Any subfloor must have not only a quality coating for protection from external manifestations, but also give the entire room an aesthetic appearance. When laying laminate and choosing the concrete surface will play the role of all components of the "pie", so exactly how it will serve as a support, and perform many important functions. It was her choice should be approached with great responsibility when visiting DIY stores.

support functions

As a substrate material, nastilaemыy under laminate, It performs a number of very important functions, among which are the main:

- Creature smooth surface. Minor defects in the form of a base height differences can be hidden by using the substrate. It is very important for such a floor covering, as laminate. But it is necessary to be careful in case, if someone thinks, that even substantial differences will be invisible under the thick backing. In this case at the junctions of the substrate at a concrete floor will sag, thereby creating the danger of damage to the laminate, arranged on the concrete surface.

- Sound-proof quality. In the absence of a substrate for laminate concrete floor, It will be heard every step. Even a thin layer of a 3 mm will help avoid such troubles. It is worth noting, that there are certain classes of laminate (32 and 33), which have been built substrate. Stacking produce such a material is much more pleasant and less time spent.

- Thermal conductivity. This quality speaks about the need to correct the substrate of choice, if arranged underfloor heating system. There have to pay attention to the specific embodiments of the material under laminate.

- Protection against moisture. Concrete surface even after drying tends to isolate itself from a specific level of humidity. This will have an adverse impact on laminate, because it is very afraid of high humidity. Built properly padded protect flooring from swelling and absorbing excess moisture.

Right choice

In any store you can find a huge amount of support options under the laminate onto the concrete floor. But it is necessary to be careful when it is selected.  First, we should pay attention to the condition of the subfloor. At sufficiently smooth floor will suffice priobrestiioonkuyu substrate 2 mm. In the presence of minor base errors sex laminate, already sold 3 mm substrate. Thick material should not buy, because in combination with the laminate in 8-9 mm, It will be reduced significantly the distance from floor to ceiling.

First, we should pay attention to the condition of the subfloor. At sufficiently smooth floor will suffice priobrestiioonkuyu substrate 2 mm. In the presence of minor base errors sex laminate, already sold 3 mm substrate. Thick material should not buy, because in combination with the laminate in 8-9 mm, It will be reduced significantly the distance from floor to ceiling.

some deem, it should acquire and laminate substrate and from the same manufacturer. Such requirements do not impose even the experts. These are not materials, which have an excellent combination of from one manufacturer. They vazimozamenyaemy and almost all have a similar structure and qualities list. Consider how to choose a substrate for laminate and a material better.

It makes no sense to buy support from the same manufacturer, which released itself flooring - substrate of any manufacturer are fully interchangeable.

What is the substrate

The substrate for the laminate need for floating floor technology. This is due to several factors, which we'll talk.

Soundproofing. If litter under the laminate is not being used, each step is given a resounding thud. Having an even layer of soft hide small noises, friction (cm. article about the soundproofing apartment).

sometimes 33 and 32 class meets laminate substrate built: the back side is already bonded insulation layer. To stack the material more convenient, than the usual, but because of the difficult technology of production cost increases significantly.

surface leveling. Another function of the substrate - leveling small irregularities. This is very important when laying laminate, because the durability of the locks depends on the flatness of the base. according to the technology, permissible differential floor should be no more 2 mm 1 m. However, too large thickness of the substrate under the laminate likely interfere hide unevenness, because then at the joints while walking it will sag. That the seams do not have spread in six months, floor surface thoroughly prepared prior to laying coverings (cm. article about laying laminate on a wooden floor.

Vlagoizolyatsiya. Laminate made of pressed paper, so even water-resistant model does not need to be at increased humidity, otherwise the panel swell. Laying substrate under the laminate provides additional protection from moisture from the concrete floor. For this reason, before the deck coating is better to wait at least a month after the concrete screed.

As ties readiness test can be put on the floor the night polyethylene. In the morning on the concrete should not sweat.

Thermal conductivity. Typical substrate for laminate, installed under floor heating, reducing its performance, since himself laminate, and the substrate material have good thermal insulation properties. For underfloor heating there is a special substrate, about which we wrote in this article. Also we recommend that you read the article about installing the water warm floor with their hands, which describes a process of assembling a wood concrete foundation and with the further finish laminate.

