Radiant floor heating radiator is much preferred. But it is worth noting, that its installation should make a great effort. Particular attention should be paid to the material for solution for pouring water over the floor pipes, and most coupler. It is important here to comply fully with stacking technology, to achieve the desired result. In the allocation is pre-defined with a solution, which screed thickness will generally be and what goals it pursues. All pipes and efforts will be in vain, If you violate the basic requirements and recommendations for installation work. Moreover when the warm water floor working device, of you better show your competence, so they can not cheat.

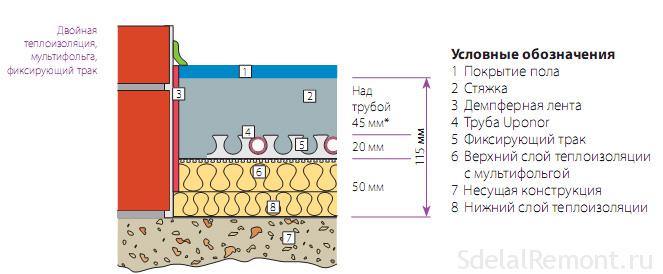

designation

Ties warm water floor needed, to create a protective barrier for the entire circuit system from external influences. In addition, it is possible to put different communication, so they do not spoil the appearance of the premises, where the works.

Pouring water underfloor heating It may be configured in several embodiments, each of which will differ from each other in thickness. In some cases it will be enough and thin ties with minimal parameters. But then there should be weighty loads on the substrate. Otherwise, it will not be able to fulfill its mission.

each species flooring It requires a certain quality of the fill and some subtleties installation of warm water floor. It is worth to pay attention to pre, even when carried out purchase materials. You should also know that, Pour than warm water floor, how to use this component.

The flood?

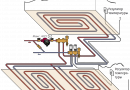

TO warm water floor screed come then, when it made laying the pipeline system. Here it is worth considering two main options, both underpour. Ways there are in each of them several different components, of which will be made kneading solution:

- Concrete screed. The basis of the solution - cement.

- Polusuhaya screed. finished building dry mixes used to prepare a solution, in which it is enough to add a certain amount of water.

They all have their good qualities and cons, that may be encountered during the preparation of the solution. For the final choice should be weigh the "pros" and "cons". Features of each option can help make the right choice in favor of fill.

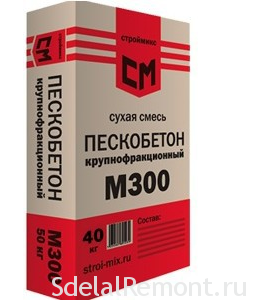

The most popular ready peskobeton M300.

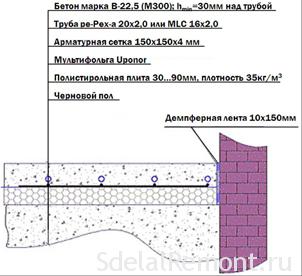

In addition to the concrete mortar is best to add plasticizer, improves durability of the whole structure after fill screed a warm water floor. In this case, the latter in the operation will not crumble. His number - about 0.6-1.0 liters per m2 poured Square. It may be noted, that the thickness of the screed in such a case will be reduced until 30 mm. A similar capacity for the same screed concrete without plasticizer commensurate with a thickness 50 mm.

Some are concerned about how, possible to fill the water floor heating device without reinforcement layer. In this case it is necessary to begin to define, what kind of room in front of us. If the area above the room 40 m2, and also has a complex configuration, as an alternative to the metal mesh can be used fibrovolokno, constantly gaining popularity among the warm water floor performers. addition fiber It provides the ability to evenly distribute the solution in the process of filling, while maintaining all the qualities, necessary to maintain the strength of ties.

Prior to distribution of the solution should be to identify areas with the location of expansion joints. They are necessary to compensate for thermal expansion. Concrete will retain its original appearance for a long time. The site possible calculate the amount of concrete screed calculator online.

Events to fill

Before the start of preparations for device ties warm water floor should undertake other jobs, such as plaster walls in the room.  You should also install windows and doors in the room, to lay all the possible communication (electrical wiring, sewerage, plumbing and TD). The entire surface for subsequent Warm water system laying floor It should not only be smooth, but also very clean, without defects.

