Applied to the surface of the floor topcoat is intended not only to impart a better appearance, but also to enhance the strength. But in order to grip when it was at the highest level, it is necessary to use a primer for concrete floor. It should be understood, that its species there are many, and it is necessary to choose the best option.

Need

You can not do without priming the subfloor during repairs. Finishing materials in this case are somewhat longer than usual, and besides completely protected from mold or mildew. Adhesion is also enhanced.

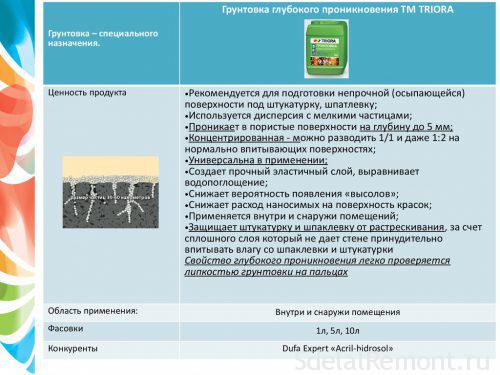

It is worth noting, it is practically impossible to remove all the dust from the concrete floor. This is due to surface feature. That dust will contribute to poor-quality bonding with the base material. To avoid this and used a primer for floor screed. Most often, the store is presented to implement a liquid form of the material. To use it will have to be diluted with water in certain proportions. In addition, there are two main types of primer for concrete floors:

- special applications. It applies only in one direction - either inside or outside the room.

- universal. Can be used, within, and outdoors.

However, they have their own characteristics technical characteristics, and the presence of features and functions. They may have a different level of protection for gender, to resist various influences.

Features of the application

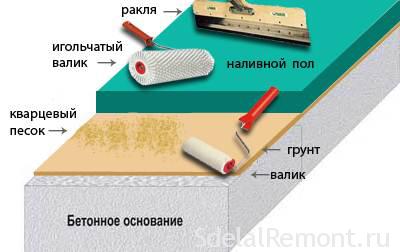

When it comes to cast concrete, then there is no primer can not be dispensed. This is due to very smooth surface, for which it will be very hard to catch subsequent layers. But also the primer must be composed of quartz sand. grip levels will increase significantly due to this. As mentioned earlier, This allows even get rid of the existing dust, which will manifest itself negatively on the quality of adhesion.

When applied to the floor layer polymer coating concrete floor, it covers the existing dust thin layer. Here she was in no way affects the level of adhesion. Vacuum cleaner and broom, together are not able to express in this way their quality.

When you purchase is worth taking for the materials from a single source. This is due to the fact, that there may be instances of incompatibility. Only quality products will contribute to the quality finishing, as well as the safety of all walks.

Consumption primer mix will depend on the material. The median - 100-300 gram. Thus it is necessary to pay attention to surface dryness and humidity levels. Assume only the minimum rate of the last.

Classification

Building technology is not standing still and is constantly can meet all different technology and materials for. The same applies to the types of primers. They are not only meant for the preparation of the basis for subsequent finishing, but also strengthen the surface. For each such material provides its own formula. It is indicated for the appointment of a primer for a particular type of work. It is to provide the following types of, which are mainly found in the construction network:

- regulating the porosity.

- Designed to strengthen the foundation.

- penetrating.

- Raising the level of adhesion.

- Creating a smooth and level surface.

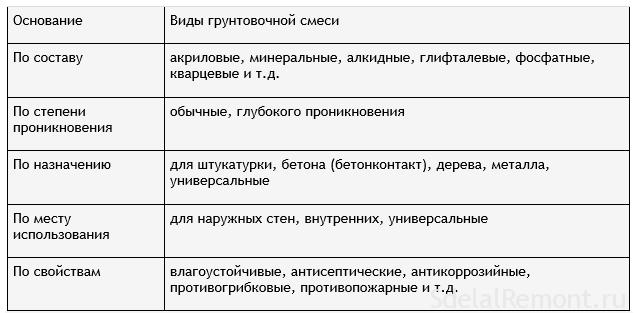

But there is another classification, which is focused on the composition of indicators:

- acrylic. It is also called emulsion. Suitable for preparatory works, regardless of grounds. In addition to the concrete floor, they are applied to the tree, Plate fiberboard or particleboard, brick, cement, etc.. According to the composition in any case can not be processed iron dark. There will be a mandatory event, rust. This should be taken into account, when a concrete floor appear reinforcements. To work sufficiently dilute the composition a certain amount of water. Primer dries within 2-4 hours after application. The estimated cost is 0.6 dollars per liter of formula.

