To economically and efficiently heat the subfloor in the room, should arrange a warm water floor quality. He will not require labor and costs during operation. In this case, the required temperature will be maintained at all times in every room. The heating elements must be placed in the dispensation of cement screed floor heating, to be well filled with the prepared solution of. Here you can do everything yourself, proportioning or buy ready for pouring the mixture of warm water floor. In any case, the composition for the screed floor heating water solution will vary somewhat.

Features of the solution

Using a mixture of warm floor by pouring concrete screed is somewhat different from those premises, where there is no heating. of the floor mode of operation is somewhat complicated, but, Consequently, requirements imposed to the solution increased. within screed Heated floor maintained under temperature 50 degrees. It becomes somewhat lower closer to the ground - within 30-35 degrees. Can occur following installation errors, if you do not follow the installation technology and poorly prepared solution for screed floor heating:

- Based begin to appear minor microcracks, which will only increase with the parameters over time.

This can subsequently lead to the destruction or damage to the floor covering.

This can subsequently lead to the destruction or damage to the floor covering. - Due to the emergence of a large number of cracks, begin skew cement layer screed. The heating elements will also be corrupted, and the work of the entire system will lose overall efficiency.

- Lowered temperature conditions, not only within the entire structure, but also about the base floor in the room. There were cracks have excellent thermal conductivity, and through them will leave the heat.

To all this was not in operation during water underfloor heating, prepared under screed fill the pipeline must have a certain set of technical specifications:

- Low period for setting cement. The probability of occurrence of residual stress will increase depending on, how much time there is a complete drying of the solution.

Besides setting process may vary: one portion still remains humidity, on the other - all dry.

Besides setting process may vary: one portion still remains humidity, on the other - all dry. - Slight porosity. The efficiency of the system water underfloor heating will be higher, if the density of the whole structure reaches the maximum score. This increases the thermal conductivity of the structure and.

- high strength. Cement sand screed underfloor must be able to withstand external loads and mechanical impact.

- Low probability of occurrence of cracks on the basis of. If this figure can be reached, the pipeline itself will not curve and damaged during operation.

Material screed

If we consider the version of the traditional screed for water floor heating, in the solution composition comprises cement and sand, dilute certain amount of water. The most important thing in this situation - to respect fully the proportion of each component, to get a really high-quality solution for warm water floor screed. This in turn will facilitate the preparation of the protective layer for the whole system.

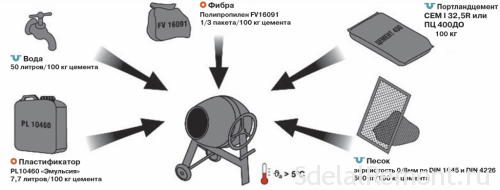

It is very difficult to obtain the necessary solution for screed floor heating, if to do without such modern means, as plasticizers or supplements, improving the quality of the fill. Furthermore, the surface of the tubes should have the same thickness the entire area of the room. These components help to get rid of excess water, weight and give plasticity to ensure a uniform composition ties warm water.

Depending on the amount of water, ties for water floor heating divided into:

- liquid. Have the greatest popularity. The homogeneous structure of the pipeline It is obtained by uniformly fill any voids in the base.

- Polusuhie. The amount of water in the solution corresponds to a minimum parameter. No harm will in such a case, instead of the layer reinforcement add special additives - fibrovolokno. By properties, it does not yield a metal mesh, but it gives the best quality of the finished solution.

Composition of solution

mix screed underfloor heating can contain not only standard, but also additional ingredients. In this case, there is no hard and clear indication of the total number. Special components can act as plasticizers, catalysts, hardeners composition. It is worth noting, that the overall structure will depend on, what option is selected for the implementation of the screed.

For liquid potting mixes typical classical variant kneading, which includes in addition to cement and sand more. The proportions in solution - 1 to 3. As soon as the mixture is added a certain amount of water, should get a homogeneous liquid mass. Can be added to the final solution plasticizers. Gypsum is not used in such mixtures for the reason, that the system is highly hygroscopic.

