Warm water floor rapidly crowding out the more classic versions of premises heating. This is due to the positive qualities, which manifest themselves in the process of operation of the system. All of them can be arranged in different ways, depending on the chosen technology. "Classics genre" is the installation of floor heating water, followed by pouring concrete mortar.

Advantages of floor heating

Technology laying of floor heating Water has a set of advantages, which include:

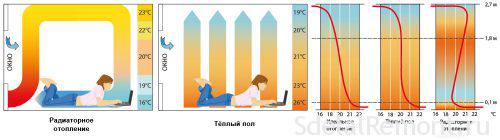

- Comfortable conditions. Heat in the room is evenly distributed and the entire area. There is no almost no heat, that allows you to save on heating payment. Practical embodiment is well-known expression "keep your head in the cold, and the feet warm ".

- economy. It is becoming heated space in the room, except under the ceiling portion. The floor surface in this case does not absorb the heat, but rather gives it. If you are mounting in a standard room, the costs are reduced by about 15-20%, and if this is the room with a high ceiling of more than three meters - up to 50-60%.

- The high level of adaptability. From the radiator heating system can be arranged underfloor heating system. In addition to a single room can be arranged all around the house (for apartment buildings such options floor heating are not provided, except for buildings, where it laid the basis for).

- When a conventional radiator heating convection always faced with moving air mass. This is all due to the presence of dust, in the suspended state. Warm water floor also does not create such an effect, uniformly heating occurs and dust is not moving air masses. Of great importance it has in the children's rooms, especially when teenagers suffer from various diseases, propensity to allergies.

- Long service life. Much in given case will depend on the material used for.

- Easy installation. many will say, that not everyone here is so easy to perform. The most important thing - to create the project and display the entire work plan together with the scheme pipeline on paper. In the following will only have to transfer all this on the basis of sex in the room.

methods device

Screed Warm water floor heating - a layer of concrete, which may be arranged in two basic ways:

- Using the special building dry mixes ready-made.

They were in a huge range can be found in the construction market. In addition to them, various additives are applied, giving the best quality of the future solution.

They were in a huge range can be found in the construction market. In addition to them, various additives are applied, giving the best quality of the future solution. - Mixing your own cement screed with M150 brand of cement and up with the addition of PVAc ductility and reliability of the whole structure.

floor heating technology allows you to make a choice in favor of one or another way. The main thing to adhere to the established rules and recommendations of the manufacturer. If a ready mix and everything is clear - there is enough to add a certain amount of water to produce a fill, the independent preparation requires careful and strict observance of proportions.

Not everyone knows about, how to prepare the grout concrete screed. The proportions will depend not only on the cement grade, as well as the use of alternatives instead of sand. As for the adhesive, the 1 kg will be sufficient for the entire bag of cement. Main add the right amount of water, to the solution was appropriate consistence.

Design and selection of thickness

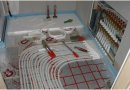

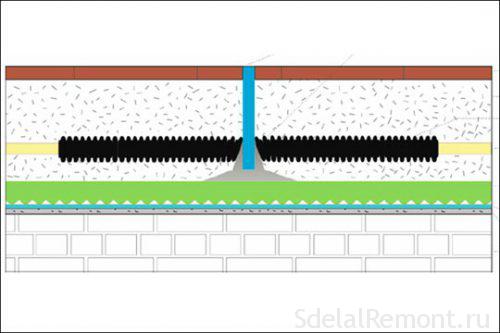

More often installation of water floor heating under the screed is carried out on the old base, to travel along which a layer of insulation. The main requirement is to prepare a base for the installation carried out. After all, it must be perfectly flat and without errors. Allowed only minor differences in the level of the height of the room. Insulator layer in the form of a tube or penoflona foil is compulsory, regardless of, water or electric floor heating It is arranged in the room.

The next component of the whole structure of warm water floor - laying the pipeline. It can be mounted directly onto the prepared substrate, on the mat, is attached in the reinforcement layer, or placed in special mounting mats with grooves. In the latter case, the stacking process takes considerably less time. The final decision - pouring concrete screed. The resulting cake will be able to fully warm up the room from the base, evenly distributing the temperature.

