Underfloor heating can not do without quality drenched concrete screed, which in operation performs a lot of functions. But this should be familiar with the general structure of warm water floor, and learn about, What are the minimum performance screed thickness over underfloor heating must be, that it meets all the requirements and technologies.

designation

The thickness of the screed underfloor heating will affect the performance of the entire system, as well as its ability to work effectively, provided on the outer side loads. It should be understood, that the layer must be optimal for the manufacturer and comply with the recommendations, if applicable finished construction dry mix.

If on the basis of gender will be arranged very thin pouring of concrete, the last for a long time she could not. In addition, there is a very rapid heating of the surface and the rapid cooling process. Any good she can not bring. With this in mind,, especially if the room load has constantly not only on the movement, but also the location of furniture, the minimum strainer under floor heating very rapidly crack and lose its appearance. It all will also damage the floor covering, which will lay on top.

A thick layer of concrete casting solution is also not able to show all the features of warm water floor system. Warming of this design will be very difficult and problematic. Chances general failure pipeline in some areas.  All of this will cause a large financial investment in the heating payment. After all require large amounts of energy, to heat passed through a thick layer of screed, warmed the subfloor in the room.

All of this will cause a large financial investment in the heating payment. After all require large amounts of energy, to heat passed through a thick layer of screed, warmed the subfloor in the room.

It is impossible to talk about, that there are universal values for the device concrete screed over underfloor heating system. The fact, it is worth taking into account some factors, such as the type of base, configuration and area of the room, where the works, as well as his appointment. After the load in residential areas will be considerably less, than industrial. Consequently, in the latter case fill layer to be somewhat larger.

Unlike conventional screeds

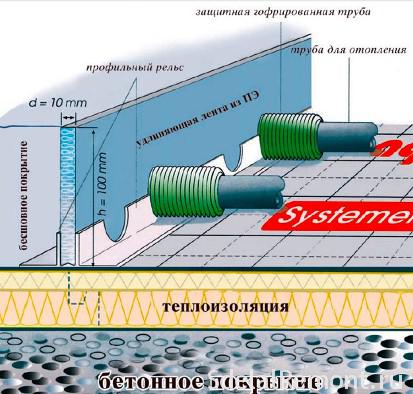

Plain tie is somewhat different from the ties of warm water floor. The fact, in the latter it should be a mandatory order expansion joints be arranged. Even in areas with a small area to 10 m2 they must be present. In addition, should get the band amortization, which is laid along the bottom of the wall. That's all you need to compensate for thermal expansion concrete screed while the warm water floor system.

For large floor space of seams executed even further. Here, the compensation function is performed in addition to tape and insulation for walls. In this case, thermal insulation must be termoottalkivayuschuyu foil.

Number of screeds for underfloor heating

At first glance, a very strange question about, how many ties should be designed for the system underfloor heating. Besides rough screed, performed for optimal screed over the floor heating pipe. The last layer will form the basis for the final floor finishes in the room. Alternative roughing screed - floor slab. But in this case it must be almost perfectly flat and free of defects. Otherwise it is necessary to arrange the alignment layer.

Warm water floor necessarily mounted on the base without errors. It should be smooth. This is necessary in order, to the subsequent pipeline it was evenly distributed in the concrete screed for finishing.

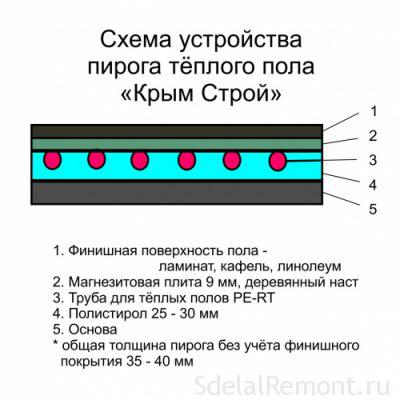

Components of underfloor heating

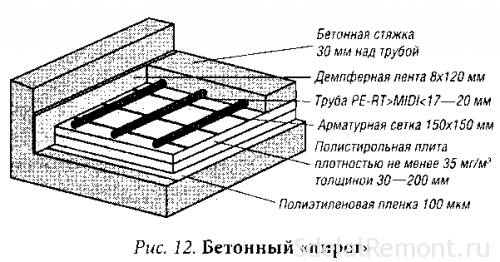

The whole system of floor heating together with a coupler having a certain thickness, which must have optimal parameters. In this case it is necessary first to determine the order, what is generally included in the base floor heating system and a thickness of each layer may be.

