Floor radiators for a long time can not compete for the title of best, since this position is occupied underfloor heating. The latter are able to replace the bulky heating systems and at the same time provide a lot of positive qualities. But in this case, the choice of warm water floors should be understood, that will have to make an effort for installation. Particular attention takes a pipe-laying on the floor, a selection of her particular scheme. No small importance is the pipeline itself, correct his choice, depending on the operating conditions.

The choice of tubes

Before, How to style a warm floor under the screed, should define the list of materials, which will be necessary for a quality installation.  You can not save, and buy the best products from a decent manufacturer, based on the feedback and characteristics. Some manufacturers may give a guarantee on its products in more than 30 years old. This is exactly what you should pay special attention to. Indeed, in cases of marriage or any faults in the operation of warm water floor, they will be required to pay the entire compensation, offset the cost of the goods.

You can not save, and buy the best products from a decent manufacturer, based on the feedback and characteristics. Some manufacturers may give a guarantee on its products in more than 30 years old. This is exactly what you should pay special attention to. Indeed, in cases of marriage or any faults in the operation of warm water floor, they will be required to pay the entire compensation, offset the cost of the goods.

Laying process may be complicated by the presence of corners pipeline, which can vary from 45 to 90 degrees. In addition to water pipes warm floor must meet the following parameters:

- Long life.

- strong design.

- Ability to withstand high temperatures up to 120 degrees.

- wearing qualities.

- Gay water and other possible coolants (antifreeze).

- The high degree of heat.

- Low levels of expansion under the influence of heat.

Popular with all the diversity of the materials are made of metal or polyethylene tubes.  This is due to the rather low cost of production in comparison with other types of (stainless steel, copper), and excellent performance. They are able to demonstrate all of its properties under all conditions.

This is due to the rather low cost of production in comparison with other types of (stainless steel, copper), and excellent performance. They are able to demonstrate all of its properties under all conditions.

The ideal pipe - this is, which is not subject to cracking, which is very important in the process of carrying out installation work on the loop device warm water floor. It also can be mounted even in air at a temperature +5 degrees. The outer diameter of such a tube may be from 9 to 22 mm, that is aligned with the internal cross-section. This all does not affect the bandwidth.

Scheme stacking "snake"

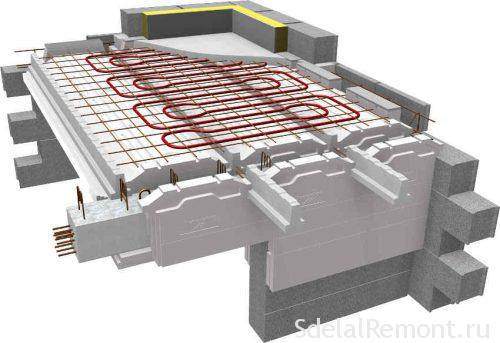

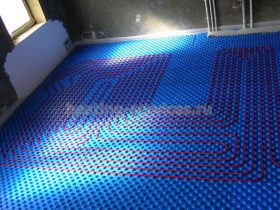

Prior to the start of pipe laying underfloor heating water type should think about the foundation. It should be qualitatively prepared, so the whole system can be installed only on a flat surface, which leads to the manifestation of all characteristics during operation. Therefore it is very important to align the screed floor heating in all technology requirements.

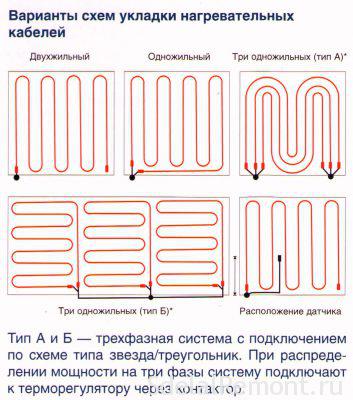

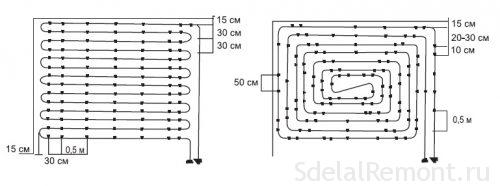

There are several options for laying pipes on the floor for subsequent heating. Among them are beginning to consider scheme, became known as "snake". But immediately it should be said about the great heat loss by using schemes. After the water supply into the conduit is only one portion. While the rest coolant will reach the final element, He is very cools. Consequently, towards the end of the scheme laid subfloor will not be warm. Hot surface is obtained only at the output of the hot coolant.

