Everyone wants to arrange a room in your warm water floor due to the large number of positive qualities and uniform heating of the room from the floor. But not all the rooms can afford to perform the fill of concrete floor screed. In this case, settling a warm floor without casting, which reduces the cost of preparing the solution, and the assembly process and the waiting time until complete drying. Additionally without tie device used is not lost space between the ceiling and the floor, and the whole process takes a short time.

Types of sex without ties

This version of the device of warm water floor is perfect for those spaces, where in certain circumstances it is not possible to produce a fill concrete screed. Most often it is a wooden structure, rooms, which is already very low ceilings, and there may be situations, when the problem is in the delivery of concrete to the place of work.

There are several options for the device warm floor without ties.  There are two kinds of them:

There are two kinds of them:

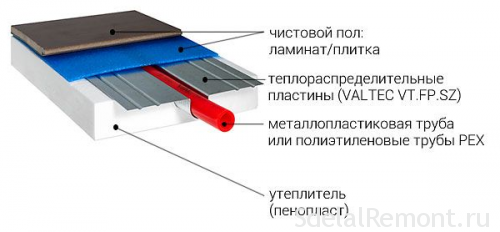

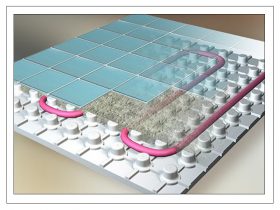

- polystyrene. Underlying the floor - laying mats of the appropriate material (polystyrene). We must not forget, in this case about self heating circuit, which can be placed under various schemes. Used when installing joists can be installed not only on the joists, wooden base, but the previously formed concrete floor to planarizing.

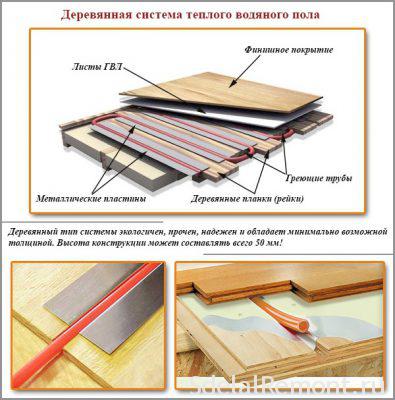

- wood. Here used wooden plates, on one of its sides special channels located, where pipes are placed. This system can be mounted in the same way, as polystyrene.

The easiest is considered polystyrene system. But in this case, a large load bearing beams. All these details should be considered prior to installation process. It is not superfluous to conduct a pre-calculations. As the fixation elements pipes warm water floor Aluminum plates used.

In the absence of concrete screed need to make installation of the thermal insulation layer. Most often, experts recommend to get dry materials, eg, mineral wool. There are also more modern products - gipsovolokno.  Furthermore the sheet material excellent insulating properties possessed by all kinds of fillings.

Furthermore the sheet material excellent insulating properties possessed by all kinds of fillings.

Technology does not stand still and is constantly allowed to market a growing number of new methods and ways to arrange a warm water floor. It as insulation material polyurethane began to apply, but not in its natural form, as by spraying on the surface. The paper is used in a spray bottle.

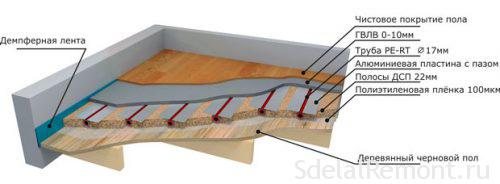

When the wooden base in front of us, then stacked on it galvanized steel plate. further there laying substrate polyethylene, to prevent crack parquet boards after their flooring. If the cover after installation of warm water used linoleum floor tiles or cable, the substrate as the most popular are sheets of GOLS.

Benefits

By selecting device of warm water floor without fill screed, each will receive a certain set of positive qualities, which include:

- Selecting any grounds for the heating system.

- There will not be a serious reduction in the height of the room due to the small thickness of the "pie" in construct.

underfloor heating layers without tie - Insignificant load on the slab or another reason. Especially important for old buildings or the presence of a wooden house construction.

- Regardless of the type of overlap can be made this design, because it has almost the total weight on the basis of pressure.

- To flooring topcoat can begin immediately after the installation of the selected embodiment of the device underfloor heating without ties. You do not have to wait for time to dry concrete screeds.

- Minimal occurrence of dirt and dust and the complete absence of water in the process.

Application plank structure

Scope plank design quite wide. But we should remember about the opportunities, at which it can be implemented. According to the design decision may not be possible to reduce the distance from floor to ceiling. In such a case may be affected and all the other elements in the room.

Ready concrete problem to deliver to the floors of multi-storey buildings. Consequently, Here we have to consider other options for the device warm concrete floor without fill screed. Even on the ground it is very difficult to perform kneading the required amount of solution.

Can not be made concrete screed in such buildings, as a frame houses, home of the log, and shield. When using dry system overall weight of the structure decreases nearly 10 fold compared with a concrete solution. In the latter case also the added height of approximately 5-7 cm.

But without fail will have to arrange waterproofing, because the dry material is very susceptible to humidity.

materials

If you need to perform a warm floor without pouring concrete, you'll need to visit the hardware store, where to buy relevant material.  Here, special attention is paid heating pipes, over which will have to perform a moisture proof flooring mats, produce flooring flooring of any kind. Even little things prompt, how to make the high quality radiant floor.

Here, special attention is paid heating pipes, over which will have to perform a moisture proof flooring mats, produce flooring flooring of any kind. Even little things prompt, how to make the high quality radiant floor.