The thickness of the substrate

It is worth remembering, that the thickness of the substrate should be selected under the laminate. If the lining is too thick, a thin laminate, it is likely that the service life is reduced by several times, because any substrate - a relatively soft material, and therefore, the entire burden will fall on the laminate. Over time, it may lose the form, and even crack. To avoid errors, better acquire exactly the thickness of the substrate, which is recommended by the manufacturer of your chosen laminate.

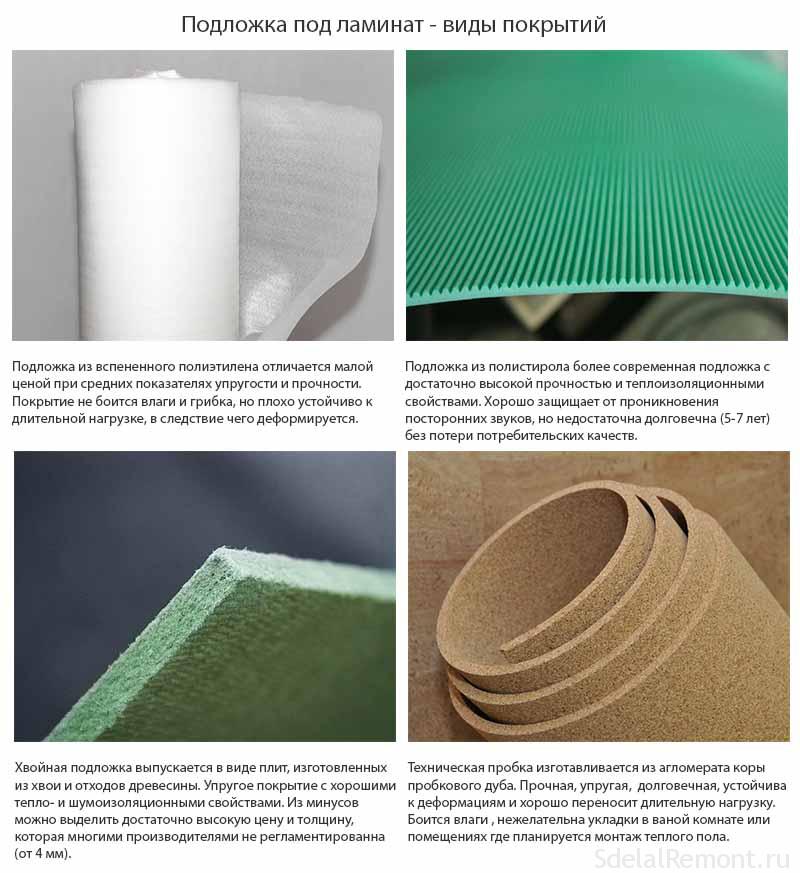

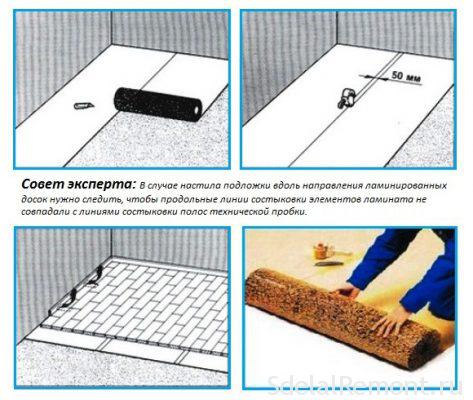

cork

Despite, that the plug is among the natural materials, for it is not peculiar manifestation of microbial life (fungus, mold). You can find support, not only in rolls, but the sheets, which to some extent makes it easier editing process. For a long period of use of such a substrate, it will remain unchanged, and leave the shape and size of the original version.

Due to the high cost of cork backing, it is not in great demand, especially if a cheap flooring selected. It should also be noted, and one important drawback of this material - water permeability. In the course of the maintenance period, below the substrate can accumulate condensate.

