laminate stacking technology to the floor with their hands is not too much difficulty. But, after reviewing all the details, You do not have to spend money on professional services. mounting process will depend on the type and interlocks, quality training grounds, and placing the selected method laminate. That will have a comfortable cover, which only give beauty throughout the interior and the appearance of the premises.

Select a

For the laminate is no difference in the, What exactly is underneath ground. It can be a concrete screed, wooden floor, Another embodiment of the floor covering.  There should be observed only one very important feature - the base must be perfectly smooth and durable.

There should be observed only one very important feature - the base must be perfectly smooth and durable.

For wooden and concrete floor also has certain requirements, that you should know. The concrete surface for the perfect alignment It is performed by pouring the prepared solution. In order to achieve maximal alignment effect, nessesary to use self-leveling mixture, capable hide elevation and surface defects existing.

More problems usually arise with wooden base, which loses its appearance, can rot through and give the soil life of various microorganisms. Often, there are scripts when walking on such floor. From them can be removed by screwing the individual elements of wood or residence to their lags.  But this method does not always have efficiency. In some cases it is easier to make a complete replacement of individual sections of the wooden floor, or get rid of it all. In the latter case, the concrete screed according to the rules under the laminate in compliance with the mixing ratio of the main components.

But this method does not always have efficiency. In some cases it is easier to make a complete replacement of individual sections of the wooden floor, or get rid of it all. In the latter case, the concrete screed according to the rules under the laminate in compliance with the mixing ratio of the main components.

As the base, under the laminate and old linoleum can be used, from which you do not want to get rid. This has its advantages, as it acquires additional sound insulation qualities. However, this variant may be used only in the event, if the ground under the linoleum really smooth and wherein the floor covering itself in excellent condition (does not crumble, not falling apart, etc.).

Instruments

installation of laminate on the floor with their hands can not do without a certain set of tools. These include fashionable:

- Hammer.

- Knife.

- Pencil.

- jigsaws.

It can even be called the basic tools, without which it is impossible to ignore. Additionally, use a piece of wood or dobojnika, wedges and a special bracket, which can be replaced montazhki. Dobojnika used as a tool, at which knock will quality for joining the individual elements of the laminate together. It is strictly forbidden to make beats from the laminate, as this not only will disable existing interlocks, but do not allow to produce a further mount laminate.

Dobojnika with wedges and with a bracket can be purchased in one package. This set is found everywhere, where the laminate is carried out sale. It is much easier and more profitable, than to find and buy everything separately. This all together will allow us to answer the question of whether, as laying laminate on the floor efficiently and quickly.

Recommendations prior to installation

installation It should begin with the study of important rules, which is to adhere to:

- Laminate after purchase has to lie down in the room, where its subsequent installation will. In this case, he gets used to the microclimate, and will not be deformed, even slightly after the flooring on the floor. This is the first step towards, how to put laminate flooring.

- You can visually hide the joints between the existing laminate elements. For this laying floor covering It should be carried out exclusively perpendicular to the existing room window. Incident light will hide possible drawbacks when laying.

- Before laying substrate base is swept and cleaned using a vacuum cleaner of the construction. Under it should not even be a small trash, since all this has a negative impact on the state of the material during operation. In addition, no harm will be laid and a polyethylene film before, as lay laminate on the floor with their hands.

Laying the substrate

When the base is under the laminate carefully prepared, you can begin to work, directly related to laying floor covering on wooden or concrete surface. The first is to take care of the flooring substrate. To know, how to put laminate flooring, to support the selection should be taken responsibly. After all of its quality will depend on the durability of the floor covering during operation, as well as the manifestation of all its qualities and properties.

pad It can be a budget, and expensive. By the latest version include the production of cork, and dual substrate, which is gaining interest and popularity among artists, seeking advice on how, how to lay laminate flooring.

If the laminate itself is not expensive, something few people pay attention to the above support options. In this case, greater interest is the production of polyethylene foam, Styrofoam and combination options.

Padding under the laminate It is intended to compensate for a person steps on the floor covering, as well as any external influence. Also stored in the integrity interlocks, presence of which will depend on the use and durability of the floor covering. The substrate may easily hide minor surface defects, but it is not necessary to acquire a very thick material. The standard thickness of the substrate under the laminate is sufficient to 2-3 mm.

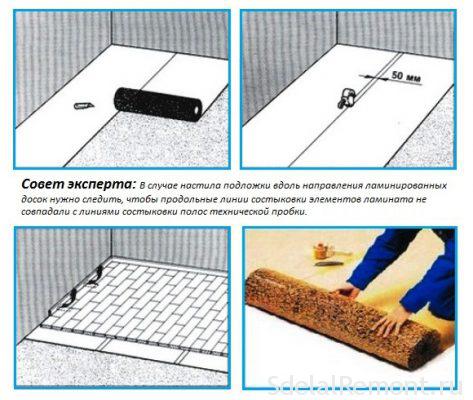

The process of laying the substrate did not cause difficulties even for beginners. There need only be aware of certain rules and requirements, like putting laminate flooring with your own hands. One can never overlap plank substrate. It is unacceptable. Stacking is carried out under the laminate material joint to joint, after which the latter are glued further tape. These actions are necessary to conceal the possible gaps between the rows or manicured substrate elements.

Laying process does not differ from the roll or sheet product. Only reduced installation work and the time frame on the substrate under the flooring laminate. The most simple is different roll, which can Rastel from wall to wall and begin laying the subsequent row.

Some laminate manufacturers present their recommendations on the choice of a particular option pads under the form of floor covering. This is what you should pay attention if you want to get a quality outcome.

