Underfloor heating is not considered a surprise in today's world, and properly. He proved to be excellent and displaces conventional radiator battery market. There are many technologies, which can be arranged in a warm water floor. This led to, many wanted to know about, how to make a warm floor without ties.

Benefits

Warm floor without screed has many advantages, compared with other technologies, among which are the:

- It is possible to arrange matter, what basis there.

- Virtually no loss in the distance from floor to ceiling in the device of the whole structure.

- Reduced to a considerable extent roof load due to the low weight of the "pie". This allows you to install radiant floor heating without a tie, even in old buildings with wooden base.

- No drying wait time concrete screed after pouring. By finishing floor covering can begin immediately after, configured as a warm water without screed. It is possible to arrange the heating system on wooden base, on the concrete floor, as well as on logs.

Consequently, there are no special preparations for the behavior mounting this design for high-quality heating in all rooms. The works can be carried out even beginners. The main requirement is to fully comply with the technology and to start performance only after reading the basic intricacies of.

types of structures

Installation of water underfloor heating without ties can be started, If the foundation is prepared for him. In its capacity as may be:

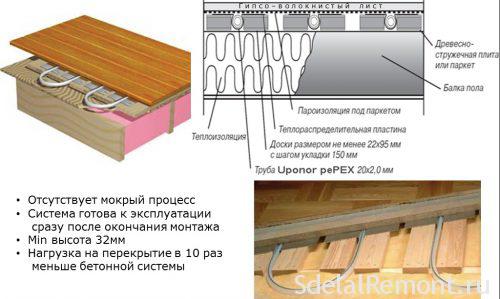

- Tree. Special modules, in which there are special tubular channels. channel size should completely coincide with the selected step of laying floor warm water conduit. Most often, modules for underfloor heating without a tie made of OSB or particle board.

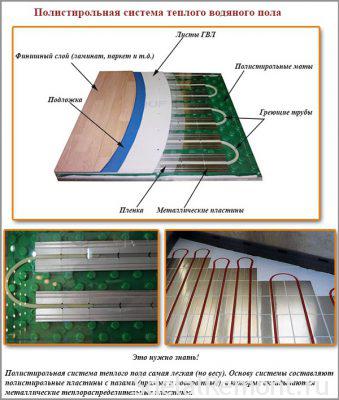

- polystyrene. Represented as a standard size plates 1.5*0.5 m. They have a special attachment, intended for fixing the pipes with high quality increments selected. Themselves between plate is attached with the tool joint.

Attention should be paid and pipes, which will be used in the constructions of the above. But the most popular plastic or metalloprofilnyh, copper pipes and stainless steel pipes can be acquired, having a higher value. Easier and more convenient to work with pipes of crosslinked polyethylene, having excellent performance. Among their advantages distinguish the ability to withstand aggressive media. Using this material, life time underfloor heating It can reach up to several tens of years. the main thing, here to fully comply with mounting technology, as well as the operating conditions.

Most often purchased coiled tubing. Thus it is necessary to pay attention, it is better not to stretch the loop, as it may occur in a separate room pipe portion. It is best to gradually unwinding it in the process of laying on the base.

Materials used

Laying underfloor heating screeds without the use of the work involves not only the pipeline itself and all the components as a basis (polystyrene, tree), and the top coated tubes. This may be in the form of moisture proof material pads and floor, used for decoration (tile, carpeting, laminate, etc.).

The heat exchange medium may be not only water, but also any type of antifreeze. Any negative impact on thin radiant floor heating without a tie, they will not be able to provide.

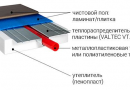

Stove styrofoam is, including thermal insulation, to heat does not leave a rough base and downstream floors, and completely transferred into the room. The width of the wooden plate units can be 13, 18 or 28 cm. all will depend on, what kind of a step of laying a pipeline is chosen in a particular situation.