It should be understood that, that the whole structure must have Optimal parameters of height. Each layer "cake" has its height, which would be necessary for the quality of work of the water floor heating system type.  When it comes to concrete screed, then its optimal height is 40-60 mm. All will depend on the type of mixture, space mission, and the presence of the reinforcement layer or lack of. Have greater flexibility self-leveling mixture, which also allow without a layer of reinforcement to arrange a thin screed over underfloor heating to a maximum of 20 mm. In this case, the solution is added a universal plasticizer or other additives. Technology laying of floor heating water type provides competent distribution of the height of each layer relative to each other. If done efficiently and with optimal parameters, the system efficiency is the highest.

When it comes to concrete screed, then its optimal height is 40-60 mm. All will depend on the type of mixture, space mission, and the presence of the reinforcement layer or lack of. Have greater flexibility self-leveling mixture, which also allow without a layer of reinforcement to arrange a thin screed over underfloor heating to a maximum of 20 mm. In this case, the solution is added a universal plasticizer or other additives. Technology laying of floor heating water type provides competent distribution of the height of each layer relative to each other. If done efficiently and with optimal parameters, the system efficiency is the highest.

necessary purchases

That was made installation of water floor heating under screed, you must purchase the necessary materials. The most basic - the system components, which includes a pipe, heating boiler, collector group etc. Under it is required to lay the thermal insulation layer. Insulation may be used in various, but the final layer thickness It should be within 80-100 mm.  Only in this case, even the basement no heating will not allow heat to take his side. It all will be sent to the subfloor in the room.

Only in this case, even the basement no heating will not allow heat to take his side. It all will be sent to the subfloor in the room.

For screed You need to purchase materials in the form of sand and cement for solution, or premixed, which greatly simplify the whole process of filling. The cost of the additives in the solution is not high, but they significantly increase the reliability and strength of the whole structure.

In addition to this, you can think about, to hire a team of builders for work. But in this case, should be available funds to pay for their services. The most important thing, that in the end will turn out high-quality and efficient system design warm water floor.

Substrate preparation

Technology laying of floor heating requires a thorough preparation for the installation of surface. originally arranged capital tie, allowing smooth all irregularities in the substrate. This is especially true for applications with large height difference.  If you do not, will form air pockets, affecting the water warm floor system. After that the installation of additional layers, contributing to the improvement of system performance - heat, Hydro and vapor barrier. They may be applied as a film of polyethylene, waterproofing mastic, insulation of foamed polyethylene, etc..

If you do not, will form air pockets, affecting the water warm floor system. After that the installation of additional layers, contributing to the improvement of system performance - heat, Hydro and vapor barrier. They may be applied as a film of polyethylene, waterproofing mastic, insulation of foamed polyethylene, etc..

All components must be positioned correctly relative to each other. In such a case stacking technology water underfloor heating under the tie will not be broken, Consequently, you can get all the positive qualities and characteristics during operation. Even the pouring process will not create difficulties due to poor foundation, the quality of its preparation.

Laying the pipeline

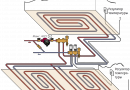

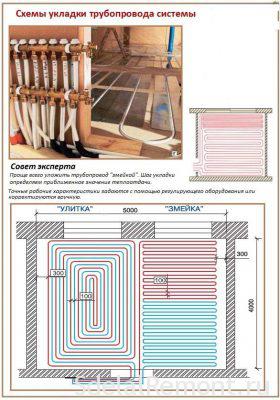

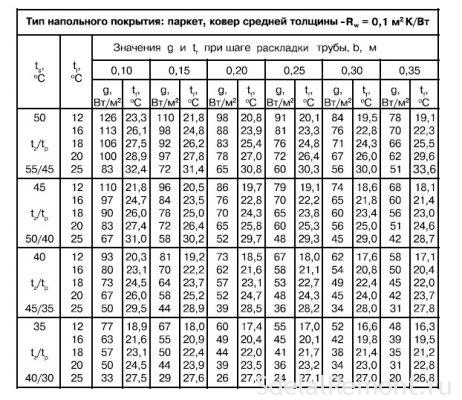

If you strictly follow the technology of laying the water warm floor under the screed, then stacking up pipeline measurements should be made literate and plan diagram. At the last location is displayed with the selected pipe step and circuit stacking. There are a variety of computer programs, allows the user to manipulate a lot easier and better. For this purpose there calculation of a warm floor.

The scheme on the scale relative to floor space, transferred to the heat insulation layer. When the mats under floor heating have special grooves for fastening pipes, the pre diagram rascherchivaetsya. To do this, you can use a regular marker. Additionally, this method allows to identify possible errors, which were not detected in the design of the scheme.

