In carrying out major repairs in any premises very often resort to sex selection instead of the old ties. This is due to the fact, it is not always possible to meet the equal basis, on which to lay the flooring even in new buildings or buildings with history. As for the floor screed, i.e. an intermediate layer between the covering plate and the coating, in panel houses, here has its own characteristics, which should be read before the entire process. Otherwise, you may be in trouble, not only with its neighbors, but also management companies.

notion

The House panel floor screed, regardless of, what option is selected, created to strengthen the foundation. With all of this very high quality made gender alignment in the panel house. If done efficiently and in compliance with technology, the flooring flooring is quick and easy. In addition to this increased duration of the maintenance period material, used in the.

Performed ties in panel houses also for the purpose, that was not in vain all repairs in the rest of the apartment. smooth and Rovnosti half striking each, who enters the room. If the home is not possible to carry out the screed floor in the panel house, it is best to contact the experts, who will perform at an acceptable cost of the entire volume of work in a short time.

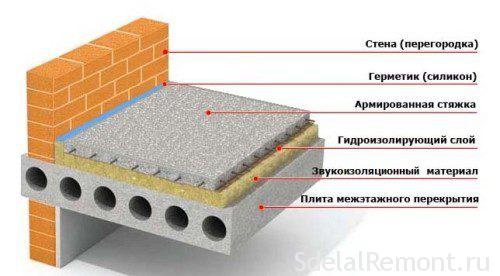

When the tie layer can not forget about soundproofing. After all, for panel houses inherent audibility neighbors not only from the upper floors, but also downstream. So relaxed and comfortable feel in the apartment, that the device floor screed should consider this layer.

types ties

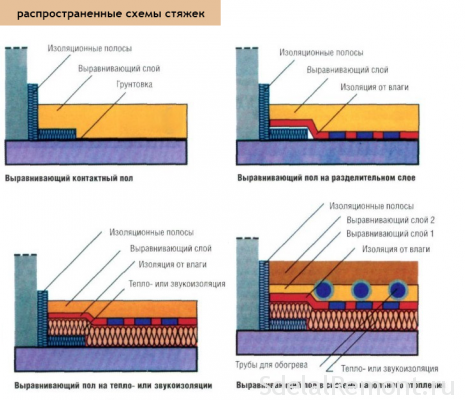

All variants of floor leveling have a different purpose. Some favor the formation of a warm floor system, and some act in the capacity of finishing the base. Everything will depend on the specific situation and the desire to perform a flat floor for all requirements and regulations. Ties are divided into the following types:

- Cement-sand.

- Self-leveling mixture.

- dry screed.

- combined.

The most common option is considered to be Cement-sand screed. He is perfect for leveling the subfloor in the panel house, when the difference between the low and high points does not exceed 40 mm. But even in this case, you should pay attention to the slab, in which they are able to, what kind of load can withstand.  As materials for this type of screed suitable common components, as the sand, cement, etc.. The mixture itself can be prepared with the addition of expanded clay, to facilitate the whole "pie". The load on the slab in the panel house in this case is markedly reduced. Read more about kyeramzitnoi styajkye.

As materials for this type of screed suitable common components, as the sand, cement, etc.. The mixture itself can be prepared with the addition of expanded clay, to facilitate the whole "pie". The load on the slab in the panel house in this case is markedly reduced. Read more about kyeramzitnoi styajkye.

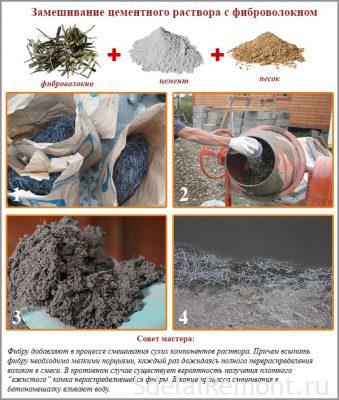

Currently, the technology has allowed to use cement-sand screed various polymeric components. It focuses on the polypropylene fibers. It replaces the reinforcing mesh or other reinforcement options, which also reduces the whole solution, but, Consequently, and the pressure on the overlap. All these points are very important for the House panel, because they do not always design allows you to create a serious burden on the base during operation.

The most frequently used in prefabricated houses self-leveling mixture. They help build a solid floor screed. elevation, which allows you to hide this design, are from 20 to 40 mm. Installation of screed is very simple and easy. It does not require special knowledge and serious requirements in the test plan. It is very important in that case to arrange a waterproofing layer, after which it is carried out screed.

