Radiant Floor creates comfort in each room, which made its installation. Technology device includes sequential steps of, each of which must go sequentially, to achieve the desired result. Prior to the beginning of work to better understand all the subtleties and nuances, that will be faced in the implementation of installation. But even all this leads to a lot of positive qualities, allowing to take Radiant floor in high regard in the choice of performers.

Materials and equipment

Initially, you should consider visiting the store to buy all the necessary materials for floor heating. Each layer of the structure and the step of work requires a different set of products, allow you to create an excellent heating system in the house when installation of floor heating their own hands.

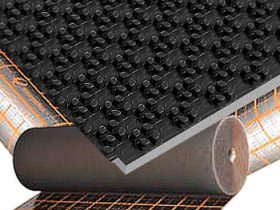

For a layer of insulation more interesting laminated mats made of expanded polystyrene. The thickness can be selected at the discretion. If they are used in the work, the degree of heat will reach the maximum value. No heat loss in the downstream floors will not happen.

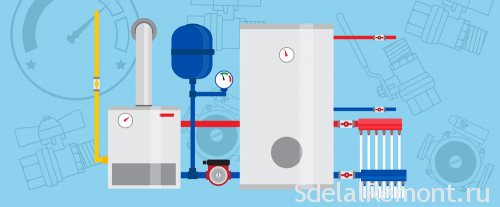

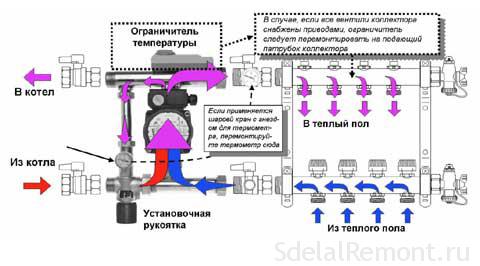

The entire system concrete water underfloor heating It consists of a collector, which is placed in the collector cabinet. The cabinet has a small size, depending on the number of contours, allowing it to seamlessly built into the wall in the room. In addition, they may be external.

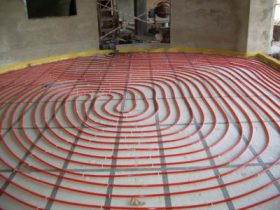

the heating surface is made of specially selected tubes of different material, to which are attached fixing (mounting brackets, locks, anchors, etc.).  In the latter case, all will depend on, what exactly tubes will be recorded. As one of the embodiments - for the reinforcement steel mesh, which can be installed under the pipeline for its fixation, and on top of it for increasing reliability level.

In the latter case, all will depend on, what exactly tubes will be recorded. As one of the embodiments - for the reinforcement steel mesh, which can be installed under the pipeline for its fixation, and on top of it for increasing reliability level.

Concrete screed under warm floor water with their hands except ready-mix may include supplements, plasticizers, prepared solution giving the best quality. The solution can be prepared independently of the sand, cement, plasticizers. The most important thing in this case, strictly adhere to the proportions of adding each of the components.

Supply of heat and heating of the coolant is performed mounted boiler. It is not uncommon to connect the water floor heating to radiator heating, which is already installed in the house.

In addition, it is worth thinking about pre, which option to choose a floor covering for flooring. After all, the process will depend on it installation of underfloor heating in concrete screed. Most preferred - laminate, ceramic tiles.

stacking technology

Not so long ago, as the core technology performance water underfloor heating was concrete. There was enough to pour the solution over the pipe and wait for complete drying.  But progress is allowed to use one semi-dry screeds, which is so called because of the lack of water in the installation process.

But progress is allowed to use one semi-dry screeds, which is so called because of the lack of water in the installation process.

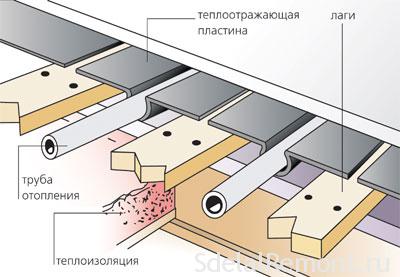

"Dry" installation of water floor heating own hands implies a system of pipeline space on the mats of expanded polystyrene, or in the grooves of wood boards. In a particular case, the tube is firmly fixed on the basis of, protected from external influences. Wooden way to the device floor heating and has its sights set:

installation process does not take very much time and in every situation is not much different from each other. Thus it is possible to mention the most important quality of application "Dry" method, apparatus - quick installation and start of the deck flooring. Once laid out mats or plates, fixed tube with the selected stacking step, it remains only to lay a special substrate, which will protect the entire structure of a possible ingress of moisture and produce flooring selected option floor covering.

