Deciding to make installation of warm water floor in the house - the surest. This creates a huge comfort and convenience. With it you can walk barefoot on the floor and not be afraid of the cold. But before laying should be to choose the right version of the screed under it. Efficiency will be reduced because of the large fill layer, and very thin in this case rapidly crack and lose all its qualities and properties. Consequently, screed must be of high quality and meet all the requirements of reliability and durability.

the need for tie

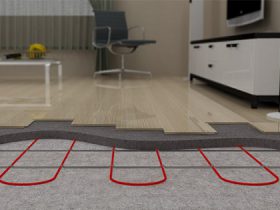

Installation of the heating system can not do without the device reliable ties.  Ready solution filling all voids and protects them from external impact and the possible mechanical damage. Heat is not lost, and all completely transferred upward, from floor to ceiling.

Ready solution filling all voids and protects them from external impact and the possible mechanical damage. Heat is not lost, and all completely transferred upward, from floor to ceiling.

If you add a concrete mortar special additives, plasticizers, they will avoid the appearance of bubbles after filling. This increases the density of ties, as well as properties of thermal insulation material increases. The outer part will be used for finishing or decoration.

Screed for floor heating than the protective function of pipeline damage, perform the function of a uniform distribution of heat throughout the room, where the installation is made. Additionally supports downstream soundproof rooms.

types ties

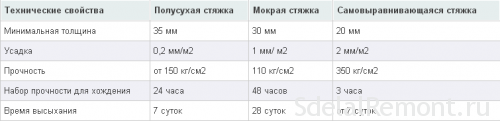

There are several basic types of ties, which can be used to warm the device water floor:

- Cement-sand. Virtually identical qualities has concrete screed water underfloor heating, having a similar casting technology.

For preparation of the solution used sand and cement, as the main components, and also may be used and various additives, improving the quality of the entire casting. Not adding the rare cases in the PVA glue solution, increasing flexibility and excellent spreadability on the surface.

For preparation of the solution used sand and cement, as the main components, and also may be used and various additives, improving the quality of the entire casting. Not adding the rare cases in the PVA glue solution, increasing flexibility and excellent spreadability on the surface. - Self-leveling mixture. Of the most commonly used for finishing and to create a perfectly flat surface.

- Polusuhaya screed. The technology differs little water.

Pre is to determine the order, what warm water floor screed It will be optimal for certain conditions. All will depend on the degree of irregularities in the substrate, mounting process complexity and other factors.

Preparation of the base under floor heating

when you select concrete screed for execution, it is very important to carry out a number of preparatory activities. The surface must be aligned under the horizontal level. Especially it concerns areas, where there are differences in elevation more 10 mm. We can not forget about the layer waterproofing. Along the wall around the perimeter of the damper strip is fixed in the room, serving for temperature compensation of future ties. Upon heating the solution has a property to expand. To prevent damage to the walls in this case, and applies damping tape.

The warm water floor can be used multiple paths to improve the quality of premises heating. In this case, the damper produce packing tape and the line between them.

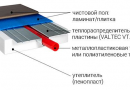

Based on gender should be a quality insulated, to heat under no circumstances be rushed down, and received only through the floor of the room to warm up the air. Warming will depend on the location of the premises, depending on the circuit itself and use warm water as a main floor or additional heating source.

When Heated floor acts as an additional element of the heating system in the building, then as a material commonly used polyethylene foam. He also should have a foil coating, which will reflect all the heat from the heating elements toward the floor.

The first floors of buildings, if there are also cellars no warm-up, as well as the location of the premises House directly on the ground is better to get more serious insulation - the embankment of expanded clay, polystyrene sheet with a thickness of 50 to 100 mm. This will significantly reduce heat loss.

When Warm water floor It arranged in the rooms on the second floor and above, as well as the first, if there is a cellar with heating, it can be used for thermal insulation in expanded polystyrene. An alternative to such products - extruded polystyrene. Usually a thickness selected from 20 to 50 mm. You can choose other options for insulation, the main thing that was appropriate thickness.

In the construction market are presented and special insulation, are meant directly for the device underfloor. They contain special channels on the one hand, which will be placed pipe system. The entire installation process will be much faster.