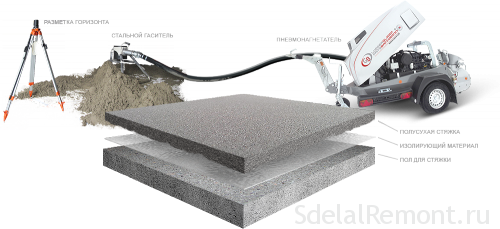

It is worth paying attention to the new popular method semi-dry screeds, that the screed technology in pre-fabricated house is very fast and is, which requires the use of special equipment. Its cost is high, For this reason, it is best to use a contract. Only appliances with the best results will be achieved on the quality and durability of the surface. The term semi-drying screeds, compared with cement-sand screed, reduced approximately 2-3 fold.

preliminaries

Particular attention should be paid to it cement-sand screed, as it is very popular among the living in prefabricated houses. The first step is to hold a series of preparatory activities, which include not only the purification of the base of the debris and dirt, remove dust using a vacuum cleaner construction, but the device waterproofing layer. polyethylene film can be used in its as.  If you have large projections of mortar between the floor slabs, they should be cut off as far as possible, subsequent to reduce the thickness of the entire fill. Subject to shear mounting tabs.

If you have large projections of mortar between the floor slabs, they should be cut off as far as possible, subsequent to reduce the thickness of the entire fill. Subject to shear mounting tabs.

When the preparation is done, quality should be implemented at the base markup, noting the zero level and the level of fill future ties. All the measurements necessary to produce carefully and accurately, because from them will depend on the evenness concrete floor, and the thickness of the solution casting. In this situation, it is worth paying attention to, that not every pre-fabricated house is the ability to create a heavy load on the overlap. Especially when it comes to old buildings. Before starting work, it should be clear to all the base and the opportunity to assess the state of.

Soundproofing

The major problem for panel houses - a large amount of noise from neighbors. When the device floor screed should think about it and make a further soundproofing layer, which allows to reduce the noise level, entering the apartment through different sources.

Before, how to align the panel floors, should think about the quality of sound insulation. different components and materials can be used in its capacity as, which range includes the construction market. This can be a mineral wool slab with a thickness of 50 to 100 mm. They at the same time will have a different density per cubic meter.

Additionally, it may be arranged soundproofing from the existing communications. If arranged floating floors, that are commonly used type "Shumanet-100C". It is performed in two layers on different sides of the tap or other tube. When a device is self-leveling floors in apartment, it must not be forgotten when one of the layers, which is provided by the technology of smooth floor for the prefabricated house. But it is necessary to determine the order, when you can pour self-leveling floor, which in this case shall be observed and be produced Substrate.

We can not forget about a waterproofing layer on top of the insulation. In addition, it is worth noting, except that the heating pipes must be laid on the further insulating material overlap. Here, a great option is a type of "Shumostop-C2".

If you do not deviate from the manufacturer's recommendations and experts, who has extensive experience in this direction, you will eventually get all the quality. Virtually no noise does not come from the lower floors. But even the smallest inaccuracies and errors lead to the manifestation of sounds.

installation beacons

When the cement screed for leveling the subfloor should consider the location lighthouses. Initially, you should choose their particular variant, which will play a completely different function depending on various conditions. Before, how to learn, better to make a screed in the apartment, made the purchase and installation of beacons.

Location beacons should be the, to them easily pass rule for leveling solution. This indicates, that the beacons should be installed at a distance from each other along the rows less, Typically length than approximately 15-20 cm. Besides landmarks They must be located at a distance 30 cm from the walls in the room and strictly on the level. It is made from high quality of this step will depend on the casting floor sand cement mixture. All will come from the lighthouse. If you will be respected technology, the screed floor in a panel building high quality will. In any case, you should pay attention to the thickness, which should not exceed the admissible limits. Under certain circumstances, in general, you can use ceramic or analogues thereof to reduce the total weight of the future ties.

The process of filling

How satisfied screed in the apartment, It depends on the financial situation. There are plenty of materials.  It is possible to grout the floor parts to cook yourself or buy ready mix with all the necessary components, in which it will be enough to add a certain amount of water.

It is possible to grout the floor parts to cook yourself or buy ready mix with all the necessary components, in which it will be enough to add a certain amount of water.