By yourself tubes flooring produced heat distribution plates. Most often they are made of aluminum or galvanized steel. They have a special slot in the middle, where pipes are laid themselves, as well as the ribs. When you buy should be paid to the groove diameter, since it will depend on the material of the warm water loop sex.

Laying water loop

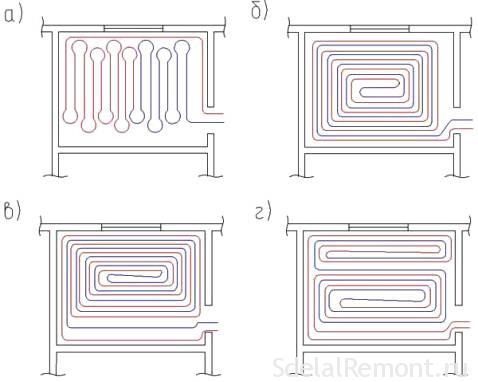

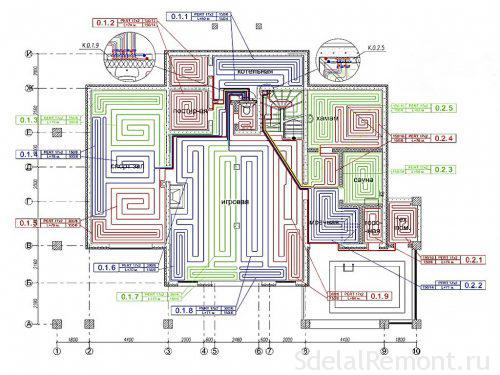

Before, how to make installation of water warm floor without ties, should think about the arrangement, pipeline system. For this pre-plotted a plan on a piece of paper, which is subsequently transferred to a real base. Among all isolated circuits "snake" or "snail". Furthermore it can be combined method, when the two circuits are combined in one room for a better warm-up and the efficiency of the underfloor heating water type.

The most popular and the best of the characteristics of a "snail". In this case, the heat is evenly distributed over the entire surface by alternating the hot coolant inlet pipe and the outgoing cool. If necessary and the presence of the edge zones in the room (exterior walls), pipe-laying step is reduced for better heat distribution.

scheme "Snake" is better suited for small spaces on the square. If necessary the device of warm water floor screed without even the average area of a room with 10 m2, Such a scheme can be applied, but will settle its kind - a double "snake". In a typical design and coolant, Consequently, subfloor will warm up at the beginning of loop warm water floor and is cool to the exit. This type of stacking water circuit is best applied in conjunction with the "snail".

Depending on the destination premises and project requirements, selected stacking step. It will also differ depending on the basics, which produced styling. Most desynchronization step is provided for a scheme "snail", where it can be from 10 to 300 mm.

The basis of polystyrene

Installation of floor heating without ties can be carried out on the basis of polystyrene. To say in simple language, it is an ordinary foam, having a sound and heat insulation. During operation, it is not subject to rot and can last a long period of time.

At the beginning of the work should be explored technology, how to make Radiant floor without ties on the basis of polystyrene. Here everything is done consistently and gradually:

- Basic thickness selected for polystyrene 30 mm. That such sheets and the foundation is laid for a warm water floor. In some situations, it may require more insulation. Then it is necessary to create an additional layer of polystyrene plates.

- When laying plates directly with the rough base, the latter should be carefully prepared. To this end, it carried out any kind of alignment screed, then all debris is removed, even dust. We can not allow irregularities under the decking boards, as well as the mobility base.

- For polystyrene plates characteristic of step 15 and 30 cm. They are on top of the grooves (boss), and where the pipeline splits. To interconnected plates are securely fastened, uses special snap locks. It is worth noting, that the slots on the plates can be not only straight, but turning, and what you should pay particular attention. Everywhere is to adhere to a pre-decorated layout plan.

- If necessary, on the surface of polystyrene boards is a special marking for better layout pipeline. This is most characteristic of the universal boards with bosses.

- Pre-made aluminum plates laying in the slots, and after the tube and the plan.