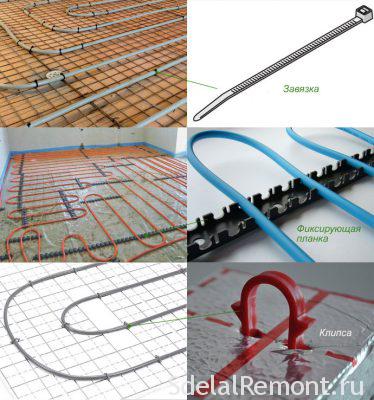

If no special channels in the insulation, floor heating pipe can be fixed with clips and clamps to the reinforcement layer. It is usually made of metal mesh with the respective cell diameter. Used screed for underfloor heating has its advantages, due to which and in demand in the construction industry.

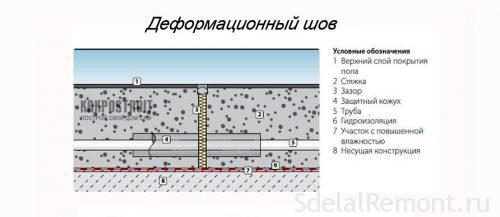

Expansion joint

We must not forget when casting the screed warm water floor device about the expansion joint. It can run in the following cases:

- When room available with a complex configuration.

- The openings of the input or interior doors, or rather under the threshold location.

- When the wall is very long, more 8 m, as well as in cases throughout the room ratio of the width to its length is less than, than 1 to 4.

Possible and in other cases to arrange expansion joints at this stage, the main thing, all yield positive results for the. In this case, the main thing to choose the right seam height. It must match the selected thickness of the concrete ties, which is chosen to fill the under floor heating. Attention is drawn to the fact, that the upper part of the expansion joint, its boundary, It must be located in the wrong place, wherein finishing flooring in the room will be.

It is worth noting, that there are nuances when laying mesh for reinforcement of metal tie warm water floor. It must at all times be interrupted at the location, which will be located in the premises of expansion joints.

Purchase of material

Screed for floor heating must be performed in the presence of certain materials. They can be purchased at any hardware store. It is understood that, that ties need one set of products, and another set will be needed for a quality installation of warm water floor. Particular attention should be paid when selecting it pipes. Their quality will depend on the efficiency of the entire system after installation. Some have greater value, as copper or stainless steel, but they have a sufficient set of positive qualities and characteristics. If the choice fell on polyethylene pipes, the investments will be at a minimum. But there may be some difficulties in the process of installation works.

Materials for the tie will depend on, what option is selected for execution. This cement with sand, filling the sheet material, or special construction dry mixes, which need only be diluted with the desired amount of water. It is necessary to understand and know when, How to determine with screed for underfloor heating, What better materials and equipment purchase.

The thickness of the screed

from ties thickness All will depend on the floor heating system exhibited quality. Typically draft of selected thickness corresponding 50 mm. The thickness will affect the purpose of the premises, wherein water is performed under the floor screed.  Spaces layer allow the device 50-70 mm, and industrial facilities due to high external loads must be screed, reaching even to 100 mm.

Spaces layer allow the device 50-70 mm, and industrial facilities due to high external loads must be screed, reaching even to 100 mm.

In such a case should proceed from the fact, why all targets strainer for a warm floor water - heat storage. It's been said that, that a thin layer of screed not be able to retain heat for a long time. Consequently, the system will constantly operate and transfer energy. The boiler increase, to maintain the required temperature. The optimum thickness of screed to a floor of warm water - 70-80 mm. It'll be enough, to have optimum heat level indicators in the room.

Composition for filling solution

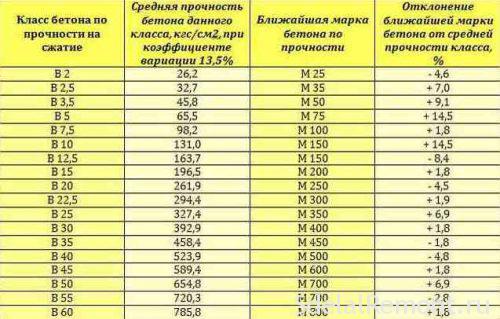

To the heated space from the subfloor need to prepare carefully solution, compliance with all proportions. In order not to waste time on it, you can buy ready-mix and add to it a certain amount of water, following the guidance and instructions. Used concrete must have a mark within M150-300. All will depend entirely on the loads generated during operation under a warm water base floor. The housing is usually sufficient and M200, but the industrial facilities require M300.