But many question arises, whether it is possible to pour the floor parts. This can be done, but it is best to make the distribution of the solution in the whole house in one go. At the beginning of the work is not superfluous to moisten the surface of the pre-solution, contacting the subsequent casting process or means for increasing the level of adhesion. In such a case would be a good grasp, and consequently, and solid to obtain the necessary.

Scheme pouring floors will depend upon the particular, as well as the existing experience. In any case and at any time you can invite experts, until everything is spoiled. They will be able to bring everything to its logical conclusion.

What to do after the floor screed in the apartment? There remains only to wait for the complete drying of the solution. But care should be taken in the process of Care screed, so it dries evenly with no errors. For this, the surface is covered with polyethylene film, pre-wetted for several days. It is important to create the same conditions of temperature and humidity until completely dry.  There should be no drafts or low temperatures. Even higher temperatures may only lead to premature drying screed and complete settable mortar mass.

There should be no drafts or low temperatures. Even higher temperatures may only lead to premature drying screed and complete settable mortar mass.

All this suggests that, that is not enough to fill the screed. Very important to keep track of its maturation. After a few days the surface can be walked on, but do not create stress and to mechanical impact. All subsequent work, including decking flooring in the building panel can be made only after the complete drying of the solution. For cement screed this period is typically up to 1 of the month. It depends on the components used and the mixture.

Laying dry screed

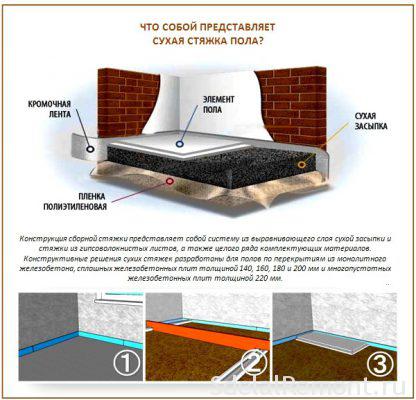

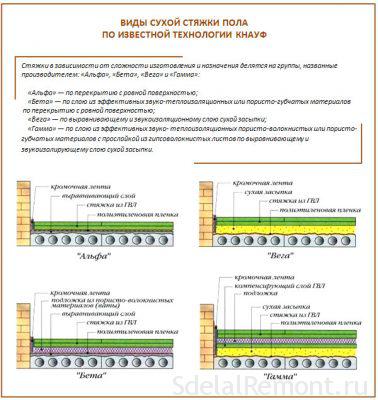

You can not ignore the dry screed, which is often carried out by Knauf technology. There are no difficulties in the mounting process, the main sequence of actions. After the preparatory activities and the creation of a waterproofing layer on the surface, You can perform the filling of the bulk material. They may be entirely any component, It is used for these purposes. The most commonly used concrete block.

After filling should perform special flooring tiles, which may also differ from each other by components. Plates are often based on plaster, with the necessary functions and features.

To connect the plates together and fixing them to the base, apply special construction glue. Screws may remain on the surface of non-compliance with technology, that will be immediately noticeable when finishing. Clay did not create such negative qualities. The surface becomes perfectly smooth.

The process device of floors in prefabricated houses reduces the time of work to the flooring planks or other finishing. Leveling the floor is very fast and does not create any problems for beginners to experts.

Tips from the experts

There should be no problems with the, whether poured floors in the panel house. This is done simply need if you want to create a flat surface and subsequently perform quality flooring flooring. But it should comply with the requirements, major of which is created by the thickness of the screed and roof load.

It is very important to the commencement of work to prepare qualitative basis. From this the final outcome will depend. If you depart from the technology of creating a flat surface regardless of the option selected ties, the consequences do not take long to wait.  Again have to dismantle and disassemble Floor screed.

Again have to dismantle and disassemble Floor screed.

Primer base to the screed will increase the degree of coupling of a solution. The number of layers will depend on the flatness of the floor in the room. Subsequent layers can be applied only in the case, when dried the previous. before applying primer should get rid of the existing cracks, potholes and other damage to the base.

Ties level will determine gidrouroven. From "zero level" and there is the rest of measuring and markup calculations in the room. The process is responsible, like any other technology used in.

In the event of even a small doubt about the quality of the work on its own, it is best to seek help from the construction crews. For a certain amount, depending on the volume and type of work, they will create a truly flat floor in the panel house.