Mainly for private home use system underfloor heating water type. Also often as flooring tiles is chosen. It creates a beautiful appearance, but it has an excellent thermal conductivity. Tiled floor in such a case requires careful heating, with which easily copes floor heating. Average heating radiator can not transfer as much heat on the base, so it was comfortable for walking. Heated floor tiles and very well with each other. There are different water-floor installation system.

Mounting options for floor heating

Initially, it is worth thinking about, how best to make laying of floor heating, what option to choose this.  Pavement can be made with a floor screed, grazing method (without concrete screed), as well as the wooden sleepers (Installation is carried on top of the lag). Each of them has its own peculiarities and subtleties in the work.

Pavement can be made with a floor screed, grazing method (without concrete screed), as well as the wooden sleepers (Installation is carried on top of the lag). Each of them has its own peculiarities and subtleties in the work.

Concrete ties will need to purchase a specific set of materials for work. All that will have to be in the future - to carry out the construction of the water pouring warm floor under the tile grout. In this case, everything must fit technology. In the presence of defects or voids in the base, We have to do all the work again. When I laid screed, it takes time to complete drying. Only after this can be done tile laying on the tile adhesive. To heat is evenly distributed across the surface of the floor, the thickness of the adhesive layer itself and tiles should be smooth.

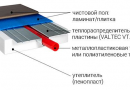

The method of grazing used polystyrene plates, having an aluminum plate with grooves, in that and put pipeline selected mounting step.  The costs in such a case as low, and the very process of laying hot water under the floor tile does not take much time. If it will be necessary to produce the clutch cover, then as a basis is best to use water-resistant material, such as sheets gipsovolokonnyh. Polystyrene is more suitable for laminate or parquet.

The costs in such a case as low, and the very process of laying hot water under the floor tile does not take much time. If it will be necessary to produce the clutch cover, then as a basis is best to use water-resistant material, such as sheets gipsovolokonnyh. Polystyrene is more suitable for laminate or parquet.

For wooden houses are in demand floor heating device on logs. There also are two more subspecies - rack or modular. When the installation is made fully, on top of the whole structure of the stacked sheets gipsovolokna, then given the opportunity to carry out laying tile.

Substrate preparation

When the hands have the necessary amount of material for, especially components warm water floor,  it is possible to start preparations. The surface must be free of foreign objects, trash, dust etc.. each stage fill screed under floor heating and it, It requires strict adherence to technology. Each stage should provide a perfectly flat surface.

it is possible to start preparations. The surface must be free of foreign objects, trash, dust etc.. each stage fill screed under floor heating and it, It requires strict adherence to technology. Each stage should provide a perfectly flat surface.

The process of filling It will depend on the choice of. When choosing a floor heating water, which one is better able to consult experts in this field of construction. In addition, they will be able to tell the sequence of all the works, even in the preparatory phase.

Installing the collector group

In addition, to be distributed all components warm water floor. Start talking with the installation of the collector in the collector cabinet.  The cabinet can be located anywhere, which will be more user-friendly. Yet it is attached to the wall, vertically so, that was above the heating surface level. It will be possible to connect several circuits, if it is needed. Most often, this is done in the presence of a large area of the room. Everything heating tubes connected to the main source of, and made the installation of devices for temperature and pressure control modes. Here, the circulation pump is located, enabling constant flow temperature of the floor heating circuit.

The cabinet can be located anywhere, which will be more user-friendly. Yet it is attached to the wall, vertically so, that was above the heating surface level. It will be possible to connect several circuits, if it is needed. Most often, this is done in the presence of a large area of the room. Everything heating tubes connected to the main source of, and made the installation of devices for temperature and pressure control modes. Here, the circulation pump is located, enabling constant flow temperature of the floor heating circuit.

The system can be switched off completely by means of specially installed valves. To this valve itself and attached manifold.

And hydro insulation base

Under Warm water floor, which will in the future to lay tiles, It should be arranged qualitative heat and waterproofing. Ideally suited for waterproofing sheets of aluminum foil or polyethylene film. Foam insulation may be, on one side of which is fixed a film of aluminum. by the way, the latter material will be sufficient to perform both functions of the base under floor heating.  It is worth noting, it is better to warm water floor, than the radiator battery. He could not spoil the aesthetic appearance, and create a comfortable environment.

It is worth noting, it is better to warm water floor, than the radiator battery. He could not spoil the aesthetic appearance, and create a comfortable environment.

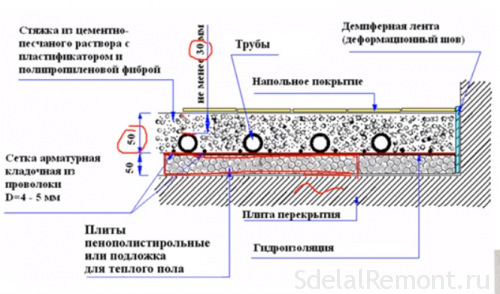

We must not forget here about the damping tape, which in the finished product can be purchased at hardware store. It should be mounted on the wall around the perimeter of the room at the level of the future pouring concrete screed. The thickness is usually taken in 5-8 mm, and height - up to 15 cm. You can not be afraid to fix it more and more. Subsequently, all very easy to cut with a knife. With self-manufacturing of belt is best to attach it to the wall with screws for reliability. This all is done for the reason, that heating concrete has a property to expand by about 0.5 mm for every meter of surface.

Fixing the heating circuits

Insulation is best to buy a special floor for warm water.  This is due to the fact, that it has the appropriate slots, in which the attachment pipeline. But it is very important to purchase the correct version for your device tubes heated floor. In the market represented a huge range of. Additionally reinforced plastic, There are also copper and stainless steel. Yet more interest and popularity has material XLPE, with sufficient set of positive features and operational characteristics.

