Traditionally formed, Heated floor that is arranged in the concrete floor of a certain thickness. But technology does not stand still. For this reason, the optimum was found embodiment mounting water underfloor, which is called dry screed. But not its direct entry is meant by this concept, and a team of screed without "wet" support. It should deal with the, how to perform and what kinds of jobs will have to perform.

application

When a water floor, dry screed can be applied depending upon certain conditions. They have several options, differ in the materials used.

dry screed warm water under the floor can be arranged at:

- low ceiling. Concrete screed in this case would create a serious burden, for example a wooden support or old plate.

Dry method is to avoid difficulties in the work. It is about 10 times easier concrete pouring (about 20-30 kilograms per square meter).

Dry method is to avoid difficulties in the work. It is about 10 times easier concrete pouring (about 20-30 kilograms per square meter). - At low ceilings. Creating the concrete screed - increase floor level with respect to the entire surface. In such cases, it is best to do without pouring the prepared solution, except in cases, when all the subtleties of design solution provided.

- There is no possibility to make concrete floor over underfloor heating. This may be a step in the house vysokoraspolozhenny. Here it is problematic to carry out the delivery of concrete to the installation site. In addition, all require a large amount of money. Not always on-site is very easy to prepare a solution for performance pouring concrete screed. In this case optimally arrange a "dry" tie.

No wet work is not for the chosen technology. It eliminates the possibility of water leakage on the downstream floors.

pros

If you are warm floor dry screed, you might encounter with a sufficient amount of its positive qualities.  Among the most frequently occurring:

Among the most frequently occurring:

- The design gives a very easy, when the overlap is not generated almost no load. Subsequently styling can produce any type of floor covering.

- The overlap can be not only concrete, but also of wood. That is, there are no restrictions there is no.

- Once executed system installation water floor, You can proceed to the deck floor covering selected option. This significantly reduces the time frame of the work, which is especially important when the need for rapid settling in the living room.

- Screed obtained insignificant thickness, that almost does not affect the height from floor to ceiling in the room.

The most important thing in this situation - qualitatively all works, to get really efficient room heating structure of the subfloor.

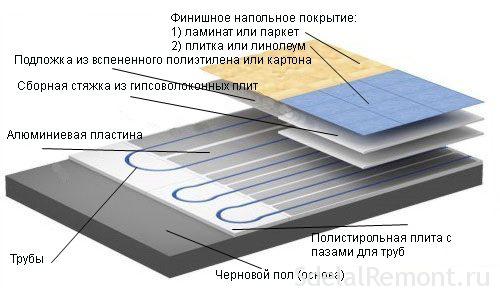

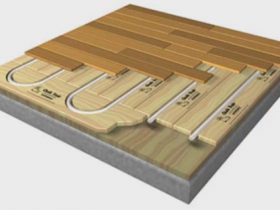

Necessary materials

When not in use concrete fill over underfloor heating, It provides polystyrene or wooden base.  It already has grooves, where the tube is placed floor heating. In addition, it uses a metal plate for a competent distribution of heat. When produced on the selected circuit assembly scheme, You can almost immediately start to the deck floor covering. But until this stage should be laid on the surface of a substrate tube for protection against moisture. As the flooring is most often used laminate, tiles, carpet or flooring.

It already has grooves, where the tube is placed floor heating. In addition, it uses a metal plate for a competent distribution of heat. When produced on the selected circuit assembly scheme, You can almost immediately start to the deck floor covering. But until this stage should be laid on the surface of a substrate tube for protection against moisture. As the flooring is most often used laminate, tiles, carpet or flooring.

Particular attention is paid to pipes for floor heating, since they will depend on the heat transmission quality and duration of the maintenance period. The most expensive, but having excellent characteristics and properties - copper or stainless steel tubes. Greater demand in the market are plastic materials, evolved simple installation, low cost and the ability to withstand aggressive media. Working life, they are not much different from the same copper analogues. In addition to water in such systems it is possible to actively apply various types of antifreezes. Any negative impact they have will not be able.

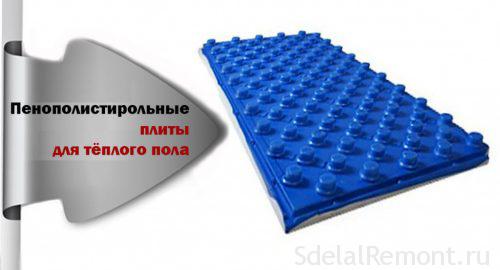

Underfloor heating screed without the required quality insulation. It is used as a special plate, produced from expanded polystyrene. If you select the optimum of its thickness, then no heat loss will not be. It will be directed exclusively to the base floor in the room to warm up the air.

