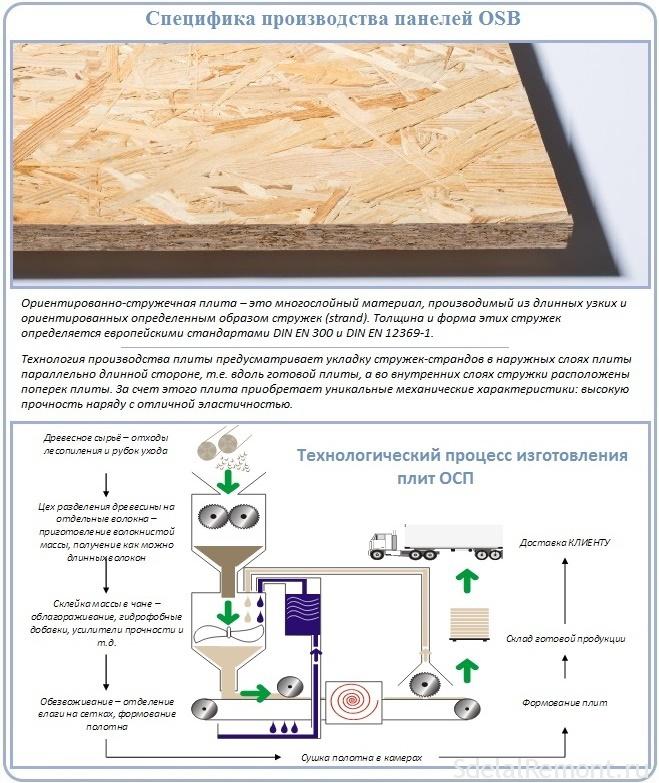

In the market continue to emerge of new materials, with which to align the concrete base. These include, and oriented strand board (OSB). He became a full-fledged replacement for plywood or chipboard. OSB boards also have excellent insulating qualities, that brings them to a leading position. In this case, you need to know about, how to carry out the alignment of the floor and with the help of which there are subtleties in the work.

types of plates

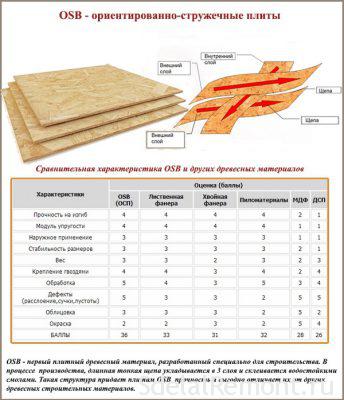

OSB boards are presented in the form of layers of glued wood chips, which is also still very much pressed. Usually, all performed in three layers. Located inside the chips perpendicularly, and in the outer layers - along the plate. The following basic types of OSB:

- OSB-2. Characterized by a reduced level of water resistance, which indicates their use solely within buildings in areas with low levels of humidity.

- OSB-3. It can be called a universal material. It looks great and performs its functions, indoors, and outside, despite the humidity level. Durability and other characteristics allow to apply it in any direction construction. They can withstand external loads on the arrangement of furniture, constant flow of people, etc..

- OSB-4. Also excellent moisture resistance plate and different high strength. With their help, the supporting structures are arranged, including on the premises, where the ever-present moisture.

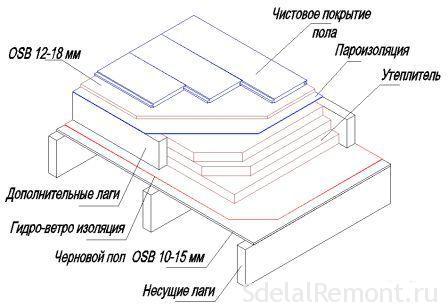

As for the thickness of the plate, much depends on the use. If you want to get rid of the minor defects of the floor surface, it will be enough and 10 mm, but significant potholes - 10-15 mm. Even greater thickness required for the floor joists on the device. In this case already must choose layer 20-25 mm.

Application area

When used on the floor laying OSB, it should be understood, for what purpose all this is done. There are the main directions, where the active material is applied:

- Use as a final floor finish. In addition, you can draft floor on joists.

- alignment surface. After placement of such a material on the basis of concrete or wood, you can easily begin to hold the flooring floor covering of any kind.

- soundproofing. OSB can absorb almost any kind of noise.

- thermal insulation. The basis of the material - 90% wood chips, that is, a natural component. This shows the high thermal insulation properties. The heat does not go out of the room, and besides the great kept at the required level.

floor device OSB-plate

It is worth paying attention to, that there is sufficient technology, through which you can fully perform the laying on various grounds.

Benefits

Any room can be brought to the ideal state, if used in the OSB. In some cases, do not even have to make a subsequent finishing subfloor. Allocate and other strong arguments in favor of selecting the material:

- Convenience. one such plate size, that is able to cover a large area in the room. Logs may thus be spaced apart at a distance of 56 cm. This in turn makes it possible to place between I propose selected option insulant.

- Simplicity. The work can be done in-house, even without the use of expensive equipment and tools. It requires only a minimum of knowledge in the construction industry.

- Favorable price. If you compare with other similar materials, the OSB on the concrete floor will cost slightly less.

- Reliability. After fixation fasteners, cooker remains at this place firmly and securely. Besides fixing sticks into fine design not loosened during operation. Even with the shape and thickness over time remains the same, to withstand heavy loads.

Right choice

Because of the huge range of very complicated products on the market to select a specific option for. To blow the axis on the floor of high quality turned, should follow certain tips, With regards to the choice of.

