Heat in the apartment can go for nothing. And the main reason here is, that there is no insulation in the bottom of the floor or of poor quality it is laid. After half can go order 20% all the heat. Here it is necessary not only to change the flooring, but also to choose a high quality material for packing. In some cases, the best option - a complete replacement of the floor screed. It all depends on the specific circumstances. It is important to know, how to insulate the concrete floor in the apartment.

The choice of material

In the construction market there is a huge amount of material, which can be used as insulation. At first glance it is very difficult to make a specific choice in favor of one of them. Insulation must be selected not only on the cost of the, but also in quality. Each of them is able to perform a variety of functions and tasks in service, you should pay special attention to. There are some basic criteria, which draws attention when visiting the store:

- ecological purity. Device floors and floor insulation should not have a negative impact on the environment and on man in particular,.

- With a high degree of water vapor permeability and resistance to fire or elevated temperatures.

- Confrontation sun exposure, increased levels of humidity and temperature changes in the room.

- Easy to install insulation on the floor, as well as handy use.

For this reason it is worth considering that, what material is best to choose, to properly arrange warm concrete floors their own hands. they will be different for a particular room. This may be a bath, balcony, apartment, homes and other. Attention is drawn to the possible burden on the subfloor during operation, and the properties of the environment. Insulating materials thus show their quality in different ways. Among the most popular, you can choose:

- Mineral wool, and fiber, fiberglass.

- light mix, based cement and additives. Here mainly choose keramzit.

- Corkwood, chipboard, dry chips, ecowool, plywood sheets.

- Thermal insulation of concrete floor Penoplex.

- Insulation in liquid form - the paint, which is capable of creating a porous layer on a surface of the thick 5-7 mm.

- Materials with foil side, Styrofoam, polymer materials.

For wet areas not intended wool, as it is very well it can absorb. For this reason, it is best to pay attention to other materials.

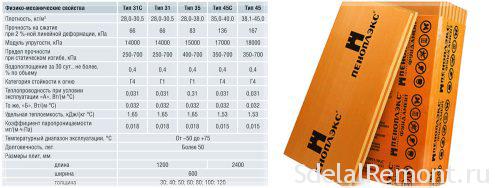

properties Penoplex

When it carried on the floor laying polystyrene, you can be sure, the moisture in it is absorbed only minimally. In addition, for the duration of the operation and the constant presence of water on the surface, they only partially be absorbed Penoplex, whereupon absorption will not be made. Moisture enters only into the outer material of the cell, which can be damaged during cutting or mechanical action. For this reason, care must be taken when installing insulation on the floor.

With very few Penoplex chemicals can react to a floor construction or device in the room. But as always there are exceptions in this case,. In implementing the floor leveling Penoplex, you should not worry about such negative manifestations, as decay and decomposition. The material remains intact. But we should pay particular attention to the ambient temperature in the room when installing on Penoplex floor, as well as during operation. In this case the state and integrity of the slabs will be unchanged.

methods

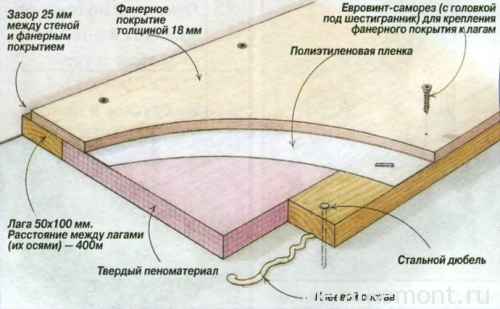

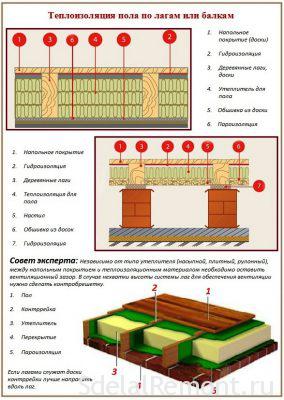

When insulation can use various options for placing the material. Among them are laying insulation on a concrete base I propose a. After this is done only boards on the joists and flooring fixing. The resulting voids insulation lays, as well as all possible communication in the apartment. Loads in such a case, the material will not be. Consequently, You can acquire and use the bulk materials in the form of expanded clay or mineral wool.

But initially performed deck waterproofing layer. Insulation must be fully protected from moisture coming. Stacked on top of the lag nailed plywood sheets leaving a gap in the 16-20 mm from the walls. At the end will only perform the selected flooring flooring. On this floor finish and the room will be completed, which will be warm, and will not miss the warmth of the room.

When placing a heater directly onto the concrete surface, material is selected so, so that it can withstand the stresses and external influences. These can be mineral or styrofoam slab. Styrofoam on the concrete floor also performs the role of the screen when the device warm floor. Screen reflector will reduce teplopoter, the effect of the space heating will be the best. The device polystyrene flooring will be the most optimal and demand due exhibited positive qualities.

We can not forget about the technology of the 'floating' floor. In this case, mounted under the foam board concrete floor. floor laying is carried out in layers. Initially plank material for insulation. If you are using floor heating system, that makes installation of the heating elements, and only in the end of - concrete screed. But you should pay attention, that filling is performed across the substrate. No connection with the base and the walls is not satisfied. floor screed cake should get a "floating" state.