When independent manufacturing mixture, should adhere to the established proportions. 1 part cement has acquired kneaded with 3 parts sand. Sand takes a fraction of no more than 0.8 mm, better solution to spread over the surface and do not create unnecessary roughness after fill. An alternative to sand - granotsev, which creates a more durable solution. But then there will be change and the proportions, instead of the three parts of sand, You need to pour 6 servings granotseva. We should not forget about water. As a result, should get a liquid consistency solution. Usually it is taken 0.8 parts.

Plasticizers allow to become screed more supple, that will be especially marked by heating. If you do not want to go to stores and spend money, that is, and folk remedies, able to replace them:

- PVA glue. Per sack of cement required 1 kg adhesive.

- liquid soap. It is added to a smaller number of, order 150 grams per sack of cement.

Fill beacons ties

When the surface is ready for operation, pouring the kneaded can be carried out of solution. But it is worth remembering that, it is necessary to put beacons on the indoor level. Only in this case under the screed Warm water floor Get the highest quality. The best option in this case - the usual mortar mounds, reaching the level of the whole casting. Carry out the whole process is very easy and will not be difficult, even a novice builder. The main thing in the use of appropriate tools for the horizontal level. There are commercially available and ready beacons, which need only be positioned on a plane in the room.

Concrete for ties underfloor heating after casting should tamp. For this purpose there is a special equipment, which can even be rented for activities nonce. In this way, therefrom expels the air bubbles. If it does not perform, the reduced level of thermal conductivity of the future floor heating. That is, the process does not require tangible knowledge, but only the application of labor. Similarly, the installation is carried out in the finishing screed as already immediately after the installation of warm water floor. Already in the finishing option required to make the location of the expansion joints.

Expansion joints

All seams must be carried out in areas with a large area of more than 40 square meters. For reinsurance is done in smaller rooms. Sutures intended for, to avoid the appearance of cracks on the surface during operation of the system warm water floor and supplying elevated temperatures. Additionally defects may impact on the quality of the floor covering.

Needless expansion joints in the blister pouring device. It comes from the fact, that between it and the floor heating system is a layer of insulation. To say in simple language, the seams are damping tape, which is located just in the middle of the room in the screed.

Self-leveling mixture

For underfloor heating systems can be used self-leveling mixture. In this case, need not perform the installation guide.  After mounting all components of the system of warm water and cleaning the floor surface from debris, fashionable underpour prepared solution. The main thing in this case, strictly adhere to all the proportions, to get high-quality surface. Thickness over the tubes should be less than 30 mm. To evenly distribute the mixture over the surface is better to use a wide spatula.

After mounting all components of the system of warm water and cleaning the floor surface from debris, fashionable underpour prepared solution. The main thing in this case, strictly adhere to all the proportions, to get high-quality surface. Thickness over the tubes should be less than 30 mm. To evenly distribute the mixture over the surface is better to use a wide spatula.

They are exactly the same manner and can be used under the warm water system of the floor to create a level surface to the contours of the pipeline.

Professional advice

During the work on the device ties under the system Warm water floor should adhere devices Technology, as well as tips from experienced craftsmen. They have often faced problems and help solve each of them.

Screed floor heating is best to start producing after, both made all the work on the plaster of the walls in the room. You can not at the same time forget about fixing the damper tape, not allowing to collapse the whole "pie" in the operation of warm water floor.

Before preparation of the solution or mixture for casting should produce exhibiting beacons on level. This will achieve a perfect horizontal surface for the subsequent installation of the entire heating system in the room.

When the room has a large area, it's worth thinking about, to arrange expansion joints, represent the same damping tape, but the room perimeter, and about halfway.

Having considered all of these embodiments of the apparatus, you can determine the order, what is needed screed for underfloor heating. All factors should be provided prior to the start of work, so that in the future there were no difficulties and problems.

If you comply fully with the technology of filling the rough screed, further installation of floor heating system water and finishing flooring screeds, the result will be the most joyous - the heat will flow into the room from the base and will be comfortable to walk on the floor bare feet, even. It will be increasingly felt in the moment, when to enter the room from a cold and feel heat gain.