- initially, the level ground layer arranged heat and waterproofing. Polystyrene insulation often selected due qualities and characteristics exhibited during operation. Typically, the thickness of floor heating are taken within 80-100 mm. It is this layer will be sufficient, to keep warm, and send it in the right direction. Even if it is located at the bottom of the basement without heating. The overall thickness of the floor heating will not affect waterproofing, since it is performed from a very thin plastic film.

- Insulation can be purchased with special recesses for the pipeline facilities. In its absence is possible to arrange a layer of reinforcing mesh or acquire MAC, to which it is very easy to produce a mounting pipe. For metal mesh reinforcement thickness is approximately the same with the grid and is approximately 4-6 mm.

- the pipe itself, which is used for floor heating system water. The diameter may be quite different. But it is recommended to take no more 20-22 mm diameter. It will be sufficient, system to operate fully.

- Screed over the warm under-floor finishing coating. Here, there are subtleties solution preparation and selection of suitable material (Cement, sand, supplements, plasticizer and TD). AT Finishing coating is added and the layer for attaching (glue), that refers to a ceramic tile.

The composition of the fill

To get started is to decide on the brand of cement for mortar. It should be M200-M300, depending on the destination of the premises. In addition, the composition may be included in the plasticizers to avoid the appearance of cracks on the surface after pouring, as well as a better distribution of the base. When arranged under floor heating screed thickness shall comply with all the requirements and recommendations.  Usually it is 50-70 mm. Start filling level goes from the top of the pipe system. Optimal parameters can advise manufacturers and dry mixes for the preparation of concrete mortar. It should also be followed in the implementation of installation.

Usually it is 50-70 mm. Start filling level goes from the top of the pipe system. Optimal parameters can advise manufacturers and dry mixes for the preparation of concrete mortar. It should also be followed in the implementation of installation.

Instead plasticizers can be applied, and "popular" means a PVA glue. Such methods have been applied years 15-20 ago, when technology was not as well developed. It is worth noting, that the cost of the various additives now not so much, and you can afford to buy them. Moreover, their consumption is not high on the volume of concrete solution. In this case, the thickness of the screed floor heating pipes can be even more reduced, by improving the strength characteristics.

minimum parameters

Building codes provide the minimum limits for the performance of pouring concrete screed. This is spelled out in the relevant documents. But not everyone knows about, which screed thickness for a warm floor water can be.

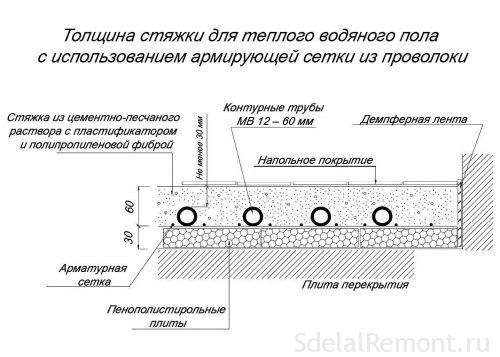

minimal screed thickness underfloor heating must be 20 mm, if used in self-leveling mix without reinforcement layer. If this is a classic concrete screed, it is no less 40-60 mm with the reinforcing fiber arranged. true, not always metal grid laid over the pipes. This is done in the case, if there is a desire to strengthen the entire structure and to create a reliable protection for the pipeline.

Minimum screed water underfloor heating It can be considered for execution at the rough layer arranged, when the base is aligned with and tailored to the horizontal level. laying pipeline in any case must be performed on a flat surface without errors and defects. About the minimum thickness of the screed over underfloor heating can talk, if you completely forget about the reinforcement. This layer should be skipped, to not suffered the distance from floor to ceiling. Currently, there are alternatives to the metal mesh - fibrovolokno. Addition of its small size the prepared concrete mortar, It will provide the same performance without an increase in the fill layer.