Modules of the timber may be made of particle board or OSB.  They have special slots for premises pipeline depending on the step,. Plates themselves may have different widths in 13, 18 or 28 cm. All will also be fully depend on, with some steps performed stacking system circuit underfloor heating.

They have special slots for premises pipeline depending on the step,. Plates themselves may have different widths in 13, 18 or 28 cm. All will also be fully depend on, with some steps performed stacking system circuit underfloor heating.

Plates for heat distribution can be made of such metals, as steel or aluminum. Also they have grooves themselves also stiffeners. Using pads fit becomes very dense, that allows you to direct heat over its entire surface and uniformly distributed around the base floor.

Stacking circuit

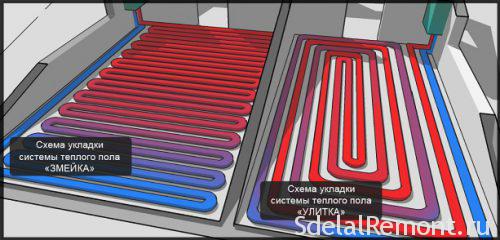

Before, how to perform a warm floor screed without, should make its calculations and draw up a pre-schematic plan. It shows the distribution pipeline. The tubes may be arranged in two basic schemes:

But in a single execution, they are rare. If only way to "snail", when the heat is evenly distributed over the entire surface. Most often arranged combined scheme, when in the same room combines both methods for better efficiency.

Less demand scheme "snake" in the usual standard. It is more suitable for rooms with a small area. The fact, that the warm areas on the floor will be located right at the entrance of the warm coolant, the remaining portion, directed to the outlet, will be less warm. It is best to have to perform a "double snake".

Should think about laying a pipeline stage. He is directly proportional to the selected pipe diameter. You can not take a very small step, if a large cross section and vice versa - for large pipes with a small diameter. Select step can be in the range of 50 to 450 mm. If the load in the room 48-50 W / m2, the optimum step amount 300 mm.

You can increase the thermal load to 80 W / m2. In this case it is necessary to reduce a step for a better efficiency of warm water floor. In the case of large premises and a very high ceiling, the optimal distance between the coils is selected pipeline 20 or 25 cm.

Pay attention, the maximum length of the pipe - 90 m. otherwise you can encounter serious heat losses, and reducing the pressure in the system. For greater length is created in the same room as another circuit. From the walls have to maintain a distance, equal to the step of laying. Normally, it is equal to 30 cm.

The final option depends on the preferences of artist. The main thing to choose a quality warm up the entire room from the floor and to the desired height.

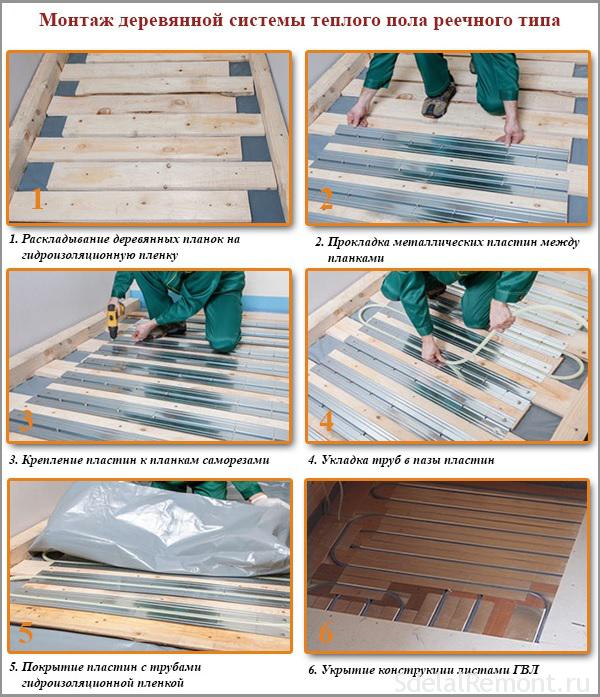

Wooden rack system

This design, for which you are dry screed warm water floor, It is one of the wooden system. The supporting role here belongs to the rails, boards made of. Typical thickness of the material - 20 mm, at a humidity of not more than 10%.

If the selected pitch pipe equals 15 cm, the width of the strips of boards must be 130 mm. When you step in 200 mm - 180 mm, 300 mm - 280 mm.

The strips will be used to support system under pipeline water underfloor heating. Laying can also be performed on the old wooden joists or base. If you run logs, the thickness of the whole structure will be reduced by approximately 20 mm.

Driving system for a wooden rack as follows:

- Produced complete cleaning the surface of debris and, if necessary, qualitative alignment. Per linear meter of the floor is permitted height deviation on 2 mm.

