Almost all residential buildings can be equipped with a warm water floor. But especially the buildings will have an impact on the characteristics of this type of heating device. The most important thing to stick to technology, to have available a complete list of materials for the installation, as well as to choose the optimal variant of the system, which will be used to obtain the desired result.

system Selection

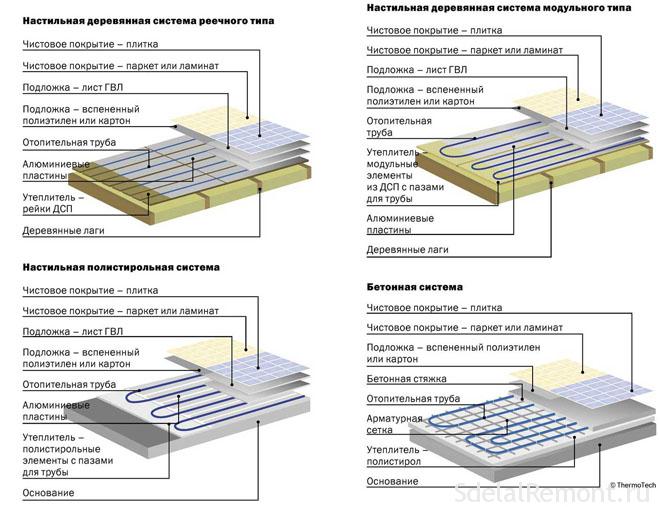

Depending on the specific conditions should be chosen mounting technology underfloor heating. This will have an impact beams of the ceiling, his condition and the type of, requirements to the base floor, operation created in the process of loading and more. There are major systems, allowing the water to get warm floor in the room:

- Device screeds water underfloor.

- Nastilynaya system.

- wooden system.

Particular attention should be paid to it concrete screed, as it is increasingly used in reality. If you take the quality of heating, here, too, it has a better use and efficiency in the work. You could even say that, that the qualitative arranged shading can cool within three days after the full warm-base. Even if there is a power failure or coolant supply. Heat is still a few days will be transmitted to humans.

In those areas, who can not afford to make a concrete screed, use the other two, having its positive aspects and certain disadvantages when used.

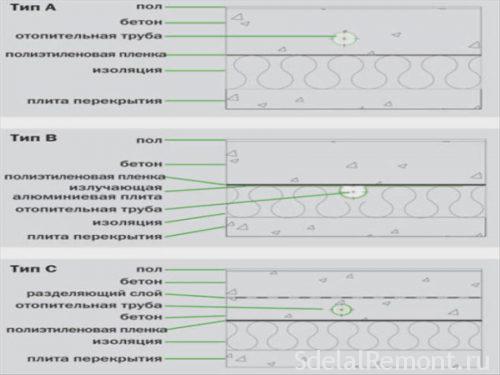

The types of devices with a concrete screed

When the choice fell on installation of warm water floor with concrete screed, it should be remembered that, that there exists just three basic types, which are determined depending on, as the heating loops are placed in the overall "pie" floor. In some cases, in addition to full fill the base of the concrete solution, It can be used dry backfilling (often expanded clay), to reduce the overall load on the overlap.

Type "A". This type is the easiest of the thermal floor unit and less demanding on work. On the slab is arranged an insulating layer, and produced stacking from polyethylene film. Further heating pipe System Warm water floor is laid directly in the concrete screed. Will only wait for the time until complete drying of the surface, to produce the finishing of decking flooring.

Type "B". The peculiarity here is that, what heating pipe laid in a layer of insulation, available in the corresponding slots. Thereafter flooring made of aluminum plate with a waterproofing layer, concrete mortar is poured on top of the resulting "cake".

Type "C". The solution was poured into two layers. In the first, located closer to the bottom, heating pipe located, then runs the separating layer. Over the last produced another casting solution for robust design.

Specific device embodiment warm floor with concrete screed will depend on certain conditions, use the materials and requirements.

