For their own homes should be done all the best and modern. Especially when it comes to heating. Here it is best to approach the installation of warm water floor, which requires strict adherence technology. Demand for it is growing, but at the same time remain the same stages of laying the pipeline and all components. At the end of this process will only perform qualitative pouring from the prepared solution or choose grazing method, allowing to move away from the "wet" method.

Familiarization with underfloor heating

For underfloor heating characterized by certain nuances, without which knowledge can not get a positive result. If the technology is broken, then during operation will be impossible to achieve effective warming subfloors indoors. Besides, should pay attention to what, that such installation is feasible for residential buildings. In apartment buildings is unlikely to get special permission for the device. And the heating season will affect the degree of warm air in the room.

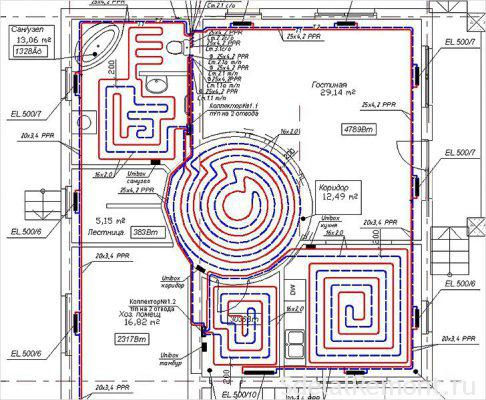

New laying system water underfloor heating in project. That there is no heating operation failures, instead of the central, Autonomous boiler works. Due to heat the room to carry out at any time and in its sole discretion, adjusting the temperature regimes.

The most popular at the device screed it has concrete, having a sufficient number of positive qualities, having at the same time easy installation. But if you pay attention to the other main options - grazing or semi-dry, then perform all the work will also be without too much difficulty. In addition, sometimes the results are even better, than when grouting.

There are a few basic and very important step, which produced installation of floor heating water type, selected step laying of floor heating.  All of them should be followed without fail and spend all the time necessary to achieve results. It is necessary to carry:

All of them should be followed without fail and spend all the time necessary to achieve results. It is necessary to carry:

- design and calculation of a warm floor.

- preliminaries.

- Assembling the collector group, pipeline.

- Screed floor heating.

- Flooring flooring.

Positive qualities and weaknesses

Underfloor heating can be compared with a radiator heating. And here once seen a lot of pluses, and that attracted artists to choose this particular design for heating the entire room.

- Reducing the heating process costs. For standard buildings energy spent about 25% less, and if the room will have a very high ceiling of more than three meters - is on 50-60 percent.

It is in the economy and is the main advantage warm water floors.

It is in the economy and is the main advantage warm water floors. - No component of underfloor heating will not create obstacles when planning and drawing room design. Radiator such quality can not boast. Constantly have to get heating elements and come up with ways to bring the room in the proper form.

- Uniform heating of the entire room from floor to ceiling and the base. Besides, With the right choice piping layouts, all floor areas will have the same temperature. This is especially true for children's rooms, when children are constantly on the floor games. The main thing to choose the right step of laying a water floor.

- About the heating elements can not be burned or receive any injury. All are securely hidden in the grounds of sex.

But in any technology can not do without the downsides, faced by performers during installation and the use of underfloor heating. Very complicated the process of laying the floor heating.  Here we need certain skills, which relate to the connection of all components to the collector group, and a conduit placing the base. So it is best left to professionals working in this area.

Here we need certain skills, which relate to the connection of all components to the collector group, and a conduit placing the base. So it is best left to professionals working in this area.

Failure to comply with the rules laying of floor heating or poorly selected components and material for underfloor, a high probability of leakage. Since this problem has to cope will be problematic for the reason, that will have to dismantle the flooring and screeds on a separate site. It is worth remembering, that the damaged portion can be a different distance of. Everything will depend on the length of the entire pipeline underfloor heating systems.

possible limitations

If the house is arranged an autonomous heating system, then such a system can be performed without problems. The effectiveness of its work will be noticeable from the first days. But residents of apartment buildings with central heating think about, as put a warm floor. must, everything to be incorporated into the project. Otherwise, you must obtain a permit, which hardly anyone will. It's all focused for a change in pressure in the core networks. In addition, there is a risk for tenants, as well as for utilities.

If desired, yet to arrange a warm water floor in a residential apartment building, It must be equipped with a heat exchanger. After that there is an agreement with the operating organization.

Particular attention should be paid to the choice of flooring. Can be used even linoleum. But if it is a low grade, the high probability of selection of foreign smell. The most optimum variant - tiles or laminate.

