For floor heating in the end in any case have to organize topcoat, including screed. self-leveling mixtures can be used in their as, and solutions on the basis of cement-sand. All will depend on the financial capabilities and the selected option device. In any case, the surface should get perfectly flat, including with respect to the circuit level of the water floor heating. In this case, the sub-floor heating will be uniform across the surface in the room. It is worth paying attention to one very important point, which is the optimum thickness of a future tie.

Common features

The thickness of screed to water underfloor heating It will affect the efficiency of the system actions, its effectiveness, as well as the operational period. A thin layer will not allow a uniformly warm the ground floor, And besides, this tie very quickly crack due to constant fluctuations of temperature modes. Very quickly will become worthless and the selected flooring at very thin screed.

But also thick fill layers will not bring positive result. With such base greatly increase the cost of heating, as it is necessary to spend a lot of energy to warm up all the resulting "cake". Consequently, it is necessary to select the optimum performance level of pouring the concrete ties for water system underfloor heating. But even the experts can not give an answer to the universality of the thickness of the fill solution. Many conditions can have an impact on this parameter:

- Type of subfloor, type of soil. Mostly it refers specifically to the particular construction of the regeneration of the premises concrete floor from the ground up.

- Parameters of the entire premises, which is arranged strainer warm water over the floor, its configuration.

- Purpose of the future premises.

These items are among the main. Additionally, it may be a few more nuances, which you should pay particular attention. They can be described as marking cement used, selection of a particular mixture for, armature and its characteristics, etc..

varieties ties

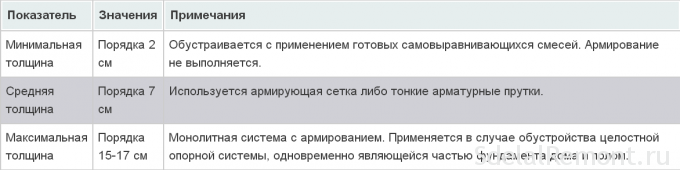

In total, there are three basic types of ties, which may be useful to create a flat surface on top of the installed water underfloor. But even this classification is considered a conditional.

- The thickness of the floor heating water floor, or rather ties the whole system in the area 20 mm.

This is higher than the minimum rate for fill over circuit pipeline underfloor heating. In the self-leveling compounds are most often used, that allow you to really fine surface, able to withstand significant mechanical loads and impact. This step is arranged without application layer reinforcement or reinforcing mesh.

This is higher than the minimum rate for fill over circuit pipeline underfloor heating. In the self-leveling compounds are most often used, that allow you to really fine surface, able to withstand significant mechanical loads and impact. This step is arranged without application layer reinforcement or reinforcing mesh. - Averages the fill level, which vary between 70 mm. Additionally for imparting structural strength and reliability of the used reinforcing mesh or grid for special reinforcement ties.

- Maximum limits of a future tie level pipes underfloor reach 150-170 mm. The system is called a monolithic, which compulsorily apply reinforcement. Suitable for use in an integrated support system apparatus, serving not only as a subfloor, but also the foundation of the future structure. In this case, pre-learn, what kind of load can withstand the floor at home.

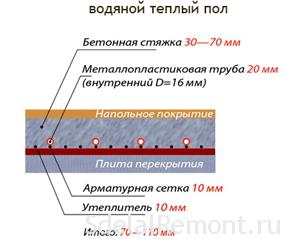

But it is impossible to attribute all the indicators for the minimum or maximum value of the fill level of the screed. After all, if the additional use gravel, the doorstep of 20 mm should forget. The total thickness of the fill underfloor heating is much more. Self-leveling compounds are typically used just before, how to produce flooring flooring. To do so it is necessary to precisely, the entire outline of warm water was covered with a floor screed. This indicates, that selecting pipe diameter of about 2.5 cm, it will be enough to fill layer 50-70 mm. It is up to 50 mm thickness of screed to be laid over the pipes.

minimum performance

According to generally accepted standards have minimum thickness of indicators screed of the system of floor heating water type. according to them,, in the case of self-leveling compounds, as mentioned earlier, screed must be at least 20 mm. But if the solution is prepared from sand and cement, the, least 40-50 mm. In the latter case, it concerns fill without additional reinforcement layer. If you make it smaller, these parameters, it is unlikely to succeed to achieve the effectiveness of the work, and obtain the desired characteristics.

