from the oil paints.

The rubber-based paints - aqueous dispersion composition with acrylate polymers. There are no solvents, even organic, as well as other substances, may harm human health. For saturated colors in paint composition there pigment. In addition, the market represented a huge range of products, which will appeal even to the true connoisseur and demanding customers.

After applying the paint onto the substrate and complete drying, the surface becomes dull. If you feel it, it will remind the gravel with a small fraction. It is important when applying, that has been completely respected technology. Otherwise, no positive results have been obtained will not work. It is this version, and it will be excellent for concrete floors.

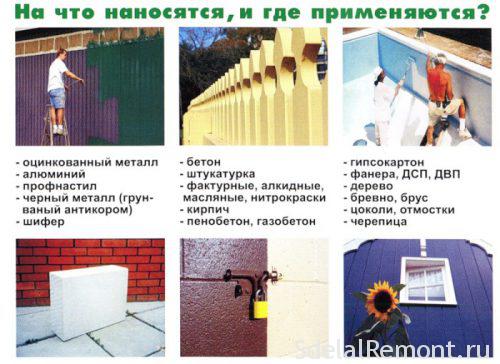

With regard to the application, then it is often used in sports facilities, as well as in industrial areas. The same applies to the underground parking, and more specifically from entering into them. As for the home environment, it is suitable polymeric dye concrete floor bathrooms, on balconies, veranda, balconies and other.

properties

Rubber paint for concrete floor has its popularity and widespread use due to the large number of properties and qualities, among which are the most basic:

- wear resistance. It is able to serve for a long time.

- Shock resistance, water resistance, confrontation slip.

- ecological purity.

- odorless, in the process of applying, and after drying.

- Not available in organic solvents.

This type of coating for concrete floor It is used as a base for dedusting. While maintaining the same temperature in a room at a 20 degrees, dry paint capable less than one hour. You can choose different colors, which will be able to fit into any home decor.

In the operation of the base polymer paint protects the concrete floor against mechanical and other external damage, traffic load.

classification of paints

Not only rubber paint can seize the advantage in the field of application to concrete floors. There are other types, It has both advantages, and disadvantages:

- Acrylic paints. The basis of this material - acrylic resin with polymers. When applying such a concrete floor is protected from external influences, excessive pressure, corrosion. It further has the following properties waterproofing. The paint is perfect for use on the terrace, in cellars and garages. dyeing process does not require special knowledge, but very quickly dries up after covering a concrete floor. At a cost of very attractive, due to which demand in the construction market. Most of the work may be performed using a conventional roller. All other remote sites are covered with a brush. In exceptional cases, apply sprays. Even after complete drying of the ink should be given at least twenty-four hours, so that she could gain protection functions.

- epoxy paints. Here are composed of two main components - resin and hardener. They have to be mixed prior to application to direct floor surface. Concrete properties are improved, and besides, it becomes protected from erosion. Through the use of epoxy paints, concrete density increases approximately 2-3 fold. Besides preventing cracking and chipping. If water-based paint, it can even be applied to damp concrete after pouring. But it should be remembered, that once added to the hardener, there are only two hours, to be applied to the surface, otherwise they dry up. The main drawback - high cost, that some and repels.

Benefits rubber paints

Experts nevertheless recommend that you stop your eyes on it for rubber paints concrete floors due to the large number of positive qualities. Among the advantages are the following the most basic:

- Easy application to the surface.

- High level of flexibility, whereby the possible appearance on the surface of the dried chips and cracks. She is in service not peel off.

- It has no smell, during use does not release into the environment of hazardous substances.

- The coating is not blown up or come off due to the excellent adhesion.

- Concrete with the paint, "breathing". This indicates good water vapor permeability.

- During operation, the paint does not slip, not wiped.

- It can be used indoors, and on the street. Fluctuations of ambient temperature it is not afraid.

- waterproofing function.

- Delivers ultraviolet rays.

Another important advantage - the flexibility of the coating. And it significantly distinguishes it from other paint formulations. No compression or stretching of "rubber" layer is not afraid.

Very often, these formulations are used for getting rid of emerged defects of the concrete base. After filling the grooves and paint chips, composition fills and penetrates deep inside. Floor surface becomes smooth and without damage. Subsequently, even the moisture will be able to impact negatively on the base.

As for durability, here means not only operating for more than a decade, but also the preservation of original appearance and color.

Apply paint composition on a concrete foundation in thin layers. The entire area, in this way, It must be passed 2-3 fold. But it is worth remembering, that the thick layer is not allowed as a result.

Application area

Due to the large number of positive qualities of rubber paint, and a list of properties and qualities, area of application is very extensive. In addition to rooms with high humidity, apply makeup, including on the street, regardless of the temperature indicators. It is very difficult to abrade even in the garage underneath the vehicle or in places of work. It will have to make a large amount of effort.

Basically such paints are suitable for installations where external influence - industrial sites, building sites, Sport halls, as well as the parking spaces.

preliminaries

Paints and coatings must be applied solely to the prepared substrate. The surface must be removed to the maximum dust and debris.  It does not save even otherwise, and the high degree of adhesion to the base. While rapping concrete You can find weak spots, from which should get rid of mandatory. For this produced a partial heavy or surface repairs. If there are places with old paint coating, it should be clean. Do not be amiss to handle the protected areas of concrete primer. It will contribute to strengthening the base, and "binding" dust. grinding and painted concrete floor It does not take a lot of time, but it requires attention.

It does not save even otherwise, and the high degree of adhesion to the base. While rapping concrete You can find weak spots, from which should get rid of mandatory. For this produced a partial heavy or surface repairs. If there are places with old paint coating, it should be clean. Do not be amiss to handle the protected areas of concrete primer. It will contribute to strengthening the base, and "binding" dust. grinding and painted concrete floor It does not take a lot of time, but it requires attention.

Very often before applying the paint onto the surface of water was added thereto. But experts are categorically against such action. Suffice it carefully stir.

If work is carried out in the same room, it is enough to be a construction roller. In other cases, most of the work is a gun, which allows to reduce the time period needed. There are requirements and temperature conditions. During the application it should not fall below +5 degrees.

application Procedure

Painting gender rubber paint is carried out using conventional tools. Only in exceptional cases have to work with special means, are purchased or taken in rent. But it is mainly concerned with industrial facilities.

When the surface is fully prepared for the application, can be taken into the hands of paint and begin to apply evenly over the entire area in the room. The number of layers is usually taken 2-3. All will depend on the base and conditions. All subsequent layers after the first should be applied only when complete drying of the previous. Otherwise, you can not count on the good qualities and displays all properties.

Everybody knows, the paint dries in no time. But this should be careful in terms of cleaning and wiping surfaces with a damp cloth. This can only be done one week after the complete drying of the material. Claimed hardness is dialed and you can not worry about injury.