The pipes are properly secured, You can select one of the possible ways:

- Using Wire mesh, which carries the circuit.

- polystyrene plates, designed for warm water floor. They have special "boss", staggered. Between them and the fixed pipe.

Selection step pipelaying

When the layout of the pipes most important thing is to calculate everything, and only then realize. Before laying pipes must make a connection to the supply manifold, made directly to layout pipe on the surface of the insulator, after which the remains of circumcision unnecessary portions are connected to the return manifold.

It should be remembered about the choice of pitch pipe laying. You can not take a small step, if a large cross section and vice versa - for large pipes with a small diameter. There will overheat divided portion or thermal pits appear. When you create a load in the room 48-50 W / m2, the best step is to 300 mm. At higher loads up to 80 W / m2, pitch is halved to 150 mm.

Thus the maximum path length should not be more 90 m. Otherwise, you may face serious heat losses, and reducing the pressure in the system. If you need more length - it is necessary to create an additional circuit, even in the same room.

test event

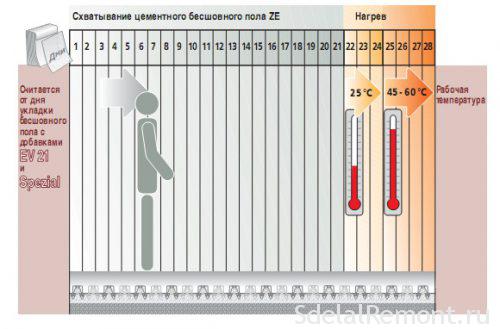

To get a quality installation of warm water floor in the screed, should test the system after laying the pipeline and connecting it to a collector. Checks sealing compounds and individual sections tubes, located in the future screed.

The system is filled with water or a special coolant, such as antifreeze. If the room there are several circuits, they shall be filled alternately. Opens one circuit, filled with water, removed air, after which he closes, and similar actions are carried out with a second circuit. When all circuits, they close, and pressure is applied to the system, amounting to 4-5 have. It then increased to a standard in 1.5 fold. system of work should continue for two hours, then switched off and left still for two hours. Such actions are typically repeated 3-4 fold, to make sure, that everything is working properly.

After that the working pressure in the 2-3 bar and does not turn off during the day. In the presence of water leakage will decrease the pressure in the system, antifreeze - a specific smell. In the latter case, we must be careful, since part of the coolant includes glycol, which can lead to the poisoning of its vapor.

All of these tests on the technology of laying floor heating in the screed should be carried out without fail before solution casting. If you pass the stage and start to distribute the solution, to create a solid structure, the last will be much more difficult to identify errors and areas of breakdowns.

screed

Laying of heating water floor in mortar begins after all the previous stages in a clear sequence. Initially occurs solution preparation. Instead, the reinforcement layer is applied such an additive, as fiberglass, even having the best qualities and properties. Along the perimeter of mandatory laid damper tape, promoting preservation screed when thermal expansion.

For floor heating technology screed thickness over the top of the pipeline must be 40-50 mm. The solution is poured onto the substrate and evenly distributed over the entire surface. Start all the work from the far corner of the entrance to the room, and is contracted to the entrance. Do not be amiss in this case to use the beacons to quality casting.

thin strainer will warm up much faster, but it may result in fracture, as well as the appearance of the effect of "thermal zebra", when you can feel on the surface laid conduit.

To increase the efficiency of water warm floor system, should provibrirovat surface, that will get rid of air bubbles. In this case, the concrete itself will be tight to the pipes.

To a flooring floor covering can begin only after, as concrete screed completely dry.

An additional calculation of the thermal mode is made if the tie more 150 mm. But once you can face some difficulties in heating subfloor.

Expansion joints

That the solution could not be destroyed after casting and during operation, must be respected stacking technology warm floor under the screed. It is mandatory after casting must be made expansion joints under the following conditions:

- A large area of the room (over 25-30 m2).

- room configuration is very izgibistaya.

- The length of one wall over 8 m. The difference here between the length and width of more than 2 fold.

- For structural expansion joints.

water floor stacking technology provides for the separation of the entire room with its large parameters at separate sites, and where the seams are arranged to preserve the integrity of the tie over the warm water floor. The best thing to do to pick the prime elements in the form of a square or rectangle.