On concrete base

To determine the thickness of insulation layer, it is best to pay attention to the manufacturers' recommendations. A layer of insulation usually 50-100 mm. The increase of oriented to the cold climate regions.

Laying insulated floor materialize only if the technology and the implementation of all measures consistent:

- Substrate preparation. Existing cracks must be sealed. Grease stains are also deleted, paint stains and other negative aspects, which may affect the quality of the insulation.

Any debris and dirt, even dust, should not remain.

Any debris and dirt, even dust, should not remain. - Sealing layer. In addition to the standard polyethylene film is best to use more modern materials. This can be IZOSPAN. We can not forget about the overlap on the wall of the insulator around 10-15 cm. all joints and overlaps materials should be glued to the tape-based metallized.

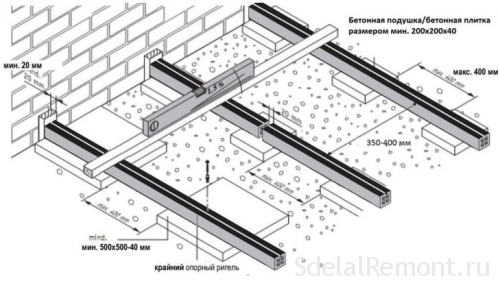

- installation log. Their height will depend on the insulation layer. As for the location of the pitch lag, it must also focus on the parameters of materials. lag screws fixation is usually performed, dowels.

- Insulation between joists is located, and then re-covered with waterproofing membrane, which must have a sufficient level of vapor permeability. The rough side should be placed in a heater, and the smooth - from him.

- Fixing of plywood sheets perpendicular to the joists. Instead, you can use plywood decking.

Rules laying lag

Upon the completion of these steps, you are ready to finishing. If you observe the full technology, there will be no question, how to make the concrete floor warm.

Insulation of a country house

There are some features of the application of insulation on the subfloor in a holiday house. The most commonly used in the foam on a concrete base. This is due to the manifestation of different parameters, which is an excellent thermal conductivity, insulation layer (least 10 cm), moisture confrontation, the ability to withstand external mechanical impacts. The foam in this case is better to choose MDF option. Laying floor insulation is performed as follows:

- Prepare the ground for, dried, verified moisture level.

- layer arranged waterproofing, presented by the usual plastic wrap.

- Direct mounting of foam on the basis of the concrete floor.

- Another waterproofing layer.

- Fill insulated floor. The solution should be poured to the thickness, least 50 mm.

only can be carried out after decking flooring, the solution is completely dry and grab.

High-quality insulation on the concrete base almost never choose at a low cost. After all, he is laid for many years, and he should not have a negative influence in the operation of the health. It is better to be done once and for a long time, than constantly remodel.

The use of different materials

Several different technology floor insulation in the apartment, if you choose other material for. So, eg, foams have similar base sequence of preparation. But here then everything a little differently.

insulator plates arranged directly on the basis of concrete floor.  In addition, the material should be placed on the special grooves, contributing to the implementation of the work without gaps. Each sheet is then joined with no spaces. The wall keeps the damper tape. It will contribute to compensating the screed strain. Fixing may be carried out with available adhesive tape or dowel-nails.

In addition, the material should be placed on the special grooves, contributing to the implementation of the work without gaps. Each sheet is then joined with no spaces. The wall keeps the damper tape. It will contribute to compensating the screed strain. Fixing may be carried out with available adhesive tape or dowel-nails.

Thereafter, insulation layer is covered with a film of polyethylene, to screed does not sink into between the plates. This will prevent the occurrence of cracks and voids in the subfloor. Do not be amiss to make a grout reinforcing layer. The frame is taken from steel or PVC. When shading is made, should be given time to complete its drying. It is very important to monitor the status and make caring for tie.

The system considered fit perfectly into the case, if arranged water warm floor. heating circuit when it has to stay on top of the grid for hardening base.

Evaporation materials

Certain skills must be available when using the spray materials for thermal insulation of the floor in the apartment. In addition to this need and special equipment, which can be rented.  The sequence of work will have its own characteristics, which is worth reading pre.

The sequence of work will have its own characteristics, which is worth reading pre.

Initial activities almost unchanged. You do not even need to remove the existing bulges and cavities, even significant. But it is necessary to install the joists for the subsequent finishing. concrete foundation slightly wetted, to increase the level of foam in the subsequent adhesion. On the floor surface is sprayed polyurethane. the main thing, everything to be uniform. Filled all the space, which is available between joists. Thus it is necessary to pay attention to, that in the process of hardening material, foam will begin to increase in size. Generally, all dry for days afterwards. It is best to pay attention to the manufacturer's recommendation, to get the best results.

After drying, the foam can be laid plasterboard or plywood sheets. Will remain in the end only perform finishing, taking certain floor.

The material used is not very polyurethane foam combined with sunbeams. For this reason, immediately after drying should finish cover material. The same applies to the process of drying, when should cover the foam and protected from the sun's rays hit.

All used and popular methods have their own characteristics, you should pay special attention to. In addition, here we must choose the best option for insulation of concrete floor, so that he could show all their properties and qualities. With a clear interaction of all the components of the heat loss in the room will be kept to a minimum threshold. The process of warming the floor does not take much time, but recommends that the study of technology.