Minimum layer screeds for floor heating does not fit with the manifestation loads during operation. It can be installed bulky furniture, household appliances, etc.. All this may damage the surface and cause useless roofed floor. So what you should know about, What thickness of ties underfloor heating is optimal, and under what conditions it will be used.

Typically, underfloor heating screed layer will be sufficient to 60-70 mm arranged with a floor covering of any kind. It will be shown all the quality and efficiency in the work. The floor will be warm in the required quantities at minimal costs for heating.

Limits screed pouring

The thickness of the screed over water underfloor heating can be up to a certain height parameter, It fulfills its function. Documented not spelled out anything about it. No one advises to choose the thickness of the screed for underfloor heating under the tiles are not more 15-17 cm. Otherwise, you will just waste of money for the purchase of material, and the time for performance of work.

The minimum thickness of the screed for water underfloor heating can not be provided, When you create a solid structure. That is screed over underfloor heating pipes performs the role of the foundation of the house. The situation is similar in the areas of specialized, that no longer have a commercial value (garage, warehouses, parking).

As the water heated floors in the main are held in private buildings, then it is here that there is another problem - the problem soils at the base. If any can not be considered such parameters, the minimum thickness of the screed above a water underfloor. The fact, that in the case of a minor filling level, over time it can break and have an impact on all components of the design, including piping with flooring. The system is mounted on the year, Consequently, care must be taken, to create the necessary tie layer over underfloor heating.

With significant surface roughnesses, large differences in elevation, should think about alignment it necessary to limit. All projections astray, and the other parts dry material backfilled. Such manipulations are carried out prior to the installation of underfloor heating.

Using the filling layer allows to reduce costs for the preparation of the solution of the concrete screed.  After the fill level of each centimeter requires a certain number of concrete solution. The larger this index, the higher costs. One cubic meter concrete to fill the space in the room 10 m2 and screeds for floor heating thicknesses just 10 cm.

After the fill level of each centimeter requires a certain number of concrete solution. The larger this index, the higher costs. One cubic meter concrete to fill the space in the room 10 m2 and screeds for floor heating thicknesses just 10 cm.

If you do not get the minimum screed floor heating, and reached the maximum limits, it is necessary to bear in mind the difficulties and problems, that will be faced during the operation of the system. The floor surface in the room will be heated very long period. All this will be spent funds, to "to heat" the whole "pie". Consequently, the efficiency of floor heating will be reduced to a minimum or nothing at all will. So that, when a screed floor heating optimal thickness should be adjusted as possible.

Recommendations from experts

Everyone wants to get an answer to that, what screed thickness of water underfloor heating is the most suitable. The unequivocal answer here in any case not be able to get. For this study the subfloor, all the requirements for filling, and operational characteristics. There are tips from experienced craftsmen, that claim, that the following conditions would achieve the maximum effect from the arranged underfloor heating system.

- The minimum thickness of the screed pipe underfloor heating must be 50 mm.

- Placed in a screed floor communications should be placed in a protective corrugation. The minimum thickness of the screed floor heating under, passing over the flexi hose must be 20 mm.

- For certain premises (corridor, bathroom, kitchen) the minimum thickness of the fill layer without underfloor reinforcement – 70 mm.

If it is possible to increase strength of the solution using various additives, the level can be reduced to 40-50 mm. Here, the device helps reinforcing layer, strengthens the entire structure.

If it is possible to increase strength of the solution using various additives, the level can be reduced to 40-50 mm. Here, the device helps reinforcing layer, strengthens the entire structure. - For children's rooms screed thickness over the warm floor is taken within 50-60 mm. Additionally, the overall "pie" added sound insulating layer.

- All accommodations have possibly have the same thickness on a warm floor screed and tiles. The low level is provided only for the bathroom, to eliminate the possibility of water at the strait pipeline accident.

- When choosing the optimum thickness of the screed floor heating water should focus on doorways. When the device require a thick layer of individual order door panels. This in turn leads to higher costs.

Decide with all screed for underfloor heating rates allow competent attitude and recourse to experts. Given their experience, they can suggest the right choice in a particular situation. At independent performance, no harm will be possible to view the video, and follow the recommendations of material manufacturers, used for.