The need for polyethylene film

When installing a laminate floor on each budding artist arises many questions, associated with the components of the "pie".  Experts say that, a substrate that has a need for laying polyethylene film on the substrate. And there is a certain truthful steps.

Experts say that, a substrate that has a need for laying polyethylene film on the substrate. And there is a certain truthful steps.

With downstream floors, especially if it is not heated basements, to the base floor receives a large amount of moisture and dampness. that protect flooring from its negative effects and uses of polyethylene film. It is also needed in case of emergency laying laminate onto a concrete surface, has not had time to dry properly. Consequently, the main function is used when mounting the film - protecting against high humidity level floor covering. It tells all, how to laying laminate sex.

self-laying

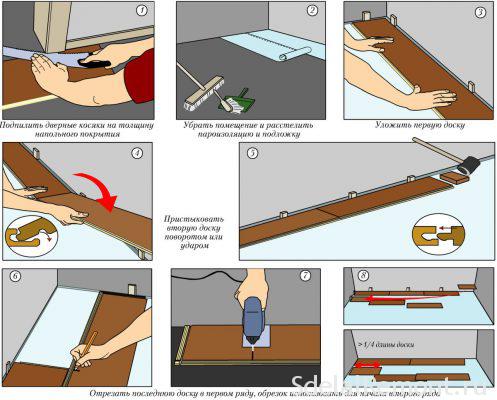

A large number of artists concerned with one very important question - as himself lay laminate sex. Start of work on laying laminate on its own on the floor - from the light source, i.e, from the existing window opening. Initially performed construction of the first slats in the corner by the window. On the side walls of the room are exhibited special wedges, you need to create a kind of gap. In the future, it will be hidden by means of plinths. No clearance can not be dispensed, as in the operation of the laminate tends to expand. They serve to maintain the integrity of the slats and the locking connection.

The end parts of the slats laminate There are special slots, in which follow-up and should fit board flooring. So zadelvaetsya first row up to wall. At the edge of the wall produced drank the required size of the whole board. To make it possible to use the jigsaw or hacksaw.

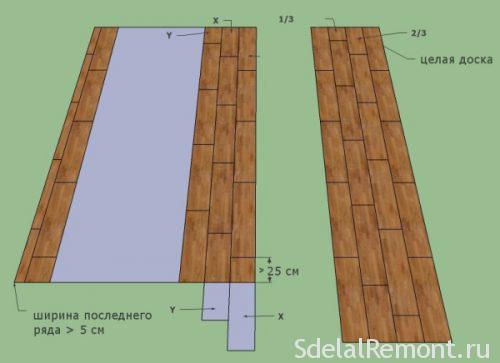

The second row will start with the piece of laminate boards, which remained after the installation of the first row. But there is one important requirement, which is, that this piece must have a length of at least 30 cm or less 1/3 the total length of the sipe whole. If this is not met, the cut half of the entire board and laid at the beginning of the second row.

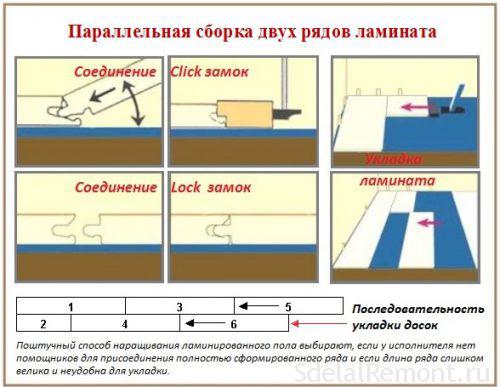

Initially, the second row is not connected to the first tool joint. It is necessary to assemble a complete range of up-to-wall, followed by slightly raising, is put into the lock and latches. Hammer used here only in exceptional cases, to remove the strain on those parts, where locks are not logged in densely one another. It is important initially to put a block of wood, and only then to strike. Otherwise easily encounter damage laminate, that requires replacement.

That's what goes on laying laminate with his hands on all the planes in the room. Upon reaching the opposite wall in the room, have to make the cut laminate boards are not across, and along the. There should be no difficulties, important to leave a gap between ulodennym flooring and walls 10-15 mm.

diagonal arrangement

More problems may occur if the laminate stacking their hands on the floor on the diagonal spaces. This option allows to visually enlarge the space in the room. But in this case it is necessary to be ready to, that will have to spend a bit more material to work because of the increased amount of waste.  When choosing and buying laminate, to the area of the whole premises will have to add 7-9%, to be sure, that will not distract from work to buy the missing amount.

When choosing and buying laminate, to the area of the whole premises will have to add 7-9%, to be sure, that will not distract from work to buy the missing amount.

All work on the preparation of the base is no different. There only needs to pull the fishing line, thread from the window at an angle 45 degrees with respect to the wall. It will serve as a benchmark for subsequent laminate flooring on the floor with their hands.

laying made as follows:

At the first floor covering strip turning angles, sticking angle 45 degrees. Thereafter it is placed in a corner in a room, exposed to wedges and as a thermal gap in 10-15 mm. After this, take two more bands, are joined together and applied so, that the resulting seam is in the middle of the first strip. The cut edge in 45 degrees should fall to the wall leaving a gap in the compulsory 10-15 mm.

Further process faster for the time frame, since there is a greater amount of whole slat at laying on the floor. It is worth noting, that it is easier to initially distribute them across the surface of the base, then do already circumcision boards and splicing them to the walls.

All these actions will help get rid of the "celebrations" of the walls, when they vary the joints between the sections of each subsequent series. That will have a really high quality inlaid flooring, which perfectly complement any decor in the room.

When the laying laminate on the floor in any room it is very important to comply with all points of work. Tips from manufacturers, as well as experienced artists will avoid possible problems during operation.