Materials and tools

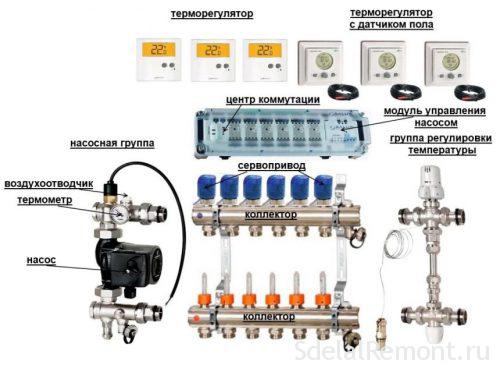

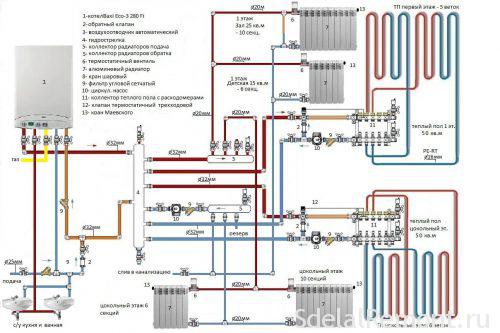

The system of floor heating with concrete screed requires the purchase of a specific set of materials for work. With a coupler and everything is clear, that you can prepare a solution on their own, or buy ready-mix, which will be diluted with a certain amount of water. The most important thing to stick to technology and accurate proportioning getting quality potting. Most of the material is required for the warm water floor, which include:

- Boiler for heating the heat carrier.

- Fitting, employees effective laying direction from the boiler along the entire length of floor heating. In addition, they are required to connect all the components together, as well as to the collector.

- ball valves, pressurization pump. They can be purchased individually, but more often they are basic equipment purchased boiler.

- Manifold group together with compartment.

- Directly tubes material selected from, that will be installed in the future of concrete screed.

Automated underfloor heating control system

As for the pipes, the most effective are because of XLPE. All other options or inferior in quality or significantly higher cost, which is not always fun begins builders. their choice, diameter, length and other parameters are selected individually, based on the destination of the floor heating can be calculated or online calculator water underfloor heating.

Preparatory stage

In the initial stages of work on the floor heating unit on the concrete foundation should be carried out a number of actions, which will be very important for the further stages. the entire system is calculated for a particular room, the number of elements and components.  Important given boiler power. It should not work for wear at maximum settings, and have little margin. Only in this case it can serve for a long period.

Important given boiler power. It should not work for wear at maximum settings, and have little margin. Only in this case it can serve for a long period.

The system defined temperature should be maintained, to be attained and to create conditions in the device of warm water floor. Based on the parameters of the room, Lots will be determined with the greatest heat loss. They can be arranged in the best way, put new windows and the doors, take other measures. But still, the outer walls of the room will lose more heat, than the rest. In this case, the main thing to choose the right distribution scheme pipeline, as well as well-decomposed pipes exposed step.

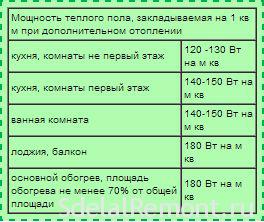

Power underfloor slightly increased in the following cases:

- Location of the room on the first floor, as well as the top floor of the house.

- Using certain floor covering in the form of slabs of marble or granite, having a substantial thickness. Some materials for the flooring on the floor have increased heat capacity indicators, that also applies to the entire system of higher power.

- A large number of windows in the room. Among these include terraces, balcony, oriel.

- Inside walls have a slight thickness.

In any case, it is better to get rid completely of the floor covering, Previously Held in the room, as well as the possibility of dismantling the old screed. The base under floor heating must be aligned to the maximum. Allowed height difference, but not more than 10 mm. If the error where large, better to think about the complementary variant ties prior to all other works. Otherwise it is encountered with such defects underfloor, as the airing of the entire system.

"Pie" Devices

to concrete screed for warm water floor was of high quality, You must be lined up all the other layers are sequentially and without departing from the technology.

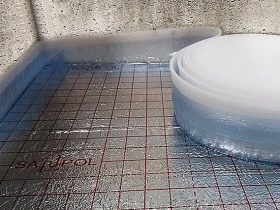

After that, as a base surface is ready for further action, arranged insulating layer.  Its main purpose - the preservation of warmth and redirect it in the opposite direction, that is, the floor covering and further into the room. The choice of material for the insulation it is oriented to the maximum thickness. Everything will depend on the conditions in the room, its position relative to the entry-level home, as well as slabs. Minimum tie layer must be 3 cm. importance is the density of the material, least 35 kilograms per square meter. Popular materials such, as polystyrene or penoplex. The finished mats, specially designed for the device of warm water floor, there are already built-in slots, where you can place all the elements of the pipeline with the selected step. Installation in this case be carried out much faster and easier. If the thermal load increases, it should be considered to increase the thickness of the insulation layer.