Substrate preparation

Pipeline water floor heating system only has to fit on a flat surface. For this reason, it should be carefully pre-prepared base, remove all irregularities, elevation, as well as to cement the cracks and potholes.  When the roughing is executed if necessary screed, We have to wait a while before it is completely dry, then remove any debris from the surface and dust.

When the roughing is executed if necessary screed, We have to wait a while before it is completely dry, then remove any debris from the surface and dust.

The most important event in the preparatory phase - design and preparation of layouts pipeline. some deem, it's a waste of time. But if you take a piece of paper and a scale on it to place all the furniture, which will in future be located in the room, reflect other aspects (exterior walls, installed windows and doors), it is possible to find problem areas, which will require more heat. Besides, immediately affected areas, where harm will be laid pipeline. After all, under a cabinet or other bulky furniture there is no need to lay a path for heating. Heat will only be spent without recoil. In this case, a high probability of failure or damage to the individual portion of the conduit due to overheating.

thermal insulation

When the base meets all the requirements for future Mounting water underfloor heating, can produce flooring insulation layer. It should be made compulsory, if you want to get all the heat inside the room.

Under a further special arrangement of the pipes of a dense foam mats stacked in the room. Its thickness is usually minimal 50 mm. Also it can be made of special film for packing insulation, or various shaped insulating panels. by the way, recent, intended for system water floor. Therefore, they have special projections ("Lug"), which can be placed with a selected pitch pipe. This significantly reduces the time available for work. Moreover, such plates are immediately waterproofing coating.

When using the foam, it should cover the top of the polyethylene film as a waterproofing. The area of the layer located insulation It must comply with the area of the entire premises, where held device of warm water floor.

When using the foam, it should cover the top of the polyethylene film as a waterproofing. The area of the layer located insulation It must comply with the area of the entire premises, where held device of warm water floor.

Along the perimeter of the room along the section, where it will touch the walls screed, mounted damper tape. It prevents damage to the fill layer due to thermal expansion, which can not be avoided when operating the heating system.

Selection of piping circuit

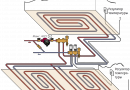

Pipes underfloor They can not be located randomly throughout Substrate. For high-quality space heating should be selected appropriate their an apparatus warm concrete floor, which can be:

- "Snake". In the classic version is the least effective of all the options presented.

The greatest subfloor heating will be carried out directly from the coolant outlet, because there it is hot. But as we move through the pipeline, it will be cool, that will cause, that the portion near the inlet for coolant postheating, will have a cool surface. To avoid this error have learned to arrange double snake, in which portion there is an alternation of hot and cold streams. mounting process has high complexity largely due to the fact, that have to create very large angle of the pipe bend. But here, craftsmen found out - creating loops on a bend. Work at the same time added, and skills, but the result will be worth it.

The greatest subfloor heating will be carried out directly from the coolant outlet, because there it is hot. But as we move through the pipeline, it will be cool, that will cause, that the portion near the inlet for coolant postheating, will have a cool surface. To avoid this error have learned to arrange double snake, in which portion there is an alternation of hot and cold streams. mounting process has high complexity largely due to the fact, that have to create very large angle of the pipe bend. But here, craftsmen found out - creating loops on a bend. Work at the same time added, and skills, but the result will be worth it. - "Snail". It has high utility.

From the source tube is sent to the perimeter and rolled in a spiral toward the center, then returns back. This allows for the alternation of hot and cold streams, which leads to a uniform distribution of heat on the base floor. If necessary, a separate isolation area for better warmup, step pipe laying can be reduced to the desired size.

From the source tube is sent to the perimeter and rolled in a spiral toward the center, then returns back. This allows for the alternation of hot and cold streams, which leads to a uniform distribution of heat on the base floor. If necessary, a separate isolation area for better warmup, step pipe laying can be reduced to the desired size. - combined. It combines the above options in the same room. In addition, it can get a few snakes and snails in the room, creating separate circuits. All this is necessary in order, air was heated to a maximum, maintaining a minimum level of energy consumption.

necessarily Calculate power floor heating online calculator.

| feed temperature, OC. | |

| temperature back, OC. | |

| pipe step, m. | |

| Pipe | |

| Flooring | |

| The thickness of the screed over the pipe, cm. | |

| Specific heat capacity, W / m2 | |

| The temperature of the floor surface (medium), OC | |

| Specific coolant flow, (L / h)/m2 | |

Warning before laying pipes

Until that moment, how to distribute the tube in the base for heating room, should pay attention to some of the subtleties, allowing to create a truly efficient design.