- The polyethylene layer serves as a waterproofing vapor and dry method underfloor devices.

- The side should not stay damper tape, which is mounted on the wall in the room on the perimeter.

- After the distribution of wooden planks on the ground, produce their mounting with screws. The installation should be made across the exposed lag or supporting boards. All must comply with the established plan for the pipeline step.

When the pipe distributed over the surface, they draped the support rails. We can not forget about the gap between them, which must be equal 20 mm. Rods should be possible to round on those parts, where there is a bend tubes water underfloor heating.

When the pipe distributed over the surface, they draped the support rails. We can not forget about the gap between them, which must be equal 20 mm. Rods should be possible to round on those parts, where there is a bend tubes water underfloor heating. - The support plates are fastened with screws to strips of wood. Uniform heating of the subfloor will be reached in the event, when the surface is covered with slats on 80%.

- For acoustic protection film of polyethylene is placed on the resulting construct. During the heating or cooling of the coolant in the pipes will not appear abnormal noise.

- After that can produce gypsum fiber board sheets stacking in two layers it is desirable, bond them together with screws. This layer will serve as a basis for further laying a floor covering.

The modular wooden system

Warm floor under dry screed modular wooden system is somewhat different from the rack. Main here is, that the heating pipes are laid between the rails, and in a special module of the groove, which can be a slab of chipboard, OSP.

All elements are connected to each other by means of locking system. The result is a truly equal basis. The process of installation is not different from the rack Technology. But the work is carried out much faster and easier. No calculations are not made at the expense of, that slots are already available in the purchased modules for sheathing.

polystyrene base

The algorithm to create, if desired, dry screed for warm water on the floor mat polystyrene as follows:

- Substrate Preparation for work, As in the previous system.

- The layout of polyethylene film. Must necessarily be an overlap in 10-15 see if there are several rows. The film thickness is selected 200 md. It acts as waterproofing, protection from moisture.

- Mounting the damper tape.

- Unfolding mats made of polystyrene. Fixing them to each other is carried out using existing locks. If the thickness of the mat small, better reliability for the edge material additionally smeared with glue and fasten.

- Between the mats on the surface protuberances produced stacking metal plates, where laid heating pipes water underfloor heating. At any Scheme tube location will be twists, when they will only lay down on polystyrene mats. In this case, under it is best to put a film of polyethylene, that design does not create extraneous sounds.

- When the whole system is built, additionally laid another layer of the film, then covered all the leaves of horse herpes usually in two layers. The optimum thickness sheets of 1 cm. the main thing in this case - a mismatch between the joints at the device of the second layer. Here it is necessary to lay the sheets in a staggered manner.

If the smooth material used without grooves, they can cut yourself with a special tool - termonozha. Otherwise, it may be called the device, contributing grooving. Subsequently the whole installation process is identical to polystyrene system.

Flooring flooring

When warm floor under dry screed flooring should cover, its version should be designed specifically for the system warm water floor. To this end, it has a special marking, indicating it. But in each case has its own characteristics.

So, eg, for tiles will create a further layer of gypsum fiber boards, are bonded to each other in a staggered manner using glue.

Possible mistakes

At first glance it may seem, that the dry screed for warm water floor is very easy and no complications can arise.  But novice performers may interfere with certain errors, which will result in inefficient operation of the water floor heating. To avoid this pre-should be made calculation of a warm floor, both before the start of work, and after installation. Ongoing measurements may indicate possible errors, which will eliminate the previously better, than to spend more effort and funds. It also carried out the calculation of the pressure on the subfloor.

But novice performers may interfere with certain errors, which will result in inefficient operation of the water floor heating. To avoid this pre-should be made calculation of a warm floor, both before the start of work, and after installation. Ongoing measurements may indicate possible errors, which will eliminate the previously better, than to spend more effort and funds. It also carried out the calculation of the pressure on the subfloor.

Screed perfected should not be heated above human body temperature. There is a maximum temperature, which can withstand normal line, depending on the chosen material. But it is recommended to create an operating temperature of not more than 55 degrees.

Another possible error - installation of temperature sensors in the deep structure. They can not serve as a long time and periodically fail, requiring replacement. It will be very difficult to get them to check on the performance of.

In no case can not be rushed in holding installation of floor heating. Better check each step in the future for a long time to enjoy a quality system operation. Experts recommend that even a few days after work to leave the system alone. That is, it should not be included. When all the elements are clutched with one another, especially if used when mounting glue, you can start to use it.

You can not save money on the purchase of materials, as the system will be a very long time. It is unlikely that someone would want to lay flooring and a year later it had already dismantled for repair of water underfloor heating.