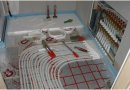

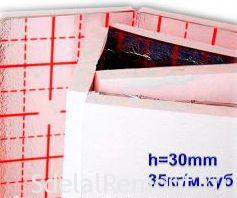

For warm water floor one of the most important steps is to install the thermal insulation layer. It is required for the air flow, coming from the heated conduit, and tie up, ie on the basis of sex. In this case, the heat is not consumed for heating slabs. It is the choice of a particular insulation material will depend on the total number of characteristics underfloor. In addition, mats for warm water floor must withstand mechanical stress and still maintain their appearance. This points to the need to purchase materials, having a density greater than 25 kg per m3.

Using

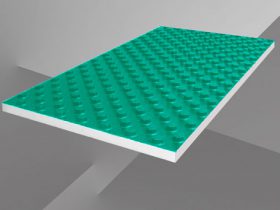

For underfloor heating are the most popular profiled mounting mats. In their base - foam with a density 40 kg per m3. The process is carried out in stamping gidropellentnoy, resulting in products, the ability to withstand mechanical stress, maintain their appearance, as well as to withstand hostile environments.  In addition, they have a specific base with relief, which perfectly fits to the pipe diameter 18 mm. No additional fasteners in this case is not required. editing process warm water floor does not take much time and it becomes easier and more convenient.

In addition, they have a specific base with relief, which perfectly fits to the pipe diameter 18 mm. No additional fasteners in this case is not required. editing process warm water floor does not take much time and it becomes easier and more convenient.

On the side surface of the mats for the floor heating, there are special locks, due to which they are stacked in a continuous web. No further action is necessary to make here. Moreover, on the lateral surface also has a line, whereby mats laying of floor heating together very well adjusted. The surface material allows smooth slight defects floor surface, create a protective layer against the penetration of noise.

An important feature of mats for floor heating - the complete elimination of heat loss in the process of the space heating system.

dignity

When the work on the installation of warm water floor using special mats, you can get a number of positive qualities, including isolated:

- For every product available in stores certificates for compliance, fire safety, sanitary-epidemiological conclusion, etc.. It's been said that, that for the quality of the material do not have to worry. They fully comply with the established European standards.

- The basis for the production of mats underfloor heating - Self-extinguishing materials, made on 90 percent of European equipment.

All this is also in line with all current standards.

All this is also in line with all current standards. - The basic material may be a dense foam board. It has high strength. All the original parameters of shapes and sizes are maintained even over a long period of operation.

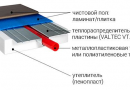

- Mats unlike special substrate for the warm floor water have extra laminated plate. According to the topsheet material has a film coating, performs also a number of additional functions.

- The presence of additional fastening sections, where pipes are placed underfloor heating. Pipeline installation for any of the selected scheme does not take much time.

- Due to the presence of markings on the mounting mats for warm water floor increases the efficiency of heat distribution in the room.

But this is only part of the advantages, possessed mounting mats for the heating system in the house. Without them, it would be difficult to get such quality and properties, and carry out the installation of the entire circuit.

types of mats

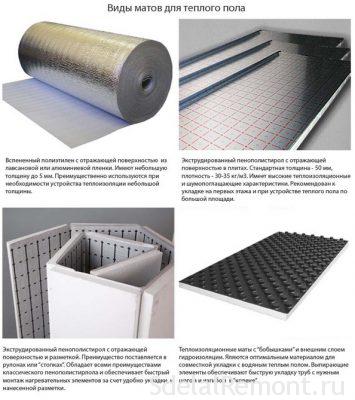

Classifications for mats underfloor heating there are many. All of them are divided according to the functions and qualities exhibited, mats as well as isolated whichever, how they are designed and produced as a.

- Mats with film. Here mats consist of three layers - polystyrene as the main constituent, foil layer and special film. Its density is sufficient for floor heating device and is approximately 30-35 kg per cubic meter. that editing process Matt was a lot easier, then it is marked with guides, allowing to join with each other. Clamps very firmly fixed pipe underfloor heating, since the density of the material is very high. They can be used for underfloor, as the main heating source in the room.

- foil products.

These mats are composed of penofol, foil having a coating on one side. But it is worth noting, that such material can be used for underfloor only, if it acts as an additional heating source in the room. Low efficiency when they are located on the ground floor with unheated basement. heating pipes to be laid on the other side, where the foil is attached. For fastening need to purchase additional elements in the form of collars, staples, etc., which causes some difficulties and problems in the work.

These mats are composed of penofol, foil having a coating on one side. But it is worth noting, that such material can be used for underfloor only, if it acts as an additional heating source in the room. Low efficiency when they are located on the ground floor with unheated basement. heating pipes to be laid on the other side, where the foil is attached. For fastening need to purchase additional elements in the form of collars, staples, etc., which causes some difficulties and problems in the work. - Made of polystyrene flat. Material thickness may be up to 50 mm, and density - up 40 kg per m3. This allows them to retain their shape and size parameters, even under pressure and external influences. For fixing also have to purchase additional fasteners. It is the best option in this case - special plastic brackets. For quality installation mats on the surface of previously executed markup. This increases the duration of the works and creates some inconvenience.

