During the construction of any building focused on the floor and everything associated with it. Currently, quite modern technology, which allow not only to create a flat surface of the base, but also to make it warm, comfortable, comfortable. Popularity has radiant floor heating, which can be done in-house. And all this despite the fact, At first glance everything is very time-consuming and problematic.

notion

Particularly popular Radiant Floor is for private buildings. This is the great option of heated space. Such embodiment of mounting of floor heating water for apartments is more problematic, than electric.

Water heating system efficiency highlights, cheapness, as the entire work process, and operation. But here is the installation of underfloor heating with your hands a bit more complicated other species.

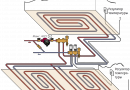

Radiant Floor Heating represented as pipes, which are usually placed on a predetermined scheme. Floor heating was carried out by hot water, that circulate on the laid pipeline.

As for the material for the work, the best option for the price and quality - repoussage or polypropylene. But the final material will be completely dependent on the preferences of the financial component and issue.

In addition to the pipes in water underfloor heating includes other components:

- thermal insulation.

- Collectors with fittings.

- room thermostat, allows you to set the required level of temperature indoors.

- Fasteners etc.

It is important in this case, to choose the right materials for the installation carried out. If their quality is excellent, and the life floors be decades. Sometimes even the whole product kits can be found for sale, which includes all, that it is necessary to complete the installation of the system.

Positive qualities and weaknesses

If you still decide to mount warm floor their own hands, it should focus on its basic virtues, that draws on his side a large number of performers:

- The minimum cost of the process all the work from start to finish. We only need to purchase the entire list of required materials.

- Electric power will not have any effect on the supply of heat by pipes.

Consequently, network outages are not forced to sit in the cold. But the heating in this case should be a stand-alone.

Consequently, network outages are not forced to sit in the cold. But the heating in this case should be a stand-alone. - All the elements of the water floor heating systems with excellent coverage are combined with other elements, regardless of, selected laminate or ceramic tile for finishing.

- It completely replaces classical heating, but, Consequently, hides the communication and does not spoil the look of the entire room. The living room area of the apartment itself can be used to your own preferences to the full.

- connection It may be a heating boiler, to central heating and work independently without fail.

- There is a significant saving of heat. If the room is in the standard version, it will be up to frugality 30%, with significant height ceilings over 3 meters - at least half.

But you can not just dive into the system, since in any case, you can face some negative manifestations of water works underfloor heating. Indeed, in most of the apartments it is run does not work. Only private homes are suitable for heating the interior of the. If the system operates in standalone mode, it is possible to adjust the heating water level, is piped. For the central heating system is already carried out will not work.

If time does not detect water leak from the pipeline, laid in the floor screed, there will be a great chance to flood the neighbors from the lower floors. Much will depend on, observed whether the water floor heating installation technology, and whether all the measures taken for sequential execution of works without deviation.

Materials and equipment

all the necessary equipment required to buy pre-water type underfloor heating, as well as materials for high-quality mounting. If the pipe is chosen, then its optimum diameter should be 20 mm.  As for the material, it is best to take proven - crosslinked polyethylene or metallized. Will generally excellent, if it has anti-oxygen coating. This material is chosen for the reason, that have a smooth shape, do not allow corrosion to appear on the surface, within, and outside, and he system installation process is very simple and takes a short time. In certain areas of the floor of the pipe will be installed more tightly, that should be taken into account when calculating the total number of.

As for the material, it is best to take proven - crosslinked polyethylene or metallized. Will generally excellent, if it has anti-oxygen coating. This material is chosen for the reason, that have a smooth shape, do not allow corrosion to appear on the surface, within, and outside, and he system installation process is very simple and takes a short time. In certain areas of the floor of the pipe will be installed more tightly, that should be taken into account when calculating the total number of.

Radiant flooring require application and other materials, which are:

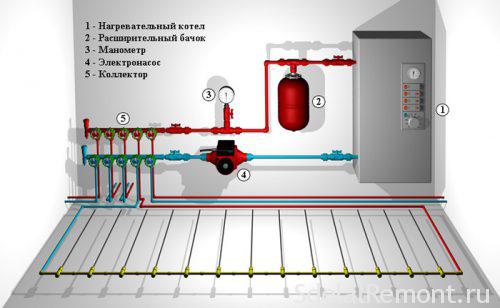

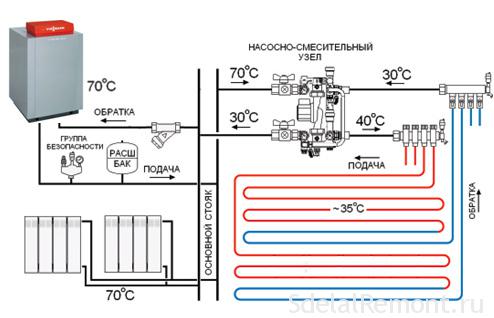

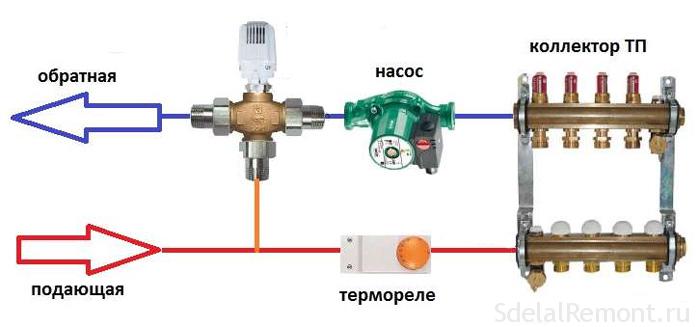

- Collector. It can even be called a key element. They may be packaged with cupboards, which is sufficient to establish the desired location. The desired pattern is acquired from the number of input and output pipes for floor heating system in a given room. Collectors temperature level are provided regulators, pumps, stabilizers maximum pressure.

They can easily carry out the connection is not a heating system, even if they require different supply temperature.

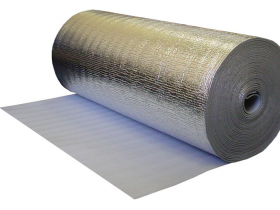

They can easily carry out the connection is not a heating system, even if they require different supply temperature. - heat-insulating material. This can be a foam of appropriate thickness, special film, plate. But about this layer in the system water floor heating forget in no case be, to keep heat inside the building, rather than spending on downstream floors.

- Fitting, for reinforcement of metal mesh, various fasteners, Damper tape around the perimeter of the room, as well as the keys.

When the entire set will be on hand, you can safely begin to work and produce packing water underfloor heating under the screed or other options, and most importantly - on its own.

options device

When designing the heating system project, should consider and choose a rational layout pipe. All can work in standalone mode, or together with a radiator heating. For each variant and provided its technology, which are being installed.

It is worth noting, that savings is a priority in underfloor heating system. Consequently, once is better to spend the money and make laying of pipes under the floor at one time in all areas of the house, you perform the same actions with the high cost of labor and resources in the future.

Training

Prior to installation should be carefully prepared base. no debris, dirt should not be, and it itself to fit the horizontal level.  This is necessary in order, to subsequently perform the same level fill the entire area of the room. In this case, the floor heating will be uniform.

This is necessary in order, to subsequently perform the same level fill the entire area of the room. In this case, the floor heating will be uniform.