When choosing a heating system it is important to monitor the temperature of the water in the circuit should not exceed 50 degrees. To put this temperature automatic three-way valves.

It is not recommended to use as a floor coating or carpet parquet. This is all due to their high thermal insulation capability. They also have low heat output. Efficacy in this case by the system warm water floor markedly reduced.

Selection method and circuit

Two basic methods can be selected for the device "pie" underfloor:

- Concrete. The easiest and most common option. heating surface is placed under the concrete floor. Works will have to produce a lot of. Sometimes even on their own to perform the installation will be problematic.

There will need to choose the optimal thickness of the layer, that the quality was the best floor heating. Before the flooring floor covering also need to wait until all time dry solution.

There will need to choose the optimal thickness of the layer, that the quality was the best floor heating. Before the flooring floor covering also need to wait until all time dry solution. - Grazing. Concrete works here does not take place, and there is no "wet" method. During execution is not applicable at all water. Main components - ready materials. This makes it possible to reduce the number of waste on the installation of floor heating, as well as during the meeting. But it is worth noting, the more layer "cake" will, the more money will be spent. Depending on the material selected and isolated in several species of: polystyrene system, and wooden (rack or modular).

In each case, you should know, as lay floor heating. All the subtleties enclosed in technology, to be followed.

The optimal distance for laying of floor heating pipes of 150mm.

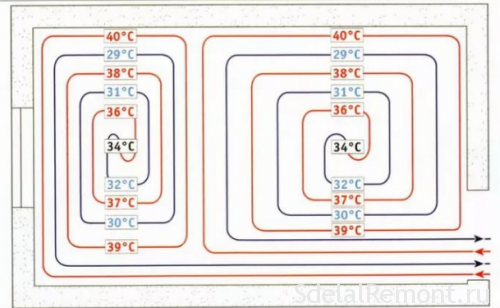

Particular attention should be paid to the selection of the scheme laying pipeline underfloor heating. There may be a few basic options: snake or snail. The most effective method is "snail", when the pipes are arranged in the entire area of the room in a circle, from the walls and toward the central part. After reaching the conduit is directed back center. Efficiency is, the hot coolant will be distributed over the entire surface in the room. It will be located, alternating with reverse flow, be cold. It is very important to choose the step of laying the floor heating pipe, which will allow to transfer heat across the floor surface.

With regard to the scheme "snake", the less its uses as a core and single variant. The fact, that the main heat will concentrate on the hot coolant exit portion. Second half, which will be directed to the withdrawal of the cold stream, It will warm much less. Alternatives and more effective - the double snake. But the installation process takes more time and requires attention. There are features and the correct distance laying of floor heating, from which the degree of heat transfer will depend, as well as uniform distribution.

There is also a combined scheme, when both of the above embodiment are combined with each other. So, eg, you can arrange a scheme "snake" at the entrance to the room, and in its central part, where to spend most of the time - choose a scheme "snail".

Design

Preliminary all should think wisely. From the options presented, select a particular, whereupon schematically all displayed on paper to scale, relative area of the room. After spending pipeline on paper, you can calculate the necessary amount of it in reality.

Particular attention should be paid to the collector group and the selection of the boiler. Power the last should be enough for the entire circuit. At the same time it should not work for wear. Should remain power reserve. among the nuances, which draws attention:

- Parameters of the entire premises, its configuration and area.

- The temperature in the room, which will be necessary in the operation of floor heating systems.

- Features pipeline, its diameter, as well as all other components. When to arrange a warm floor, stacking step tubes points to the need for its amount.

As for the tubes, it is necessary to calculate it beforehand online calculator water heating, that during the whole device for a floor construction has been no deviations. It is best to pay attention to the entire system for underfloor heating, where are all the necessary components.

preliminaries

Any introduced error, even the smallest, It can lead to serious consequences. For this reason, you should strictly follow the technology and installation instructions. All of the ground under the floor heating should be aligned roughing screed. Otherwise, the water will begin to deform the floor contour, which will lead to "airing" of the system. In the presence of cracks or other defects, they must be removed and sealed solution.

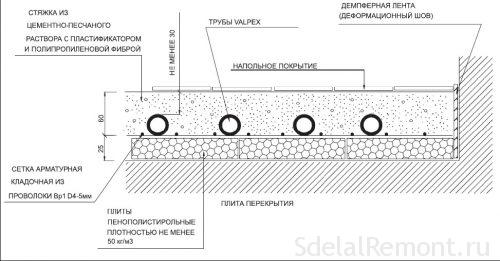

Originally produced styling insulation, so that the heat store and transmit it inside the room, rather than spent on downstream heating floors. The most optimal material for this - penoplex or polystyrene. If the material is no special hardware for pipes (boss), the further layer is arranged reinforcement metal mesh.