- With bosses. Here lies the basis of mat production stamping technology gidropellentnoy. This process allows you to get on the surface of the product Special shaped protrusions in neat rows. These projections are called bosses. If you still buy more advanced products, the laying process pipeline It does not take a lot of time.

Yet more attention should be paid is the last option for warm water mat floor, because their popularity is growing. They found the most practical application due to manifest advantages and performance.

profiled mats

About mat production technology with bosses has been said. They are presented in the form of rectangles, which begins on the thickness of 10 to 35 mm. The height of the projections on each plate is typically up to 20 mm.  The protrusions have a cylindrical shape or the shape of cubes. Between them can be carried out laying of the pipe system underfloor heating, the diameter of which reach even 20 mm. They are fastened so tightly and securely, that the concrete screed, even casting process does not move, but remain in the place, where they were originally recorded. They are presented in two forms:

The protrusions have a cylindrical shape or the shape of cubes. Between them can be carried out laying of the pipe system underfloor heating, the diameter of which reach even 20 mm. They are fastened so tightly and securely, that the concrete screed, even casting process does not move, but remain in the place, where they were originally recorded. They are presented in two forms:

- normal.

- laminated.

Laminated embodiments are covered by the additional steam insulating layer in the form of a film. In the presence of such a layer do not have to create another vapor barrier when the device of warm water floors. Among the drawbacks may be mentioned only the time, Such mats can not afford to make the flooring on them pipe with non-standard diameter. It may be noted are the qualities and characteristics of, which are profiled mats for floor heating systems:

- high density. This quality allows the material in the process of exploitation of withstanding mechanical stress.

- waterproofing. Furthermore laminating coating it is obtained by the presence of the locks of the centering, located on the lateral surface.

The surface of the individual plates is obtained a continuous and reliable.

The surface of the individual plates is obtained a continuous and reliable. - low thermal conductivity. The indicator is of the order of 0.037 – 0.052 W / m * K. This item refers to provision of reliable insulation.

- Excellent level of sound absorption and sound insulation.

- The main difference lies in the size of the mats for floor heating. Dimensions can be 1.0*1.0 m or 0.6*0.8 m. In addition, several different styling step pipeline on a surface. If the floor is warm at that site, where it is based on the ground or basement floor, it is necessary to choose a large width for quality performance.

Regarding the choice of mats to Warm water floor device, here should be based on certain points. Thickness plates must meet the finishing layer filling with flooring. We can not forget about a possible layer of insulation in the ceiling. If the thickness is suitable, you can buy and the base mat, because their primary function - a secure grip of pipes. In all circumstances, no heat loss from the heating system will not. All of it will be transmitted to the tie and in the future on the basis of sex, creating comfortable conditions.

stacking order

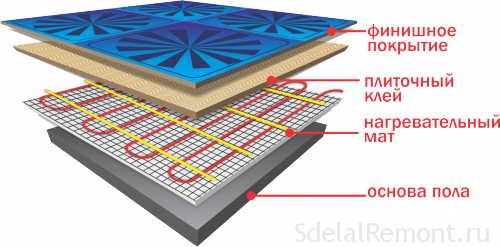

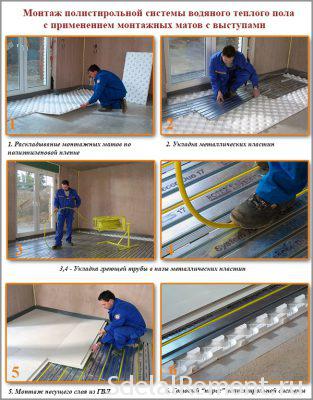

Regardless of, what kind of mat is used for system device water underfloor heating, in any case to be arranged waterproofing layer of polyethylene film. In addition, further on the perimeter of the walls to fix the damper tape.

When the training carried out, you can start to produce flooring mats on the surface, connecting them together locking system. If the weight of the little mats, and thinness, it uses a special adhesive compound, whereby the elements are interconnected.

In such a case it is necessary to dispense with the metal fasteners. Otherwise, the integrity of the layer of insulation material is breached, and waterproofing layer. So what you should forget about such fasteners, like screws or nails. In the application of the foil boards, their field joints should be glued with tape. May further rascherchivatsya markings on the surface of certain embodiments of mats. When it's all done, you can begin to work on mounting water floor heating circuit or circuits. For this specific arrangement chosen pipes ("Snake" or "snail"), or combine each of them in one room.

Right choice

When it comes to selecting mats laying water underfloor heating, it should be placed on certain points:

- require certificates. Every seller on their products must have documentation, confirming its high quality. In addition, the warranty provided by the seller must be exposed. Otherwise be encountered counterfeiting, that only cause negative display during operation. Loads of cheap foam is unlikely to survive.

- Selection mat thickness will depend on future ties and its layer with a floor covering. In a preliminary alignment of the subfloor will be enough to buy a thin options, equipped with lugs for better installation. Such mats under floor heating will have a better performance.

Immediately better to buy laminated products, not only suitable for dry, but also semi-dry screeds.