Its main purpose - the preservation of warmth and redirect it in the opposite direction, that is, the floor covering and further into the room. The choice of material for the insulation it is oriented to the maximum thickness. Everything will depend on the conditions in the room, its position relative to the entry-level home, as well as slabs. Minimum tie layer must be 3 cm. importance is the density of the material, least 35 kilograms per square meter. Popular materials such, as polystyrene or penoplex. The finished mats, specially designed for the device of warm water floor, there are already built-in slots, where you can place all the elements of the pipeline with the selected step. Installation in this case be carried out much faster and easier. If the thermal load increases, it should be considered to increase the thickness of the insulation layer.

Be sure to read about choosing the right substrate for underfloor.

The entire perimeter of the walls of the damper attached tape, designed to compensate for thermal expansion of ties in the future work of the floor heating system. After the heat-insulating sheathing layer made of polyethylene film styling, serves as an additional waterproofing layer.

The entire perimeter of the walls of the damper attached tape, designed to compensate for thermal expansion of ties in the future work of the floor heating system. After the heat-insulating sheathing layer made of polyethylene film styling, serves as an additional waterproofing layer.

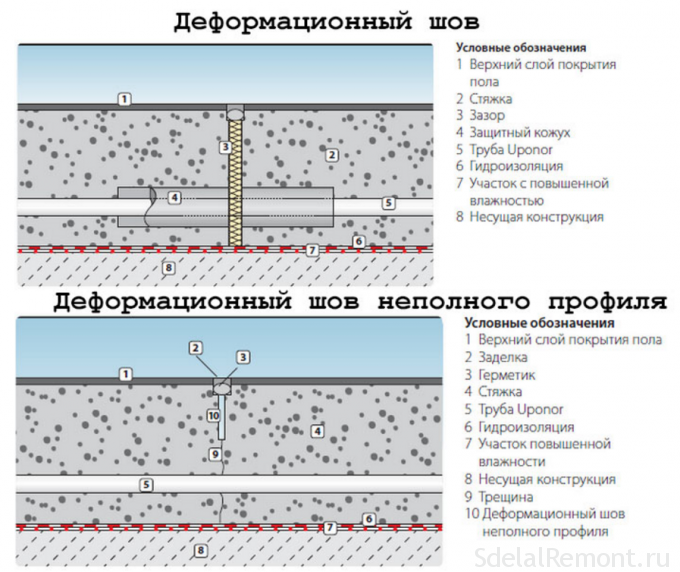

We can not forget about the layer reinforcement. It addition to its main purpose may be used for fastening pipes, if there are no special fasteners. Arranged expansion joints have to be protected in a reliable manner. Most often, in this case using a corrugated tube. It is important not to forget that for large areas and connections between rooms do expansion joints.

Selection of piping circuit

The pipes must not be laid on the surface just before screed. The most commonly used special schemes, known as "snail" or "snake". In addition there is also a combination of these options in order to achieve maximum efficiency of heat transfer from the floor heating system.

It is important to calculate the amount of tubes, which is necessary to perform the installation. Roughly every square meter requires about 5 meters of pipe, if the stacking step is 20 cm. currently it has a large number of computer programs, allowing to design any loop version for the entire circuit. For a lot of floor space is best to have several circuits, to warm air from the floor was the highest and uniform over the entire area. In this case, the most commonly used scheme "snail". There are alternated with each other opposite the system streams (hot and cold).

test

When everything is arranged to fill concrete screed check the efficiency of underfloor heating systems, as well as the correct connection of all components with each other. This so-called hydraulic tests. Stage is very important for novice builders, when there is no adequate experience of work.

The pressure in the system is started up gradually. Sealed tube should be excellent. If all goes well, run the maximum pressure, which also must be maintained throughout the system, warm water floor. Upon detection of defects of work, they should at the same time eliminate the. It may be necessary to replace all the individual sections of the pipeline to the next stage. You can not be lazy, since all these errors show up in the course of operation of the system, and will have to dismantle the flooring area and ties for repair.

screed

The latest stage of the device water underfloor heating with screed - solution casting and its distribution over the entire surface. It is worth remembering the minimum thickness of a screed, to be about 3-10 see lay pipeline system level. If necessary, obtaining the maximum flat surface made installation of beacons on the area in the room after laying pipes.  In the following will only distribute the solution generally using.

In the following will only distribute the solution generally using.

The drying process concrete screed is about 4 weeks. The system is water floor heating must not be carried out. The system can be run after the full drying period. Heating should be uniform. The maximum temperature level indicators should account for no earlier than the third day.

The result will only cover the surface of the selected one of flooring. This can be not only popular among the majority of builders ceramic tile, but the laminate, parquet or linoleum.

If you comply fully with floor heating device technology with a concrete screed, you will eventually get a really quality system, which is capable of warm air at a desired level in the room. At the same time significantly reduce the cost of heating, and create comfortable conditions for the stay in the room.