You should also install windows and doors in the room, to lay all the possible communication (electrical wiring, sewerage, plumbing and TD). The entire surface for subsequent Warm water system laying floor It should not only be smooth, but also very clean, without defects.

There may be cases, when the plaster walls in the room was made after pouring concrete solution. In this case, the surface is cleaned by a solution pieces. For this purpose can be used BSL. To plaster missed the subfloor, it is possible to lay a film of polyethylene.

Between the walls and the base angle must be maintained in 90 degrees. Otherwise not be able to achieve a snug fit for a warm water heater floor to the walls and surfaces.

In one circuit arrangement indoor surface level is allowed discrepancy, but not more 5 mm. Otherwise you can encounter with the deformation pipe and the appearance of air pockets. If you use the proprietary damper tape, which has a layer of adhesive for wall mounting, the part of the wall at a height of about 40-50 see proshpaklevat. This will improve the quality of the tape fixing.

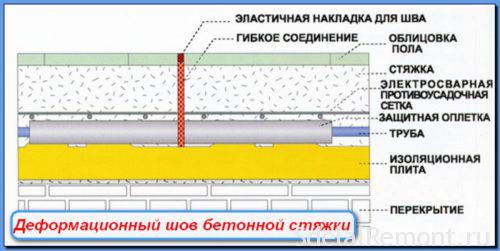

Expansion jointing

If you are not rough, but fine finish subfloor along the contour of the heating system, should perform expansion joints. The same applies to rooms, having a large area more 40 m2.  To be safe, the seams are performed every 20 m2 room area. They do not allow the screed to crack because of the constant fluctuations of temperature. Rough screed avoids such events, since between underfloor heating and it is a layer of insulation, allowing it to avoid.

To be safe, the seams are performed every 20 m2 room area. They do not allow the screed to crack because of the constant fluctuations of temperature. Rough screed avoids such events, since between underfloor heating and it is a layer of insulation, allowing it to avoid.

Where are arranged seams, Floor water pipe must pass in ripple. Its diameter should be slightly larger, than that of the pipe itself, to better and easier to put on her. There are enough circuits, pointing to the correct and incorrect placement of expansion joints indoors, which is carried out screed on the underfloor heating system on the pipeline.

Selection of the optimal thickness

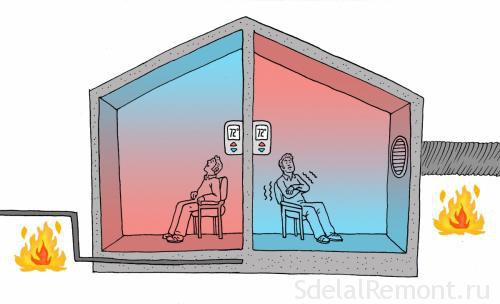

The thickness of the screed underfloor heating is essential. After all, the layer will depend not only on its durability, but also the efficiency of the room heating. Too thin screed quickly crack due to the effects of temperature and even normal walking. But a thick layer will not bring any desired results - warm floor will spend a lot of energy and resources for heating the whole "pie". Consequently, significantly increase waste on heating payment, that can be read calculator on heating costs.

The optimum thickness Concrete screed is 50-70 mm. If instead of the reinforcement layer to take and add fibrovolokno, it is possible to reduce all to 30 mm. The same applies to the use of different plasticizers. They may be packaged with the acquired dry mix.

We can not forget about the fact, except that it can be used in the apparatus for screed water underfloor self-leveling mixture. In such case the layer may be only 20 mm, and the strength is sufficient to withstand severe stress on the surface.

A particular embodiment of the fill and the choice of optimal thickness tie layer will depend on the particular situation and customer requirements. Approach to this stage should responsibly, warm water to the floor as the main heating system of the house could serve as a possible long-term.

Topping a beacon

After the test activities on health underfloor heating systems water type, you might think about the immediate filling. According to the level previously exhibited beacons. But as such their name very seriously, as they are represented in the form of conventional mortar slides, to which is fixed a metal profile.  Solution for the beacons can be prepared from alabaster, concrete. Do not be amiss to pre-erect formwork, so they will not melt in the process fill. the main thing, that nothing is placed on the floor of the water pipeline.

Solution for the beacons can be prepared from alabaster, concrete. Do not be amiss to pre-erect formwork, so they will not melt in the process fill. the main thing, that nothing is placed on the floor of the water pipeline.