The disadvantages of this scheme can still carry and difficult assembly process. There will need to produce bending of the pipe at an angle of 180 degrees, that can sustain, not every material. In this case, markedly increased laying pitch pipeline, which can reach up to 20 cm. In such a step also large areas of with lower temperatures will be created base. Conventional pipe will not be able to transfer heat to a distance.

More time-consuming process - creating rings in the field of bending pipes. It gets rid of the angle of the fracture material. In this case it is best to resort to professional help, who will perform all the work and in time. In addition, they will be able to avoid installation errors warm water floor. Do not be amiss to pre-calculate the device water floor heating, to learn about all the costs.

To reduce the temperature differences throughout the entire area of warm water floor, It carried out a so-called double "snake". Then only increased the complexity of, but the subfloor will be much warmer than in the previous consideration of options.

With regard to the application of such a scheme styling pipe sex, the more it is suitable for small areas of premises, when aligned adjacent zones contours, sanitary facilities, when there is a serious circumvention of the various instruments (toilet, plumbing, etc.). But even in the latter case, when a square 6-8 m2 it is best to have in fact applied a helical system.

"Scroll" apparatus pipes

Otherwise, this arrangement is called spiral duct. It is selected and executed until, be realized as a device screed underfloor heating. The popularity of the scheme lies in the economy, the efficiency of the entire system of warm water floor, as well as better energy transfer based on sex in the room.

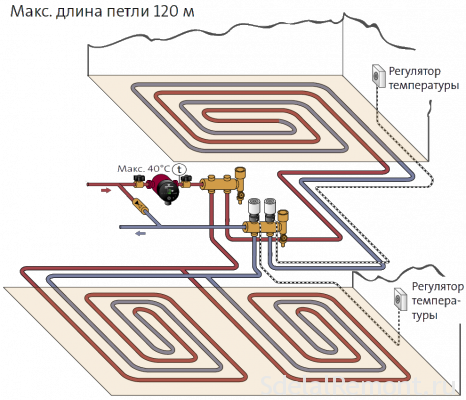

When a blow underfloor heating snail, tubes are, describe the perimeter of the room. The beginning comes from the edges, along each wall and sent to the central part. The radius of the pipe laying on the floor in this case is reduced by close to the center. After that, both reached the middle of the room, similar operations are repeated in reverse order to the edge. From this immediately follows the main advantages of the chosen scheme - the uniform distribution of heat on the ground floor in the room. The floor does not constitute areas with low temperatures, as the conduit rotates hot coolant supply (seeking) and cold (leaving).

Minimum mounting pitch is 10 mm, all other parameters are selected based on personal preferences. But it is worth noting, that the smaller the step, the more the material will go for circuit assembly warm water floor.

"Snail" - not only the most reliable, but also the working scheme. The process does not take much time and effort, as the pipe bend very slightly. This process after reading the installation technology, can fulfill even one person on their own without the involvement of experts and spending them funds.

Using helical circuit pipe-laying on the floor, can produce insulation of individual sections (near the outer walls or windows). All the heat starts to be transmitted to humans, Only when he is on the floor in the room at the entrance.

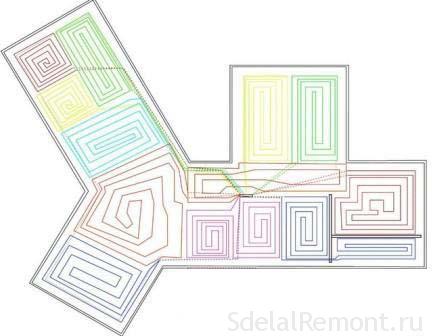

any premises, with any configuration, variety and large areas can be equipped by the scheme conduit arrangement warm water floor. The turns of "snail" can be done not only through the room, but obvode gromozdkoy furniture, which will only harm the circuit during operation. In any case, the power of the pipeline will be sufficient for heating the subfloor in any room, as well as the height of the air to 2.5 m.

