Apparatus warm floor water type requires the most advanced technology and materials for solution preparation. Great importance is given to each stage, which also includes the screed. In this case, you should consider not only the quality of construction, but also the choice of an optimal thickness fill layer.

notion

performance level screed assembly over water underfloor heating will subsequently have an impact on the efficiency of the whole room heating system. If everything is achieved according to the technology, and the warm floor can serve for a long time.  If you violate the level filling, screed very quickly will become worthless, damaging the flooring selected.

If you violate the level filling, screed very quickly will become worthless, damaging the flooring selected.

Some think that, that you can not spend a lot of money, and produce fill thin layer above the pipeline underfloor. But in this case, most likely the rapid appearance of cracks on the surface. No significant loads can not stand base. Even the rearrangement of furniture within the room can harm arranged screed.

But a thick layer would not achieve the desired result. a large amount of money will be spent on the acquisition of the components of the solution, tubes on the screed, and the effectiveness of a warm floor will not be able to prove. admitted errors have eliminated. The fact, that in such a case would have to spend a lot of resources for heating just fill layer. It will be necessary to wait a long time to warm up the subfloor, to the room to feel comfortable.

At optimal indicator layer pouring water underfloor heating It affects not only the configuration of the entire premises, its area and dimensions of the walls along the length, but also the basis of gender or the type of soil, wherein floor heating device produced.  In addition, it is worth noting, that each room has its purpose, of which will depend on the final casting thickness. For premises it will be somewhat less, than at floor equipment room for industrial use.

In addition, it is worth noting, that each room has its purpose, of which will depend on the final casting thickness. For premises it will be somewhat less, than at floor equipment room for industrial use.

Among nuances can note the presence or absence of the reinforcing layer, addition of the various components in the form of fiberglass or plasticizers. In each situation to the choice of the thickness of screed water underfloor heating should be approached weighed individually.

Types of filling level

There are minimum and maximum height of the underfloor heating screed in the room. All of them will have its own peculiarities and subtleties in the conduct of assembly. By types are the following embodiments screed:

- Thin filling. Here it is best to apply the self-leveling mixture, allowing the screed to create a layer 20 mm.

In any case, the distance from the pipeline must vymeryat level. As a result, the surface will be sufficient to withstand the load, including by straddling the bulky furniture. The composition of such a mixture, that does not require reinforcement layer. Fortress and tie the reliability of an item.

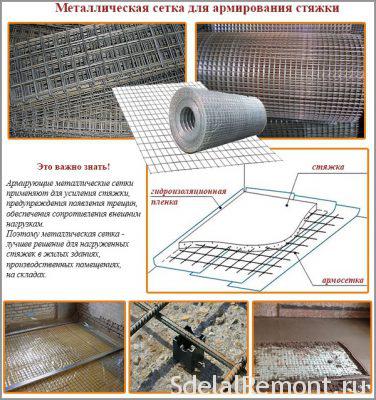

In any case, the distance from the pipeline must vymeryat level. As a result, the surface will be sufficient to withstand the load, including by straddling the bulky furniture. The composition of such a mixture, that does not require reinforcement layer. Fortress and tie the reliability of an item. - Srednesloynaya. This refers to the optimal fill layer, when filling produced approximately to the height 50-70 mm from the top of the pipe loop. In addition, a metal mesh is used to create a solid structure, a part of the total thickness.

- thick-layer.

No specialist will not recommend to perform fill a height of 15 cm. And these figures are among the latest, above which has no effective layer will not be. Besides, what will it be strainer, as such, often in the private construction of such a layer performs the role of the future structure of the basement.

No specialist will not recommend to perform fill a height of 15 cm. And these figures are among the latest, above which has no effective layer will not be. Besides, what will it be strainer, as such, often in the private construction of such a layer performs the role of the future structure of the basement.

It is worth noting, Much will depend on the composition of floor heating solution, all components. there is a minimum threshold for adding gravel to 50-70 mm above the level of the pipeline. But plasticizers Conversely can reduce the fill layer to 30 mm.

casting components

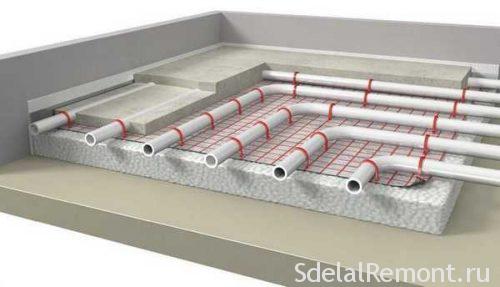

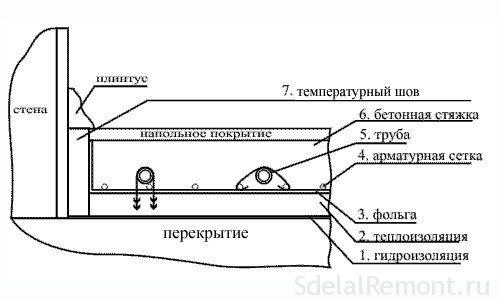

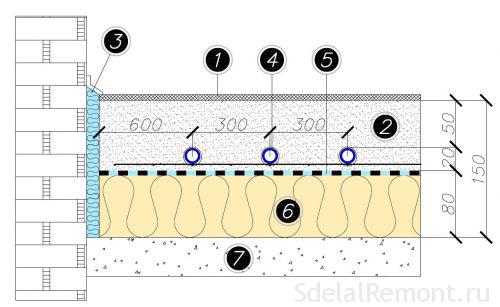

except for the screed floor heating we can not forget about the other components, included in the total thickness of the "pie". After alignment blister base screed, should be carried laying insulation layer. There may be quite a different material. It is worth noting, that insulation mats can have grooves, which will be placed in the conduit. This significantly reduces the time to perform the installation, so how to choose a step for laying will be much easier. Thickness insulation It can vary from 50 to 100 mm, depending on weather conditions and the location of the premises in relation to the number of floors and basements.