Thereafter, should produce a uniform distribution of the solution over the floor surface with the pipes. For this perfect rule, allowing to pull it in a selected direction. Fill should start from the far corner of the room, to subsequently distributed not walk on the solution surface.

This concrete pouring technology of warm water of sexual identity, not only for roughing screed for laying contour, but also for the finishing of the pipes. It should be observed, and do not stand aside, even in case of doubt. The practice has developed over the years and that is how it turns out really good result.

We can not forget about the concrete rammer. This makes it possible to expel from it the air bubbles. If you do without this event, in the subsequent significantly reduced thermal conductivity is filled screed. When there is no self-confidence, more profitable to seek professional help, than to alter and dismantle the entire floor construction.

Polusuhaya screed

Once configured assembling heating circuit, possible instead of concrete fill underfloor choose their own hands semi-dry screed. Fastening pipes must be reliable, and necessarily arranged damper tape around the perimeter of the room.

But how to pour a solution of warm floors in the given situation? The sale is a large amount of dry pre-mixes, in which we need only add a certain amount of water.

pouring process differs little from a concrete screed. You also can not do without lighthouses, if you want to get a flat, horizontal surface. In the process of filling pressure pipeline It must be raised to 0.3 Mpa. Defined between beacons distributed mixture, which is mixed with water. The layer thickness of the fill tube should always be kept under control. Minimum level should not be lowered below 30 mm. This distance is measured from the top of the heating surface. Stacking produce solution, wherein substantially less water, than concrete screed, should be evenly and tightly as possible. In the formation of the space under the rule in the distribution of the mixture, there is added the right amount of it and re-produced distribution.

Grout required solution, and should be carried out after about half an hour after the final filling mixture. Work can produce materials at hand, or use a special trowel. That it does not acquire for a one-time performance screed assembly, easier and more profitable to rent for the duration of the works. If you miss out on the half hour, who put, it will be much more difficult to produce grout. Full grasp mixture is 6 hours. After this time, it makes no sense to make the grout surface, since any result she was unable to bring.

Fully include heating can not until, while the semi-dry screed will not be dried completely. Subsequently the first time the system must not keep the temperature more 25 degrees. The next day there is a temperature rise of 5 degrees, etc., until the full operation of the warm water floor.

this option screed has some advantages compared to concrete:

- Lower cost, than ready-mixed concrete.

- the drying process takes much less time. Also, the setting process is reduced. Within 6 hours you can walk on the surface without fear.

- At the end it does not need to make additional leveling base, as the surface becomes horizontal level.

- No cracks formed after drying, as well as areas of subsidence. And any other defects ties almost never happens.

- The probability of the water flow on the downstream floors minimized, because it is used as part of a much smaller amount of water.

- Increase the heat and sound insulating qualities due to the porosity of the entire structure of the screed.

Contraindications

There are certain requirements, as a general should not be made to fill the screed floor heating conduit. When using a conventional cement-sand mortar, then no efficiency, it can not bring.

We must not forget to perform all the steps of the device of warm water floor, especially the installation of the screed. Here, all relying steps must attend mandatory - heat and waterproofing, insulation and other elements. Strongly do without fixing the damper tape. Otherwise, the service life of the floor heating, or rather above it ties, It is not great.

When the device beacons all measurements need to be calculated several times before the final version. Do everything strictly by the level of construction. Marks will not be enough on the walls. Under them should be tailored to the lighthouse itself that, How to make laying of the metal profile.

Avoiding ties

Some are thinking about, how to do without such a process, as a floor screed. And there is one very effective solution - grazing system.  Warm water floor laid in special metal plate, then immediately begins decking flooring. Only we must not forget, that should be between the two components put moisture proof mat as polyethylene or other alternative material. Everything will depend on the financial capabilities and preferences. In any case, all can be found in the range of the construction market, including dry ready-mix for moist variant.

Warm water floor laid in special metal plate, then immediately begins decking flooring. Only we must not forget, that should be between the two components put moisture proof mat as polyethylene or other alternative material. Everything will depend on the financial capabilities and preferences. In any case, all can be found in the range of the construction market, including dry ready-mix for moist variant.

Each of these options, be it concrete screed or semi-dry, or "dry" method, They have their positive qualities. What to choose in each case - a decision the Executive. The most important thing, that in the end we got a really high-quality design of warm water floor, made in strict accordance with the technology.