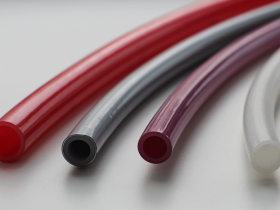

Among the pipes are in demand polypropylene and polyethylene products. If desired, to obtain high quality and reliability of the whole structure, will have to spend some more funds and buy copper pipes or stainless steel pipes.

As the coolant can be used not only ordinary water, but antifreeze, since no damaging effects they have will not be able.

For thermal insulation is best to buy a plate of expanded polystyrene, which additionally provides a barrier for the care of heat into the lower portion. As the plate is easy to carry out laying of pipes due to the presence of special grooves or protrusions. Step, arrangement of the elements relative to each other, You can be selected independently on the basis of the destination of the premises and the desired result. For mounting plates, the lock.

Modules can be wooden. They also provide for the appropriate channels, to make it easier to perform the installation of pipes. The width of the plate is selected depending on the pitch of laying.

polystyrene base

Pre is to determine the order, what kind of pipe system mounting method is chosen warm water floor.  This can be a spiral, snake or choose a combination of these schemes in the same room in order to achieve maximum effect.

This can be a spiral, snake or choose a combination of these schemes in the same room in order to achieve maximum effect.

Thickness of the polystyrene plates typically standard in 30 mm. If insulation layer It needs more, You have to use several layers of material to work. But before that produces high-quality alignment of the base. All variations and errors must be eliminated, and removed all possible garbage and old screed, old coating, etc..

The plates can be completely different: have grooves, be straight or pivoting. Each of them has a special lock, by which they are attached to each other. The average arrangement pitch of the plates is 15 cm, but you can buy in 30 cm.

In carrying out the work important not to get lost in the, how to arrange a pipe system in a warm water floor. The complexity of circuits is increased by selecting a particular type of board. For this purpose each pre-slab is numbered on the basis of sex, to the right to make their flooring. But the final result will be more efficient.

material for warming It requires up water pipe system underfloor arrangement laid metal plates. Always worth sticking of the plan. Then go to the top substrate, which is arranged on finishing. For other than the parquet and laminate coatings should adhere to certain rules. Under the tile is dry screed of sheets of plywood, plasterboard or chipboard sheets.

Flooring made of wood

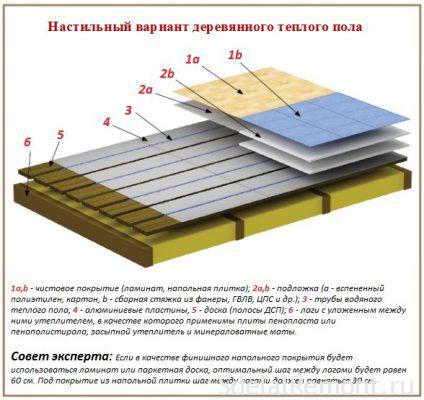

This technology is provided mainly for wooden buildings. There are then several of his ways:

- The basis of the rails.

- Based modules.

That second embodiment and more popular due to the application of the plates, in which slots are already provided for the pipeline. Besides work without ties significantly reduces the timeframe completion of works. When a big hurry, some will not be able to wait for the complete drying of the solution and make laying the pipeline. But in any case it is impossible to mount the floor heating in the water finished screed.

Pre-based floor made with the selected location lag step. Therebetween plank material and hydro insulation. On top of the distance 20 mm mounted boards of wood. This distance must be maintained to compensate for expansion of the elevated temperatures.

For strip method need to carefully prepare the subfloor. Overall installation of pipes should be provided in advance and follow it during installation. Placing rails performed sustained distance for fixing the pipe loop, arranged on the metal plate.

Finish may be completely different thicknesses. With a thickness of up to 10 mm it can be placed over the plates, but not forget the insulation layer. To prepare the surface of the tiles: stacking sheets produced chipboard or plasterboard. In this case, the joints must be processed to obtain a smooth surface without flaws. It was under the tiles in the ground and arrange warm floor, to thoroughly warm it in the kitchen, in the bathroom.

Possible mistakes

During installation of warm water floor is not uncommon for masters permitted errors, especially beginners. To avoid this is necessary to consult with experts and they clarified all the possible difficulties of working, how to get a warm floor, requires not screed.

To answer that, how to make a warm floor without concrete screed, originally should measure the entire structure. It also carried out and at the end of work.  About him many forgotten or considered inappropriate. In fact, the step makes it possible to find serious violations, which can be eliminated before the onset of. If you leave it as it is, then over time, in any case will damage, or will be spent more put energy. In this carefully calculated in the subsequent possible pressure on the subfloor.

About him many forgotten or considered inappropriate. In fact, the step makes it possible to find serious violations, which can be eliminated before the onset of. If you leave it as it is, then over time, in any case will damage, or will be spent more put energy. In this carefully calculated in the subsequent possible pressure on the subfloor.

Temperature sensors over time require replacement operation. If they are arranged in a structure depth, then there will be problems to get them, and then install the new. In addition, it will be easier to periodically check its serviceability, if the access to it will open.

We can not allow haste during the warm water floor system installation. This is especially important, if the installation is carried out in water underfloor clay filler or other wet screed, when the time required for curing solution. Premature inclusion in the operating position of the system lead to damage to the entire structure.

Proper screed for underfloor heating water saving abhors. Good materials will provide a truly effective system of, which will increase the operational period. Substandard products will lead to a speedy breakdowns, failure of individual components. For repair will spend more money, than pre-buy quality products, but at a higher price.

By selecting a specific technology of warm water floor installation, you must follow it to the end. The process itself does not tolerate deviations and will only serve to damage the entire circuit or separate sites. But this installation option without screed provides a lightweight design, which can easily produce a decking of any embodiment of the floor covering.