- At the end of the whole construction of the pipeline system of warm water carried floor laying pads for protection against moisture, and the selected option floor covering. It is worth noting, that depending on the coating should choose the best option Ties: ceramic tile best suited dry screed as chipboard, water-resistant plywood or drywall.

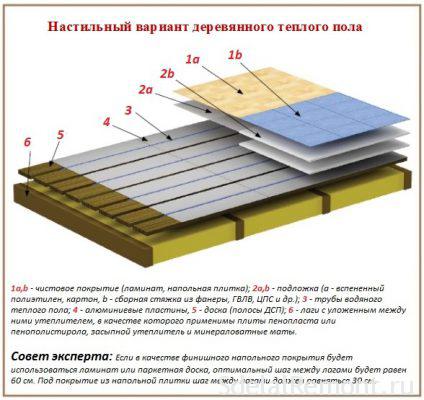

Wooden flooring options

Another option, on which can be arranged Radiant Floor without ties - wood flooring. He often arranged in wooden buildings. special module can be selected based on its, or rack and pinions carried on laying the foundation. Both of these options are identical in principle. The difference is, that is used for mounting. Modular system - ready modules in a wood stove, with integrated grooves for laying pipes quality. For rack - boards or slats.

Wooden plank warm floor without ties It should be performed in the following sequence, which requires the technology:

- Stacking modules are on the joists with a pitch in 60 cm. Between joists arranged distributed waterproofing together with a heater. That is, space is created to improve the quality of the heating of the entire system. The gaps between the modules - 20 mm. This creates the space necessary for the, to compensate for thermal expansion of the material during operation. Classical clutch modules - using special locks, that simply snap each other.

- When reechnyh type of flooring should be made sub-floor. The distance between the strips should be such, to put them on tubes system. All will depend on the scheme for circuit.

- Must be respected layout plan, regardless of, which option is selected styling - the module or rack.

- On the system of modules produced stacking metal plates, in which are placed the pipe itself.

- If the topcoat is a solid and has thickness more 10 mm, then it can be laid directly on the resulting structure with the substrate laid to improve sound insulation qualities. Under such floorings, linoleum or tile, a specially prepared wood coating.

Radiant without screed allows you to create an excellent heating system in the room, as well as improve the quality of sound insulation.

Features of laying a tile

Laying underfloor without ties tile It has its own characteristics, you want to know when the independent performance. The material for the floor plank is popular in these areas, as the bathroom, kitchen or hallway. All proceeds from its practicality, High Quality, long period of operation. In addition, take care of each tile can.

The nuances are that, which follows on polystyrene plate further lay coating, protects from moisture. This can be used as sheets GOLS. Then you can start laying the tiles. Even in this case the ground under the polystyrene boards - exclusively smooth. Otherwise, you may be faced with the, that the warm water without floor screeds under tiles will reduce the heat transfer due to the deformation.

floor heating device under the laminate

Run water floor under the laminate without a tie and everyone can, who chose this floor for finishing. All the technology is, that occurs fastening material using special clips and fastening tapes.

Until that moment, how to perform a radiant floor heating without a tie under the laminate, It should produce some very important actions:

- Identify places a heavy arrangement of furniture in the room. Placed underneath the floor heating circuit is not rational. No, he will not bring efficiency. It is worth paying attention to, that in the presence of radiators in the room, about them, or rather beneath them, also it makes no sense to make the location of the pipeline. Prohibited produce flooring of different carpet or carpet on top of the pipeline system.

- Laminate should ventilate. It should think about the pre-and do not forget about the item. With his installation should leave a gap at the edges. The thickness is usually taken with a finger. In the future, all this is embedded plastic moldings.

- Before the start of laying laminate should include a system, To create an atmosphere in the room. Laminate flooring is also within a certain time must lie in getting used to the room. These will allow all the subtleties even eliminate microstrain material.

observing technology, you can make installation of warm water floor without "wet" method. For this purpose the base of polystyrene or wood flooring. When you follow all points of the work can be done in-house. That will have a really high quality and warm up the ground in each room.