The materials can be combined with each other, with the result that there was a bitumen-cork underlay. It is executed on the basis of Kraft paper with the addition of a certain amount of bitumen. All this is in the process of production is covered by a layer of small balsa wood chips. As a result, the resulting products eliminates the main disadvantages of cork itself - no condensation occurs during operation under substrate laminate concrete floor. The material breathes, It is moisture and also able to reduce the sound level. The cost remains at a high level, it is not suitable for budget options laminate.

dignity: environmentally friendly, almost not compressed under loads, durable, improves sound- and insulating qualities of the laminate, better than the other coating hides uneven rough base.

disadvantages: afraid of water, not recommended for installation of floor heating, high price.

foam

The most demanded material pads - foam. This is largely due to its low cost.  But, in spite of this, pad under concrete floor It has many positive qualities, among which may be mentioned:

But, in spite of this, pad under concrete floor It has many positive qualities, among which may be mentioned:

- thermal insulation.

- Humidity resistance.

- Lack of exposure to rodent damage, and also the appearance of various microorganisms.

If combined with a polyethylene foam backing compositions foiled, it is perfect for laminate embedded in the infrared heated floor. But the concrete surface is, abandon the neighborhood of important components.

Like any other foam material has certain disadvantages. The main thing to note, he made of synthetics. During the operational period, it does not guarantee the original appearance, as it has a sinking property under the influence of external loads.

Like any other foam material has certain disadvantages. The main thing to note, he made of synthetics. During the operational period, it does not guarantee the original appearance, as it has a sinking property under the influence of external loads.

If you use this pad in dry conditions, have premises likely impact current owners. This is due to the accumulation of static electricity. Each of these items suggests, that consideration should be, Is it worth saving on this material under the laminate onto the concrete floor,

Benefits:

- it is moisture resistant.

- Not afraid of mold, fungus, not like rodents.

- It has good sound insulation properties.

- To lay it quite easily, combining conventional stationery scotch, at the same time you can do almost without waste.

- Sometimes it produced duplicated with aluminum foil, so that it can reflect the thermal radiation.

- Izolon well smoothes on the basis of irregularities.

- Impervious to many chemicals.

disadvantages:

- short-lived. After one or two years, it loses its shape, elasticity and stops working as a damper, depriving laminate support.

- If izolon long kept before being sold in direct sunlight, it is subjected to destruction and scatters dust.

- A serious drawback of polyethylene foam is its ability to accumulate static electricity, Therefore, in dry conditions when the heating laminate winter often "charges" people sensitive electrical discharges.

So do not particularly chase cheapness and save at God knows what a big amount, risking comfort. In this case, the choice remains: buy imported polyethylene foam, eg, Quickstep from the company, or prefer him home, which costs four times less.

Hvoynati pad

Technology does not stand still, and manufacturers are constantly offer new product range, which can be used as the substrate under laminate concrete floor. Among these new products can be identified coniferous tiles. The stores to find such products would be very problematic. This is due to the high cost of. Among the manufacturers of most common conifer substrate under a laminate floor from Izoplat.

Material wholly different ecological. It has excellent water vapor permeability, which eliminates the potential greenhouse effect. But here's the strength properties are inferior cork backing. Also pay attention to the thickness of the substrate from the needles. it is 4-5 mm, several not fit the requirements, which manufacturers impose for laying laminate concrete floor. In addition, the substrate itself installation is diagonal to the walls in the room.

Expanded polystyrene

Another popular material for the substrate under the laminate on the concrete floor - polystyrene. The substrate for laminate flooring on concrete able to cope with the available irregularities on the floor surface in the room, and at the same time during the operation very well cope with the stresses arising. In its composition substrate has a large amount of air, which makes it more effective than the other embodiments.

Moisture best substrate for laminate flooring on concrete, made of styrofoam, It does not pass, and has excellent zvukopoglaschayuschimi qualities. During walking there is comfort and no outside noise. In comparison with the polyethylene foam, this material is much better retains its original appearance iiaamoe main shape and size.

Among the most sought-after and popular substrate manufacturers under the laminate onto the concrete floor can be identified and Arbiton Izoshum. They are recommended by many experts, which has long been carrying out work for laying laminate in different rooms.

Benefits: The "izoshuma" excellent soundproofing and heat insulation characteristics. They are willing to use the owners of private houses for laying laminate, because they are particularly interested in heat savings. In the apartments of apartment buildings will also be valuable insulating properties "izoshuma", since it effectively absorbs the impact force to the sounds 27 dB.