When preparing a large number of mixtures for fill screed over underfloor heating, the better to apply a concrete mixer, allows to obtain a homogeneous components. The actual process of preparation in this case would be less time-consuming.

For mixtures of moist warm water screed floor structure somewhat different. In addition, the preparation of the solution is carried out in two stages. Initially, mix the two components - sand and cement in a ratio 2 to 3. That is on 10 kg of cement required 1 kg of sand. In this, after thorough mixing, is added fibrovolokno. At the same order of size require a mixture of 15 g additive. On the resulting mixture to volume fill underfloor dolivaetsya 4 liters of water. Water should domeshivatsya gradually portions, to eventually obtain a homogeneous mass. the, what happened, shall stand for 20-30 minutes, whereupon domeshivaetsya second portion to the final solution - sand, water and fibrovolokno, in relation to 20 kg, 4 l, 15 g. I.e, Cement for the second time is no longer used. The resulting mass and is used for screed on warm water floor.

Calculate the required amount of materials to help tie online calculator solution.

preparation

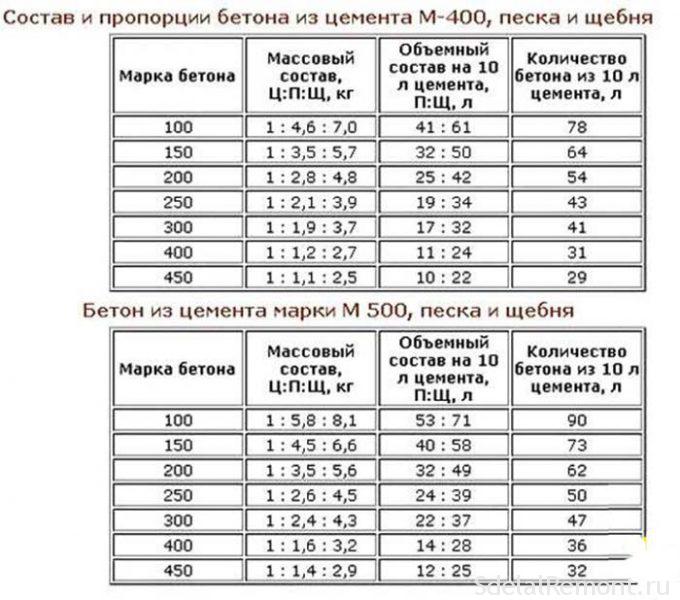

To floors turned durable, in the process of preparation of the solution is best to use a M400 or M500 cement. As for the sand to be added, it should have large grains, diameter about 0.8 mm. This will protect the surface from the appearance on it of cracks and other defects. The fine sand fraction is used for bricklaying is not the best option. When installing floor warm water required thickness of not less than 20 mm, depending on the type of screed. Take advantage Concrete volume calculator, to determine the quantity.

There is a caveat, which eliminates the liquid solution - adding water portioned. It is important to exclude the possibility of using too much water.

Dry cement mixture M300 peskobeton, are shown in finished form. There is no longer need to think about the proportions and getting high-quality potting. The dry mixture is only diluted with the necessary quantity of water, what is written on the instructions from the manufacturer.  Separately, very hard to get all the required components for the semi-dry mixture pouring warm water floor. For this reason, it is better not to experiment, and buy ready-made option for installation.

Separately, very hard to get all the required components for the semi-dry mixture pouring warm water floor. For this reason, it is better not to experiment, and buy ready-made option for installation.

For each type of mixture can go plasticizers, capable of giving the final solution over the qualities and characteristics of. Anyway, even if they are included with the purchase of, should follow specified on the packaging for this mixing. If it is difficult to determine the order, what mix screed floor heating choose, better to seek help from experts or representatives of the company.

makeshift solution

There are several options to perform a self-made solution for mounting screed floor heating water type. Among them are five primary, and which you should pay particular attention.  Basically, as constituents of the sand acts, granulated slag, plasticizer, cement, or all together in a single solution.