Fastened to the damper tape around the perimeter of the room, to tie was in good form during the operation and heating underfloor space. As usual waterproofing material is chosen from polyethylene film.

To the reliability of the whole structure was high, reinforcement layer and laid on top of the pipe.

The main units

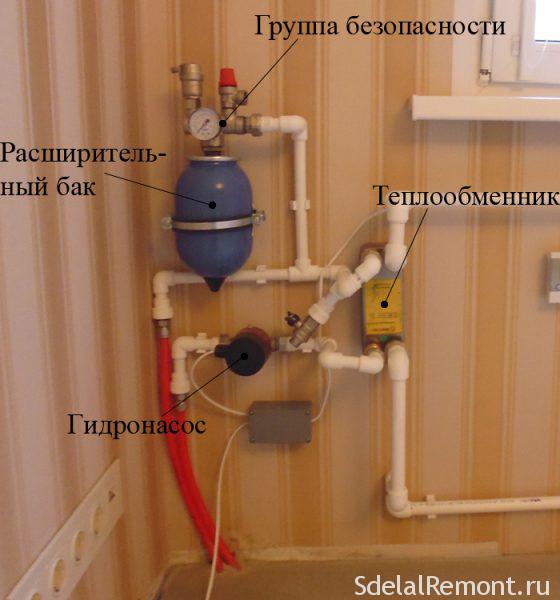

The existing pipes must be necessarily connected to the collector group. Most often this involves the installation of a collector box, which is mounted on the wall.  For uninterrupted circulation of the coolant meets the mixer in the pipe system. Collectors can distribute flows of hot and cold media.

For uninterrupted circulation of the coolant meets the mixer in the pipe system. Collectors can distribute flows of hot and cold media.

The boiler is selected according to the required power. Of no little importance here to play, and the financial component of the issue. After all, you can buy boilers with automatic configuration of coolant flow, temperature selector and the other parameters. In fact, it will be enough once properly set up the system, selecting the appropriate step of laying water underfloor heating and later use it for pleasure. Right calculate the power boiler will help online calculator.

Excellent work of boilers provides a circulation pump. Overpressure is formed, and a coolant is guided into the pipeline. The most optimal variant of the pump - Three-speed, allowing to change the coolant velocity in the system, depending on the time of year.

Particular attention during the purchase of addresses on its performance and the pressure. Performance is calculated by the formula:

Q=0,86*Pн/(tpod.-Tobra.)

PH - power heating circuit.

The pressure is calculated:

n =(P * L + K)/(1000)

P - hydraulic resistance of each MP. tubes

L - length of the longest contour.

K - the power factor of safety.

pressure test

When completed all the main types of works on the device, Set step of laying pipes of water underfloor heating,  should be carried out on the performance of activities for the system check and detect possible defects. To do this, run hydraulic tests. This system is not only the checked for leaks, but also strength.

should be carried out on the performance of activities for the system check and detect possible defects. To do this, run hydraulic tests. This system is not only the checked for leaks, but also strength.

Initially fed water or another coolant under pressure selected, which is about half a large, than normal working. Perhaps the pressure oscillation in the system. Tolerance is 0.02 Mpa. In any case, the coolant temperature should remain unchanged.

standard pressure, in which the system pressure test carried out - 3-4 have. Works are carried out for at least days, to make sure there are no problems. The best tool for the job - a hydraulic press or an air compressor.

If they found any errors and problems pipeline, other components of the floor heating, will have to make repairs. In any case, continue on installation activities can not be.

screed

In most cases, to cover the entire heating surface is used concrete floor. It is widely used, but ordinary concrete approach can not.  If you use sand concrete is to be not less than the M300, to get high quality. Be sure to add plasticizer and other optional additives, allowing to efficiently produce fill.

If you use sand concrete is to be not less than the M300, to get high quality. Be sure to add plasticizer and other optional additives, allowing to efficiently produce fill.

Screed must be selected optimal thickness, which will allow the system to warm up the room in the required quantity and with proper use of energy resources. We can not allow a very thick screed, which will exceed 10 cm. It will require a lot of money for a "cake" of the device, and a large number of investments and payment for heating efficiency is low.

When all produced in series, observing technology, We get a really high-quality design of the whole "pie". The floor in the room will be qualitatively warm up throughout the area. Comfort and convenience will not leave the premises, where the system is arranged.