There are a few cases, in which one can think of the minimum values levels of screed over underfloor heating. It is mandatory to be arranged subfloor, which the leveled base to a horizontal position. All significant irregularities are eliminated and thus can only create a layer of floor heating loop. In addition, the entire structure must be no reinforcement elements. This will only increase the total fill layer. Instead valves have advanced means to make the solution strength and yield - fibrovolokno. It has many positive qualities, are worth paying attention to.

If the room in a subsequent substantial burden on the subfloor will be created during operation, the minimum values of the thickness of the screed must escape toward. These facilities may be considered corridors, Bathrooms, toilets, food, any technical premises.

Building regulations say, that the pipes floor heating will be the most efficient transfer of heat into the room with the presence of ties 65 mm with flooring.

maximum limits

There are no standards in the fill to the maximum screed is not provided. Technologically it is possible to arrange a height of 10-15 cm. If do layer more, then no efficiency, it will not bring. All the work carried out will be meaningless. But this tie can be done only in exceptional cases. Such situations may be the following points:

- If hosted layer acts not only as a fill screed, but also as the foundation structure.

- concrete floor casting device in rooms with considerable loads (garage).

- Implementation of the installation screed on problem soils, that is more suitable for private homes.

If the subfloor have significant elevation, some artists decide to do as much as possible fill, all lead to a horizontal position. But the feasibility of this no-no. It is best to pre make the filling dry materials (expanded), then produce a fill solution. These actions will save time on work, as well as funds for materials. true, all this is best done before the device water floor heating. Heating main requires a flat surface for even heat distribution across the base floor in the room. In the presence of large protrusions on the surface, they can do to knock down with a hammer or other equipment.

A large number of poured concrete will be spent in the shuffle. If we have a room in the 10 square meters, a tie layer will be only 100 mm, it will take at least a cubic meter of concrete, and it is unreasonable costs.

Can with a thick headband over Radiant floor appear and other difficulties:

- The long period of the heating surface.

- Reduce the effectiveness of the system operation.

- Increase the cost of heating the room.

This all suggests that, that should choose the optimal parameters for the thickness of the screed floor warm water, to all the characteristics of the system manifested and well maintained throughout the life of the.

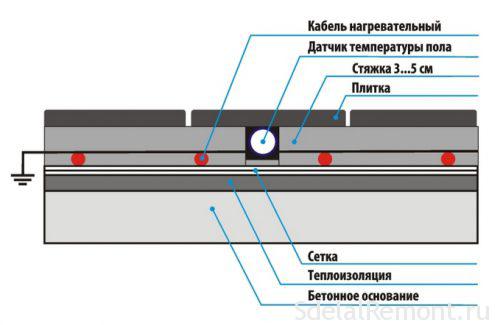

"Pie" warm floor

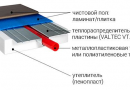

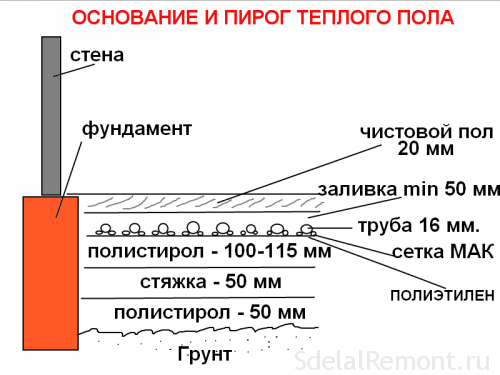

The "pie" underfloor heating, but, Consequently, in total thickness, and other parameters are, except for the screed:

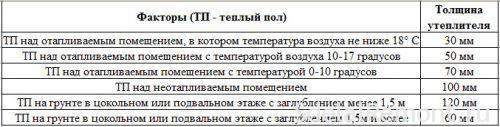

- thermal insulation. Most often, it is used as a polystyrene. The layer is required to, not to spend too much heat, not to give it down, and forwarded to the base floor. The system is becoming less expensive and more effective. If it's cold regions, the optimal thickness should be about polystyrene 100 mm. In warmer conditions will be sufficient 50 mm. Much in this case will depend on the room arrangement (above the basement, heated room, etc.).

- waterproofing. The total thickness of it can never be taken into account due to the fact, that most often it is a usual film of polyethylene.

Its thickness is so small, that makes no sense to take it into account.