Basically, as constituents of the sand acts, granulated slag, plasticizer, cement, or all together in a single solution.

- When using a granulated slag, into the prepared container is filled with a portion of the selected cement, then 3 portions of sand and 2 - granshlaka. But the proportions will depend on, what brand of cement used in the work. To mark M200 will need to sand and cement in an amount - of 2 portions. Brand M500 - 4 portions of sand and 3 granshlaka. Here it is necessary to be very careful.

- "All inclusive". If all components are mixed in the same solution, additionally include a special reinforcing mesh of metal or plastic, the final base was not only reliable, but also very durable.

- The addition of the plasticizer. All components are stored in the proportions, as mentioned earlier, only intervenes additive. It will make the solution more tensile, and all the granules firmly bond with each other. They will not be "afraid" to a friend. On the packaging of the plasticizer has an indication of the necessary amount of the screed for underfloor heating water. On 1 cube mixture need to order 50-150 g plasticizer.

- Use as component fiberglass. For each cubic meter of final solution to tie water underfloor heating have to use order 600-800 gram fiber. Its length must be at least 12 mm. Composition of a solution and the appropriate proportions will. There just do not have to use granshlaka.

All of these options self mixing for pouring require the same amount of water per cubic meter of solution. It will take about 210-230 liters.

The nuances of installation

When the device ties of warm water floor it should be remembered, that there are certain subtleties, which must be known before the start of work. Used very high density solution, whereby reliable construction is obtained, the ability to withstand external mechanical impacts.

The solution may be used for arrangement of beacons on the surface of a base in the form of cones. Stacking beacons must be done in a straight line and with strict adherence to building level. According beacons carried stacking guide profiles, made of steel. All this will exactly and accurately fill future ties.

Pouring concrete is carried out on the exposed beacons, along the bottom edge profiles, which are subsequently removed. All possible areas with superficial damage to the floor should be sealed with concrete solutions.

We can not forget about the damping tape, serving as thermal expansion compensator configured screed. It is most often made of polyethylene foam. All of the following must be carried out only after complete drying of the solution.

Depending on the composition, will differ, and the time frame of the work. Tverdenye mixture with a smaller amount of water will be carried out considerably faster.

There may be cases produce not entirely flat surface, to produce flooring of floor coverings, as a carpet or linoleum. In this case, resort to additional leveling leveling compounds using. The layer obtained insignificant and does not affect the difference in the distance from floor to ceiling in a room. The maximum thickness of the self-leveling pouring comes to 5-7 mm. This indicator and should not exceed the elevation.

When arranged screed for underfloor heating proportion must be observed without fail. That it will get the desired result in the form of a durable and warm base.

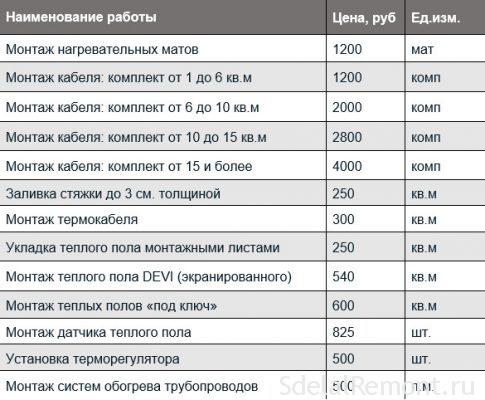

cost of

Price will depend on, the work is done on their own or with the assistance of experts. Generally builders brigade device when the screed over the warm floor water take-order 300 rubles per square meter. As regards mixtures for directly preparing a solution, their value will differ depending on the manufacturer and the basic components.

The most popular are a mixture of «Ivsil» brands, «Perfect", «Litokol», "Duration". The cost can vary from 180 to 500 rubles per standard packing weight 25 kg. It is very important when buying a mixture screed underfloor know, What better manifest itself in. Independently without experience hardly anyone would tell about it. Consequently, advisor in this matter will be experienced professionals.