This is due to the fact, that it has the appropriate slots, in which the attachment pipeline. But it is very important to purchase the correct version for your device tubes heated floor. In the market represented a huge range of. Additionally reinforced plastic, There are also copper and stainless steel. Yet more interest and popularity has material XLPE, with sufficient set of positive features and operational characteristics.

When such grooves are not available, the reinforcing layer is arranged, which pipes are fixed and the entire system. Additional reinforcement layer may be arranged on top and the tubes. In this case, the reliability of the entire structure significantly increases.

There are other options to mount the pipe filled with concrete screed. This is a different fasteners in the form of collars, latches. In any case it is necessary to adhere to installation technology, where indicated, what tubes They must be located no closer 10-15 cm from the wall in the room. Besides the standard step is selected 10-12 cm. loop length should not exceed 10 cm.

An important stage - selection of a particular scheme, allowing the pipeline to perform fastening on the subfloor. This can be not only purely "snake" or "snail", but combined, When combining both options in the same room. In the latter case, all is done to improve the quality and efficiency of the entire floor heating system. Since the "snake" does not possess all the good qualities of the presence of floor heating only coolant exit area, the experts recommend arrange a double "snake". All this has to be previously displayed at the circuit diagram, to subsequently been easier to carry out its connection to the collector. In addition, this option will allow the correct and accurate estimates of the number of components underfloor heating. For a more accurate calculation of Use calculator warm water floor.

testing the system

If the system is designed, before pouring the concrete screed, it must be checked for serviceability and tightness of all connections. crimping occurs (pressure test).  This step will allow to detect all defects installation of warm water floor, that could subsequently occur after flooring tiles.

This step will allow to detect all defects installation of warm water floor, that could subsequently occur after flooring tiles.

The entire system must be filled with water and pressurized, which is about half of the more than, than the normal operating pressure. You can additionally be used for best results an air compressor. All carried out for at least days. the main thing, that nothing be manifested. Better to wait an extra day, but be sure, everything works debugged. Otherwise, when it meet the surface of the tiles, will have to make its dismantling and removal of the screed to the hospitality area, to repair. But alone it will be difficult to eliminate all without extra costs.

screed

Tile importantly qualitatively arrange concrete floor. Usually it is the height 30-60 mm. It is worth remembering, that the floor covering can be laid only after about 1 months after the grout.  During this time it occurs drying and setting of cement. In some cases, produce measures to accelerate the drying process. To do this, turn on the heater in the room, but the temperature should not be more 25-30 degrees. Otherwise, an uneven surface drying and drying. But the best option in this case - a natural drying, when there is extra care screed. Better to wait an extra week and not have to worry about the quality.

During this time it occurs drying and setting of cement. In some cases, produce measures to accelerate the drying process. To do this, turn on the heater in the room, but the temperature should not be more 25-30 degrees. Otherwise, an uneven surface drying and drying. But the best option in this case - a natural drying, when there is extra care screed. Better to wait an extra week and not have to worry about the quality.

Reduce the time of work on top of the floor screed underfloor heating for laying tiles allow self-leveling mixture. It will be ready after only 10 days after installation. More precise time-frame prescribed by the manufacturer on the packaging, and what should be consulted prior to the works.

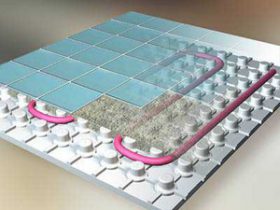

Laying tiles

No special conditions for, to implement tile laying Heated floor in water. There correspond to any other surfaces.  It is important to include the right underfloor heating after installation and during operation to monitor the temperature regime.

It is important to include the right underfloor heating after installation and during operation to monitor the temperature regime.

As binder used a special tile adhesive for floor heating. He should be able to use the system underfloor heating. Typical embodiments of adhesive can not withstand the constant temperature changes especially at coolant temperatures uncontrollable.

Gluing is done with a notched trowel. The height of the teeth depends on the layer of the connecting element and floor tiles. Once the adhesive is applied to the back of the tile, it should be pressed to the floor and a little squeeze, by holding for a while. Do not be amiss on a horizontal surface using a spirit level. In some cases you will have to press one side closer to the bottom, to squeeze out excess glue.

For flatness seams special crosses between the tiles used elements, which may be of different widths. They are installed after laying tile on the floor warm water in the corners. Later they removed, and upon drying the adhesive is performed grouting. The adhesive can dry for even two days. All this is also spelled out in the recommendations of the manufacturer.

In the process tile flooring at the base of the concrete screed for warm floor, the whole system must not be in working order. Everything shuts down before the end of work. It turns on the warm floor after laying the tiles and complete drying glue. When produced grouting, It begins full operation and floor heating in the room.

cost of

As for the cost, not only the system of warm water floor, but the tiles, laid on the surface, then everything will depend on certain factors:

- Purchased fitting material, manufacturer, mark, quality. But no one does not recommend to save on such a system,. After all is done not for a year or two, and for decades to come. Better once to buy all quality, than later to spend money for repairs.

- The cost of the collector group. More expensive versions of products have the ability to automatically adjust the temperature level in the room and the pressure in the circuit.

- on the device concrete screed works, complete align all surfaces.

- Installation of floor heating, which is often carried out Specialized teams.

Averages prices per square meter of warm water floor is 1500-3000 rubles. This includes material already and all installation work. If the work will be carried out not only in one room, and in the house with a large area, the cost of the work will be slightly reduced. The total cost should be calculated individually. Favorable warm floor will turn out at independent performance of the entire process from start to finish. But for this purpose the necessary amount of experience and knowledge.

Flooring tile as, as well as directly the radiant floor heating excellent interact. It delivers high-quality heating material, and tile itself is great for walking on it barefoot.