combined option

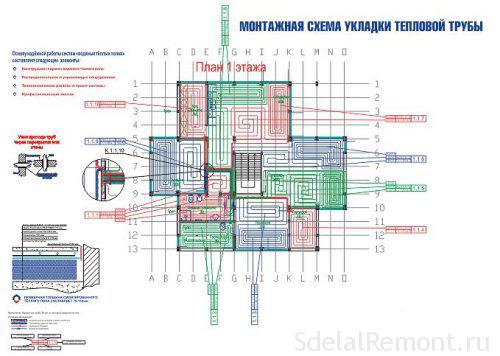

When it is determined screed unit underfloor heating, just "pie", you can try to calculate not separate the pipeline laying scheme, and some of their options in the same room. Further mixing may occur duplication separate embodiment: snail is two turns or more snakes. This should allow the layout of the premises to perform such manipulations.

All useful energy in the ground should be concentrated in the central part of the room. It is here that you can think of pipe laying scheme "snail". On the remaining areas will be sufficient and the snake, To get a high-quality heating. The situation is similar to the individual sections, such as exterior walls, when to think about their insulation.

Combine can not only schemes, but also the types of underfloor heating. Water embodiment can be combined with excellent electrical, and be interchangeable. This is particularly true in the summer, when you do not include central heating, You need to waste electricity. All this is created for comfort and relaxation in the living room.

In each situation, you should try yourself calculate a warm floor and make sketches on a sheet of paper. This will help you to choose a specific option for execution.

boundary zone

Laying of heating floor in mortar requires special attention in the edge zones. They are also called boundary. They are located near the outer walls, that border the street, window and door openings. It is better to choose the smaller step of laying pipes, to increase the concentration of high temperatures. If a, eg, in other areas is taken a step in laying 100-150 mm, it must be doubled for the lower marginal zone - 50-75 mm.

When using the "snake" scheme should be made closer coils itself around these areas in the room. Another option - Corner snake, to collect basic heat mass is about the boundary areas.

The most important thing in this situation - to create the conditions for the proper level of temperature indoors during use warm water floor. In this will affect the chosen scheme of laying a pipeline under screed, as well as the selected step.

Optimal step

Before, how to put in a warm floor screed, and a selection circuit for mounting pipe, it is necessary to choose the best of the last step. Step - distance between adjacent turns. It must correspond to the selected diameter tubes in appropriate proportions. If the cross-section of a very large, it makes no sense and efficiency to take a small step pipe laying on the floor. The same applies to the large distance between the coils of pipes of small cross-section. The main consequences of such errors - thermal voids or overheating of the base.

Preferred step selection indices - 150-300 mm. If it will increase, Consequently, It should rise in the temperature of the coolant system.

Much will depend on, what meant the room. If the heating system is to load 50 W per m2, the step must be selected 300 mm. Higher system load (from 80 W / m2) require a step to reduce 150 mm. This solution is best suited for bathrooms, when the temperature conditions should be stable.

step in 200 or 250 mm suitable for large areas of space, which also has a high ceiling.

There is such a thing, as a variable pitch, when the pipeline reduces the distance between the coils at selected sites, which may be the boundary. About them we talked about earlier. Rapid step will be approximately 60% from optimal. Rows should be calculated on the basis of the parameters of the premises, where the works.

The parameters for calculating

when necessary laying of floor heating under the screed, should calculate a set of materials, that may be required. This is affected by certain factors, which include:

- area.

- Used for heat insulation systems of warm water floor.

- acquired boiler, its capacity, temperature readings.

- Material, used to perform the walls, overlap, as well as thermal insulation.

- The diameter of the pipeline, and selected connection it is laid on the floor.

- Chosen flooring.

It all points to the length of the entire tubes, which would be necessary for the underfloor heating system installation. No small importance is and "route" stacking, space reduction step or larger. the main thing, to end up warming the subfloor was uniform over the entire area.

When completed the installation of floor heating circuit water type, will only align screed floor heating and to produce flooring of any kind flooring. true, it is worth noting, that the coating will depend on the floor certain nuances device of the system of warm water floor.

findings

Few know about, Do screed need under floor heating. This is a must, if the base has various defects such as cracks, potholes, protuberances and other irregularities. Piping hot water floor system must necessarily be laid exclusively on the flat surface.

When you select a scheme, It should focus on the area of the room, as well as the presence or absence of the edge zones. It is important to know the whole budget, which emphasizes the choice of pipe materials, as well as their number. But it's best not to save and make installation of high-quality design, which will last for a long period.