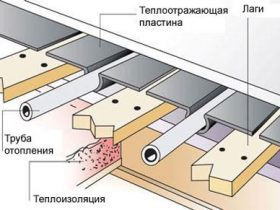

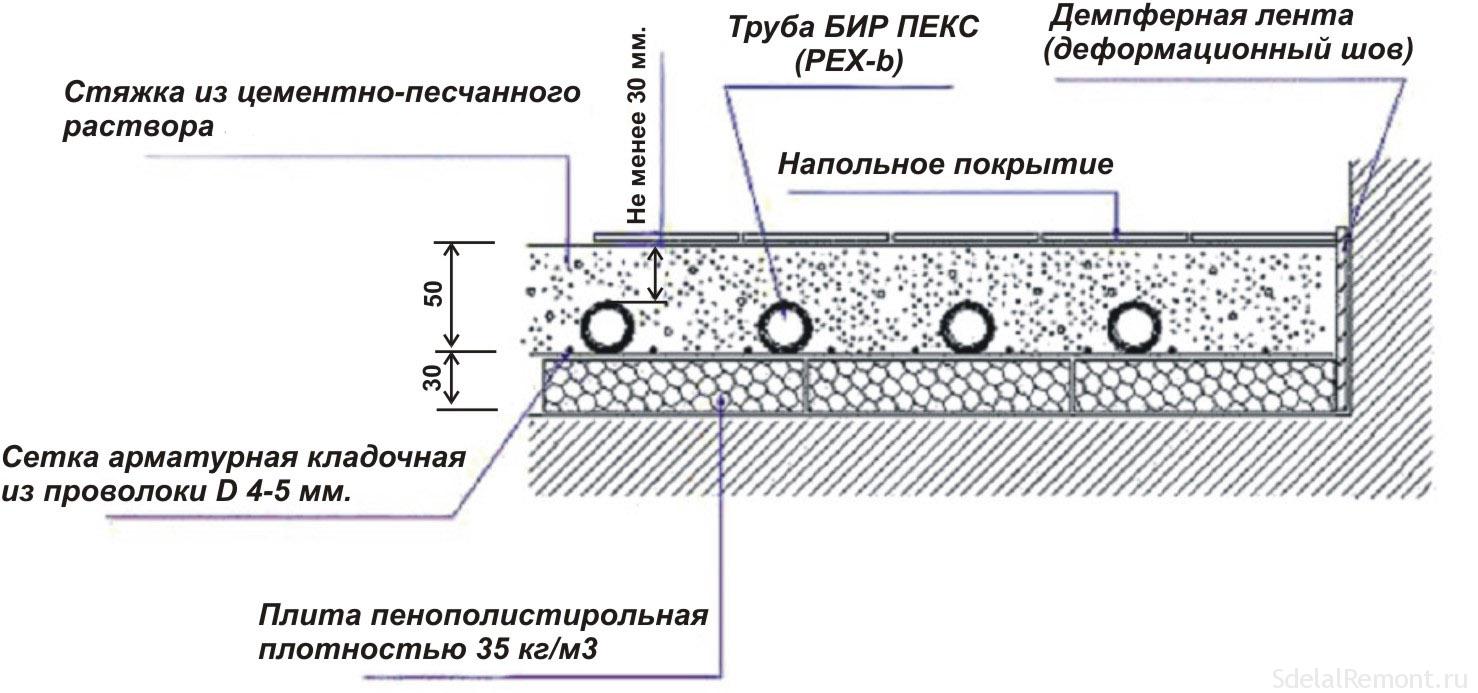

Thereafter, a heat insulation layer by means of a pre-selected material. The film is laid on the subfloor to protect against moisture possibly entering with lower levels. Moreover, the layer will not allow the heat from the waste pipe, and saves it to return to the room.

On the wall mounted damper tape, which serves to compensate for the expansion of ties with heating. Bonding tape is very simple, because it looks like a normal tape. Width is taken about 10-15 cm. everything will depend on the height of the final casting.

With specific regard to thermal insulation material, its thickness will affect the location of the floor, where mounted floor heating water with his own hands. Particular attention is paid to the first floor, directly above the cold cellar. Here insulation height can reach up to 25 cm. Each material has an almost identical heat conduction component. Of particular interest is the glass wool, EPS, foam concrete, minvata and t.d. Any device materials particularly under water underfloor. They are represented in the assortment in hardware store. We are talking about a plate with projections, serving for laying heating pipes in their. Moreover, the installation of the entire floor heating system in such a case can be made much easier and faster.

The nuances of installation

When the installation begins water floor heating system, should come to the process with the responsibility. From the quality of the work the duration of the maintenance period will depend, as well as the durability of the entire floor structure. mount technology water floor heating comprises a sequence of several very important milestones, without which do not succeed:

- It all starts with the collector. In this case, the wall, of the installation should be strictly vertical. But the distributor is mounted on the basis of the horizontal level. The paper can be useful not only to the normal level, but also laser level, allowing to obtain a more accurate measurement results. Also popular and water level. If there are obvious deviations of the axes, then subsequently be possible to incorrect operation of the heating system.

- About preparations mentioned earlier, with them also necessary to be careful, so as not to miss a single item.

- According to a predetermined scheme carried pipeline installation. the main thing, that did not happen bends them in any direction during installation. This will only result in damage to the hull and subsequent water leakage. After that, all pipes are attached to the manifold by means of fittings.

- When the collector is connected to the tubes and the whole floor heating system water, you can start testing. Within approximately 4-5 minutes supply pressure, as well as the water temperature in the system was gradually increased. If in this case they will not be detected leaks, You can enable the maximum feed mode (test pressure). In the absence of specific knowledge of the plumbing and electrical industry, all kinds of works on connecting the collector is best left to a specialist.

- Testing is successful - you can start screed. Initially pipeline is laid on top of reinforcing mesh, after which the solution is distributed uniformly throughout the water floor heating system surfaces. It is worth remembering, that in the solution should be appropriate additives, which are intended directly for underfloor heating. If there is no time or desire to cook their own fill, you can buy ready-mix, which range includes the construction market. Filling is done on the room side to the central part. Skilled artisans may produce the distribution of the solution at working floor heating system at a temperature of about 20-23 degrees. But still it recommended at all to leave him alone until dry option selected ties.

- When the screed has dried, which usually occurs within a month, you might think about finishing and manufacturing of flooring flooring. In this humidity floor surface should not exceed 4%. The components used must be designed directly for underfloor heating. To a large extent it concerns a heat-resistant tile adhesive. The adhesive layer will depend on the thickness and the time for complete floor warming.

This all allows us to answer the, How to make a warm floor with your hands. The process at first glance, a very time-consuming. But if you perform in stages, step by step, that no difficulties would arise precisely. The most important thing to choose the high-quality material to work from leading manufacturers. But for each option should be chosen for something special. No harm will consult a specialist. That will have a heating system, that does not spoil the interior, and the aesthetic appearance of the room.