- Preference should be given to European and Canadian producers. They are leaders in quality on the market.

Here fully respected technology, adhering to all requirements.

Here fully respected technology, adhering to all requirements. - In stores you can find most of OSB-3 plate, which is perfect for the device and leveling floors. As a result, a reliable and robust design with a high degree of protection against moisture.

- Depending on the destination (concrete floor, wooden, lag) is selected and the appropriate material thickness for.

- Standards in size OSB - 2.44*1.22 m. for repair based on the number of products will be calculated, paying attention to the area of the whole premises, their order relative to one another. cutting of slabs can be carried out by means of circular saws. Even in this case, how quickly you can level the floor.

In the best waive the jigsaw for cutting the reason, that the lateral surface is rarely remains flat.

Installation on a concrete base

If necessary to carry out the floor leveling OSB, should be carefully prepare base for. To close up all the possible cracks and potholes, get rid of the maximum defect. No debris should be. After the mounting adhesive must have excellent adhesion to the substrate. No harm will cover the concrete floor primer to create a dense film on the surface. During operation, it saves the screed by dusting.

The following action - Unfolding sheet across the surface in the room. boards should trim along the walls and other structures on the size. Wrong side plates covered with parquet adhesive, having a rubber-based. Glue is applied to evenly across the width of the material, using a notched trowel. Thereafter, the bonding of the sheets on the concrete floor.

For reliability, the whole construction is fixed precast slab OSB dowels. So that there were all strong, fasteners located at a distance 20-30 cm apart. The exception here is flat floor and dry room, when it will be enough dowels only at the corners of each of the plates.

Between the plates must remain dilatation joint, width of about 3 mm. Between the wall is maintained also seam, but several more - 12 mm. These gaps will facilitate expansion compensation plates under the action of temperature and humidity changes. No blistering throughout design during use will not occur.

The final stage - the cleaned surface from dust and debris. Having seams along the walls in the room are sealed with foam. The whole "pie" will be dry for about 3-4 hours. More accurate data are displayed on the instructions from the manufacturer. In the presence of excess foam, it should be cut with a sharp knife. Further it is possible to perform finishing work on the flooring and decking.

I propose a mounting

You do not need to use a leveling screed to create a flat surface in the room, if you buy OSB. It saves time due to the fact, that does not prepare the solution for leveling the floor with their hands. This to some degree reduces the total cost of repair.

At the same time will have to perform installation lag. The design created by the same material can be placed to improve protective functions against moisture, too much sound and noise, as well as improve the quality of thermal insulation. Also here there is a floor leveling quickly and in no time.

Fixing lag to the concrete base is performed using anchors or dowels. Depending on the thickness of OSB boards acquired distance will be defined between the lags. The thicker, the wider the distance. When you step in 40 cm, It must be available a plate with a thickness of about 15-18 mm. If the distance between the beams is greater than 60 cm, and the material itself should have a thickness of at least 22 mm. This includes floor leveling technology OSB.

After such a construction, the device will turn inside space, which can be filled with different materials. This is mainly insulation. For the first cold floors is perfect heat insulator in the form of mineral wool or foam, and in the presence of wet basement - isolating film or membrane.

Location boards should be carried out across the lag. We can not forget about the expansion joints, which should be determined in the middle of the lag. Gap is not just between the different plates, but also along the wall in the room. Used sheets may be attached to the joists with nails or screws. True Nails is best to choose spiral or ring. Along the perimeter of the sheets must be held in the mounting step 15 mm, and at intermediate supports - 30 mm. When using nails, be extinct distance from the edge of the plate approximately 10 mm. As for the size of the fasteners, the length should be approximately 2.5 times more, than the thickness of the sheet used OSB. In this case, the alignment of the concrete floor with their hands will at the highest level.

OSB processing for finishing

When the response is received, how to align the floor OSB, you might think about finishing. Processing should take place in strict compliance with technology. The easiest option - to cover existing varnish sheets, put around the perimeter of the walls along the baseboards and enjoy the natural material type. Yet in most cases,, when they think about, how to align the concrete floor with their hands, subsequently operate decking flooring. Feature processing depends on the type of coating, as well as the desired result.

- Ceramic tiles on the floor. base construction must not move, move. This is largely touches the floor on joists. The surface to be sanded with a wire brush or sandpaper. The work is only applied special glue, the ability to connect the tree and ceramics. Only in this case will turn out perfect alignment with the subsequent trim tiles.

- Fine finishing. As I mentioned earlier, the surface is not covered by anything. But it should be careful to think about protecting plates from external influence. For this purpose, on top of the varnish is applied in several layers or other special means. They will create a barrier against the deterioration and destruction. Special components within the covering elements prevents the appearance of insects, and in particular bark beetles.

- Strong and rigid materials is laminate. It can also be used for leveling the coating layer of the OSB. In addition, the laminate has a special attachment, which allow to forget about the many other requirements, placed on the ground floor. As a result, should get a smooth surface. The interior is not only beautiful, but also durable.

- Linoleum. There is an alternative this floor covering - carpet. For their deck have a very important requirement - the base floor must be perfectly flat. Otherwise, you may encounter a serious defect over time. In addition to the performance of elevation changes negate the appearance and attractiveness. Stepping on a surface, you can feel every defect (cracks, slit, intervals, convexity, screws, etc.). One level will provide tsiklevaniya process, and this will have to do before installing the floor.

Use for OSB alignment subfloor in any room provides a flat surface, which subsequently can be placed virtually any embodiment of floor covering. Observance of technology will lead to a positive result. The main thing correctly to choose a particular type of plate to work and follow the instructions.