- alkyd. It is used for the subsequent paint application layer.

- polyurethane. Suitable for concrete floors, if in the future it will be applied to the enamel. Its still called epoxy. It is believed primer deep penetration. Also the coating of the concrete floor, the mixture intended for subsequent filling compositions, self-leveling. All the pores in concrete clogged due to tiny particles in the primer. Simply put, they are like a glue between two layers - the concrete floor and finishing.

- Polyvinyl acetate. When using it in the future must be purchased for PVA paint. After applying the surface dries within 10-15 minutes.

Building codes indicate, that the floor-screed waterproofing layer should be applied to the primer without any interruption. Should get a continuous layer.

We should not forget about betonokontakt. It is created from quartz sand and acrylic. Slightly rough surface is obtained, that significantly increases the level of adhesion of subsequent layers. He has a certain set of benefits, which include:

- Speed of drying. For the next phase can begin after repair 2-3 hours after application to the surface of the concrete floor.

- Protection against ingress of moisture. After drying the obtained film at basis, capable of performing addition and waterproofing function.

- Long life. It can be fully used for 80 years old. But much will depend on the brand and quality primer.

Use betonokontakt possible only through 4-5 hours after, How to put cement. This is provided in the building regulations. Only in this case the quality of the material is at a high level.

The choice of material

Prior to the beginning of purchase for priming the concrete floor should pay attention to the floor itself, his condition. If it's humid, it is best to buy acrylic compositions. There also are special components, protects the surface from the appearance of fungus and mold raids. Such compositions applicable to basements, where there is no sunlight.

Deep penetration is required for surfaces with a large number of defects and destruction. If you do not, it is unlikely to get a quality floor screed.

Polystyrene concentrates have a somewhat different purpose - protection against high subfloor humidity, and no current conductance.

This indicates, that the purchase should be dealt with carefully, selecting exactly the material, which is required for a particular room. Otherwise, it will only be a waste of time and money. It is important to be aware of, than to treat the concrete floor.

application Procedure

When the selected treatment for concrete floors, you can proceed to the next stage - priming. There are certain rules, from which it is impossible to retreat under any circumstances. The floor surface is carefully prepared for application. The best option - to use a vacuum cleaner construction, which will deliver the maximum of debris and dust. You can also take in the work of a normal vacuum cleaner with broom. It all depends on the capabilities of.

A special container for the primer is purchased to facilitate the work. its cost is low, but it is convenient for application. Suitable for applying a brush or roller. The amount of work it will have an impact. The process should be to protect yourself, armed with protective equipment for the body, hands, eye. Some compounds are toxic and can corrode the skin. In addition, the formulations usually sticky and very good eats into the skin, which causes severe irritation.

Looking at the instructions from the manufacturer divorce primer floor screed. The proportions must be respected in the exact form. Thereafter, the mixture prepared is applied uniformly over the entire surface in a room. This is the first layer, which must be completely dry. The drying time will depend on the type of material, and everything is written on the packaging by the manufacturer. Next a second layer is applied, and optionally - a third (to better enhance the loose surface). prime concrete floor It will not be difficult, even a novice builder, repairman. The main thing to observe minimum requirements at each stage.

self preparation

Handyman come up with various ways to reduce the financial costs. For this purpose, even coming up with a primer, which you can prepare yourself at home. As the base material serves to work PVA glue. Adhesion of the surface significantly increases.

There is a sequence of a primer for floor screed alone:

- The container is filled with the prepared PVA glue of about 250 ml.

- Thereto was added to half a liter of water. This is due to the optimum proportions of the components 1 to 2.

- After mixing the components of a home primer should get a homogeneous mass in liquid form. The adhesive mass has to be fully diluted with water. To do this, everything is done with vigor and the most rapid pace.

After application to surface It remains white trail.  In this case, there are features in ease of work. In addition to the concrete floor, such prepared mixture is perfect for tiling or laying linoleum.

In this case, there are features in ease of work. In addition to the concrete floor, such prepared mixture is perfect for tiling or laying linoleum.

To improve the quality and strength of self-prepared primer, use an additional component - the crushed chalk. Its quite a small amount of, to get the desired result.

considered options a primer for concrete floors can be purchased in the construction market. But we should pay attention to what, the best option - the purchase of materials for the repair of the premises of the manufacturer. This will eliminate the chance of misalignment between an individual compositions. Application process does not take long, that allows a short time to bring the room in the proper form.