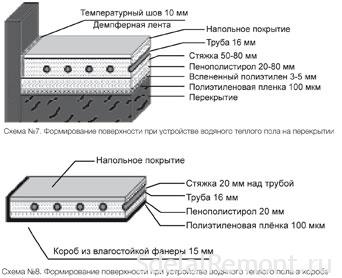

Its thickness is so small, that makes no sense to take it into account. - MAK Grid provides a qualitative and distribute the tube warm water floor. Its optimal thickness is 4 mm. But without it you can do in that case, if carried out under the system installation base mat with corresponding projections for underfloor heating circuits.

- used pipe. It was from her and will spread the heat around the base. Usually its height is no more than 20-25 mm, depending on the diameter of the inner part.

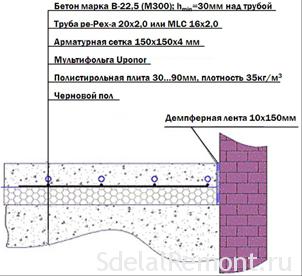

- Concrete screed. To prepare the solution best thing to do is not very strong solution to the brand M300. fill level should vymeryat from the top of the laid pipe. In this case, the warm water system of the floor will work most efficiently.

- Finishing coating. In addition to the floor covering in total thickness accrue adhesive, if a tile.

You can do some preliminary calculations on the thickness of the screed for underfloor heating water, depending on the embodiment of floor covering. For thermal insulation will be sufficient 50 mm, unless it is a cold region of the country. Trumpet with MAA grid, necessary to secure the circuit takes the average 25 mm. All will depend on the diameter of the pipe. In some cases, the MAC will mesh is not necessary, if the selected base mats, specially designed for the flooring under floor heating. The optimum thickness of the whole tie will 50 mm, and for finish coating will be approximately 20 mm. Total we have, that the total thickness of the system is received within 140-145 mm. This layer is necessary for the device on the first floor. If it is the second and subsequent floors, then there will be some reduction of the design through a layer of smaller heater. His many there just will not be required.

Tips for filling

For fill ties of water underfloor heating system should follow the recommendations from the experts, with experience in this type of work. In particular this applies to cement brand, which is the optimal mode is equal to M200-M300. Not more than will the various additives in the solution, to improve the quality of the fill. plasticizer It allows the mixture to spread perfectly over the entire surface and at the end to avoid the appearance of cracks and other defects.

After pouring must be maintained during complete drying of the solution to. During this period can not be included in the operating state Radiant Floor, as it will have a negative effect on the drying process and the quality of the screed. To be given a strong, should be to care for the tie after casting. This is to maintain the optimal temperature conditions, exclude drafts, as well as wetting the surface for almost a week.

Heated "warm" floor should not be, to speed up the drying process. If time is running out, it is better to use the other options already subfloor device, such as self-leveling mixture, where dry spent about 9-11 days. At the time of mounting the screed ambient temperature must not fall below +10. Otherwise, a positive result will not be able to get.

We must not forget, not only about the damping tape, serving as thermal expansion compensator screed, but also about all the other layers, that will create a solid design of the system of warm water floor. Until the start of the casting should take measures to verify the system performance and integrity of all connections. Otherwise, it may be difficult after the screed.

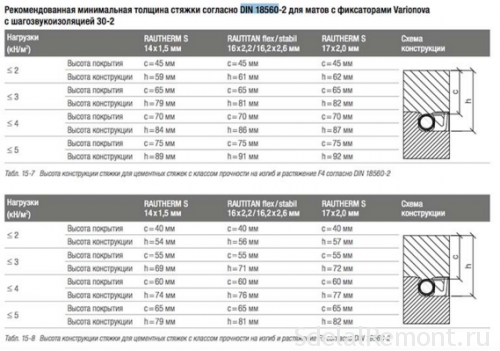

manufacturer's recommendations

Every manufacturer is different evaluates its mix and other materials for the device warm floor of the contour, as well as ties in concrete. In addition, they present their recommendations on the choice of quality and optimal fill level, system to have the highest efficiency.

Rehau. For them from the top of floor heating system pipes must be maintained within the thickness of the solution 45 mm. And the whole structure - no more 61 mm. Consequently, it is necessary to choose the right to fill all the required diameter of the pipeline. But when it comes to industrial premises and the presence of constant maximum loads, the minimum concrete screed must be 75 mm and the maximum reach 92 mm.

can. It also refers to a number of manufacturers from Germany. They also point to the need for grout along the upper edge of the pipe system warm water to the height of the floor 45 mm. If we consider these figures directly from the insulation, the 65 mm. You can refer to the company's products and add to the composition of their corporate plasticizer solution. In this case it is possible to reduce the height of the concrete ties to 25 mm. The catalog shows all the recommendations, depending on the material used and the total area.