After it is not a long time walking on expanded polystyrene compacted like a rickety foamed polyethylene, because it has a more dense structure.

Thanks to these qualities, he is perfect for use in high-load areas.

disadvantages: If at first for some quality it surpasses even the famous roll stopper, then a few years later these qualities "blown away", i.e, we can talk about the lack of durability of the material.

In case of fire and ignition weight polystyrene allocates toxic compounds, thus also contributes to the rapid spread of flame.

Absorbing pad for floor covering Vibroflor

A thin substrate of polyester fiber preprocessing. Used as a vibro- and sound insulating pads in the device "floating floors", bases under laminate

Appointment for final flooring.

Vibroflor consists of a polyester fiber containing no preprocessing any binder additives, It is making it absolutely safe for human. To reduce the impact noise level Vibroflor recommended for use in building structures as vibro- and sound insulating pads in the device "floating floors" of light materials, such, as laminate, flooring, etc.. There is also a positive feedback on Vibroflore, It is used together with the panels Sonoplat, as a separating layer, which levels the surface and reduces the transfer of vibration.

Vibroflor - a versatile material with vibroacoustic high efficiency at relatively low cost. Vibroflor used as an elastic gasket at the device of "floating floors" of light materials (laminate, flooring) and "floating" screeds, to reduce the impact noise level under the slab floors in residential and public buildings of any purpose.

combined options

Some materials have certain disadvantages, that and lead them to the worst position when buying. To avoid this, manufacturers make individual components of the combination in one, to create a truly effective substrate for laminate onto the concrete floor.

It may be noted that option, as a combination of polystyrene and polyethylene. The huge popularity here belongs to product Tupleks, wherein between two layers of polyethylene placed polystyrene beads.

The thickness of such pads is 3 mm and is realized in the form of rolls.  Among the basic qualities of the resulting combination may be mentioned ventilation entire room, where the laminate is laid on the concrete surface. Inside moisture misses due topsheet. But while it is supplied to the inside of the granules available through the bottom substrate layer. In the upper layer also has the technological gaps, through which the moisture of the granules falls outside.

Among the basic qualities of the resulting combination may be mentioned ventilation entire room, where the laminate is laid on the concrete surface. Inside moisture misses due topsheet. But while it is supplied to the inside of the granules available through the bottom substrate layer. In the upper layer also has the technological gaps, through which the moisture of the granules falls outside.

The choice of thickness polkladki

Acceptable thickness of the substrate under the laminate is in the range 2-5 mm (for cork backing - from 1,8 mm.) The optimum thickness - 3 mm. The substrate thinner may be used with a thin laminate and stacked on the base with minimal flaws. The substrate of greater thickness is typically used with a thick heavy-duty laminate, solely on the manufacturer's recommendations. thicker than 3 mm has a substrate of dense, slightly rumpled and virtually no caking during use materials, usually a sheet substrate. The substrate may only smooth the fine irregularities in the substrate, instead unacceptable leveling the subfloor with significant differences of heights to try to solve the problem of increasing the thickness of the substrate.

The thickness of the substrate is not accidentally soft limit 3 millimeters, and to increase its, putting the substrate in several layers, In no case can not be. The fact, it is wrinkled and caked in service, and over time, the thickness may be reduced by half. In this way, a laminate is formed under vacuum, backlash, and the greater the thickness of the substrate, the more it will play. A laminate voids under a very negative impact on the Click connection, lead to their premature failure.

As a result of the substrate embodiments discussed, can say that, that the final choice will depend primarily on the good quality subfloors indoors, as well as the financial component of the issue. Indeed, natural materials will cost good money. But it is better to buy quality products, than later to spend money on rework and rework. Concerning Rovnosti surface, in some cases there are valid standards, which allows to hide the substrate for laminate. But it is best to carry out activities on their own.

If done efficiently and select the appropriate substrate at a better laminate concrete floor, the final design will last for at least 10 years old. It is also worth noting, that during the operational period will not have to think about making repairs subfloor, in which besides it is very pleasant to walk, feeling comfortable with each step.

Article written for https://sdelalremont.ru.

https://www.youtube.com/watch?time_continue=1&v = cuXqYhotsSA