If the mats are to warm the standard, smooth on both sides, it is best to arrange a reinforcement layer of metal mesh, to which will be produced by fixing the pipe. by the way, line also affects the thickness of the "pie" underfloor.  Typically, its diameter is up 2.5 cm. But some prefer and other non-standard options, which can increase or decrease these rates.

Typically, its diameter is up 2.5 cm. But some prefer and other non-standard options, which can increase or decrease these rates.

The final floor - screed flooring and decking. About tie layer can be a lot to say. the main thing, The thickness was optimum size, which will completely warm up the subfloor and keep warm a certain time. The thickness of the floor covering is included and a minor layer of the fastening element. If you touch the tile, we are talking about the glue, level that can even make minor alignment defects of the surface.

Composition of solution

Purpose room, where held installation of floor heating will influence the casting components. For residential premises is enough cement brand M200, is added to a solution of, but industrial projects - not lower than M400. All the matter in the final strength of the structure.

Do not be amiss in the composition will add a variety of supplements as plasticizers, that allow to perform a lower layer of screed, and will not contribute to the formation of cracks and other defects on the surface.

Old folk remedies suggest the possibility to replace the plasticizers other materials - PVA glue. true, he was not justified due to the emergence of more modern technologies, allowing to obtain the best results most.

minimum

For minimum thickness screed water underfloor heating has established building codes. There is clearly spelled out, from what to make a start during the filling of the contour of the solution. typical thickness for leveling mixes in 20 mm.

Standard execution of screed 40-60 mm. Much will depend on the availability of all layers, which are part of the overall pie. Layer reinforcement on top of the pipeline is not always applied, it is not always in that there is a need. Without it, a very thin layer can not always be robust and reliable.

On minimal rates thickness can be thought of only in the case, when it performed qualitatively rough base on the level. Even minor imperfections and differences in elevation in the end can affect the degree of fill. This indicates, that every step must be to think for the future, when any error will affect the reduction of the distance from the ceiling to the floor. Especially it is important for rooms with low ceiling level.

Instead of metal mesh are now accustomed to use alternative means - fibrovolokno, having the same characteristics, besides creating the possibility for uniform distribution of the surface of the solution due to the plasticity.

If done efficiently and with optimum performance in all the thickness of the "pie" warm floor, there will be no extra costs for heating. The floor is always warmed up to the desired level. Some manufacturers recommend to arrange for a certain layer thickness, depending on the composition of the solution. This they prescribed in their recommendations, and which should be followed.

Limit layers

There is a maximum height of the screed Radiant floor, above which is no longer any need and usefulness. It will spend a lot of time to fill, but suffer to a great extent the efficiency of underfloor heating systems. After all the resulting "cake" will warm up continuously.

Maximum thickness can reach 150 mm. Much will then depend on the destination premises, where the works. Moreover, in this case mainly made of monolithic construction apparatus. The height of the screed for underfloor heating water and also serves as the foundation. Large thickness should be provided for certain types of premises, such as garage, parking areas, etc..

It comes up to the maximum fill thickness in the situation, when the soil at the base of a very bad. After a warm water floor mounted usually in private buildings. Otherwise, the destruction of the whole structure. Money is spent will be a lot, but no results will not be. Only high-quality materials should be used in the process of preparation of the solution, because the whole structure is created for a long time. It is better to spend money once, than to spend money on carrying out time-consuming repairs.

To reduce some costs in this case, it is best to bring down the maximum projections based on, additionally arrange for the filling alignment. But this should be done before the device of warm water floor. Subsequently, it will be much easier to carry out all stages of the installation of water floor heating.

If the contour pipeline It will be located in a thick screed, may have operational problems, associated with prolonged heating subfloor. It will spend a lot of resources. The benefits of the system will not have any. This indicates, that it is necessary to arrange a competent pre-draft floor, to produce pipe installation without affecting their integrity.

manufacturers recommend

Each manufacturer puts certain parameters height of floor heating. This comes from the used pre-mixes, which are slightly different from each other by structure. Screed over underfloor heating water must be evenly distributed over the surface and at the same time to wait until dry. It is from thickness and will depend on the active period until the flooring planks.

Company «Kan» for its clients in the recommendations prescribed, that over tubes underfloor heating must be screed with a height of about 45 mm. If the total number of take another and the pipeline itself, then screed thickness should be approximately 65 mm. I.e, height will come from the top edge of the circuit system of warm water floor. In addition to selecting a specific mixture of plasticizer, the prepared solution can be poured onto the warm surface of the floor to a height of just 25 mm. I.e, one additive significantly reduces the costs of the screed installation.

In «Rehau» company a slightly different approach to the optimal performance level filling. The whole structure, the height of the screed over underfloor heating should be at 61 mm from the base, together with the conduit. But also in the work they use several smaller diameter pipe. The most important thing, that it was sufficient for the direction of flow, and the transfer of the required amount of heat floor. For industrial buildings a few different thickness. It averages fluctuate within 75-92 mm.