For alignment a base pipe may be used self-leveling mixture, characterized by fast drying and create the best possible level surface. In the application of the plastic pipes most optimum section will be considered 20 mm. When the device "double snake" loop must be created a single tube. Otherwise there is a high probability of occurrence in the bending area.

Running warm water floor system can be carried out only after complete drying of the concrete pouring. Even after the start of feeding should be gradually pressure and temperature in the loop. Around the third day the system will be operational view.

Installing the collector

To place the collector in the room, pre-fixed collector wardrobe. When it's all done, the cabinet is started trumpet hot and cold water, which is connected to the relevant sections of the collector.  This equipment is based on the purchase order, a number of circuits will be used indoors.

This equipment is based on the purchase order, a number of circuits will be used indoors.

We can not exclude the likelihood of system repairs warm water floor. From this no one is safe. In this case, you should consider installing between the collector and the water pipe stopcock, allowing switch supplying coolant to the system.

In order not to bother about what is needed for the collector group, best find in the construction market ready version, where everything necessary for the full operation it will include. Each scheme of laying the floor of the water with the hands requires a separate connection to the collector. It is necessary to consider, and for what performed preliminary engineering system.

There may be cases heating system under the floor of the connection to the central heating. It does not have to install an additional pump for pumping. For stand-alone systems require not only the pump, but the drain pump.

Choosing boiler

Buying boiler must match with his power. Even at peak times it must have the ability to cope with any load during a water heating. But here, his work should be related to the maximum power, It must always be a certain margin. There is a certain formula, at which the power of the heating boiler is selected:

Moschn.kotla = Moschn.teplyh floors + 20%

In this case problems will arise with the operation of the entire system. The options have a large number of boilers. All of them can operate on gas fuel, by electricity or other. AT system pump is activated for full circulation water. If he chooses to work in one-, a two-story structure, then it will be enough (around the area 120-150 m2). Otherwise, you must purchase additional equipment. Right Online calculator to calculate the power boiler not be difficult.

At the inlet and outlet check valves in the boiler to be installed, necessary to turn off the system during repair work or preventive maintenance, when there is no need to produce the drain,.

the circulation pump is suitable for underfloor heating systems. They direct the heat transfer fluid at a specified rate through conduit. No overpressure is not created. But the pump in the boiler is best to choose three-speed, as it is necessary to change the velocity of the coolant depending on the time of year.

When purchasing a boiler should pay attention to its performance and head. First calculated by the formula:

Q = 0,86*Pн/(tpod.-Tobra.)

PH - power heating circuit.

The pressure is calculated:

n = (P * L + K)/(1000)

P - hydraulic resistance of each MP. tubes

L - length of the longest contour.

K - the power factor of safety.

That the heating medium is distributed evenly throughout the system water floor heating in the presence of several collector cabinets, the main route shall have a splitter. After narrowing it installed adapters. That this is the installation of water underfloor heating in screed.

Process screed

When you install all components of the floor heating and the final connection, should conduct a test event. This stage will identify possible errors, that could get out during operation. Then the consequences would be significantly. If any problems arise, you can fit in the fill underfloor heating system concrete solutions.

The process does not take much time with the right approach. Solution is mixed from components available, which also added to the plasticizer. The finished mixture is evenly distributed over the entire surface with a selected thickness. For this pre-better to arrange beacons on the basis of a profile, located on the mortar roller coaster, installation of water to warm floors in the concrete screed was carried out with correct thickness. May be used, and other special additives, specially designed for floor heating. It only improve the quality of the fill. In each specific situation to fill water floor heating technology should be respected.

Some experts can produce concrete floor When the operating system. In their words, drying process take less time. But better to experiment in such a case it is not necessary, because the surface may appear crack screed water underfloor. There have been carried out repair work, causing a waste of money and time.

When the screed is completely dry, which typically occurs within 4 weeks, You can proceed to the deck floor covering. No harm will even make a measurement of moisture level, which should correspond 2-4 interest.